How Enhanced Oil Recovery Techniques Improve Onshore Production

In the ever-evolving landscape of the oil and gas industry, maximizing the recovery of hydrocarbons from existing reservoirs is a paramount objective. While primary and secondary recovery methods form the bedrock of oil extraction, a significant portion of the original oil in place (OOIP) often remains trapped underground. This is where Enhanced Oil Recovery (EOR) techniques come into play, offering a suite of advanced methods to unlock these stranded assets and breathe new life into mature onshore oilfields. This comprehensive blog post will delve into the intricacies of EOR, exploring the various techniques, their profound impact on onshore production, and the economic and environmental considerations that shape their deployment.

The journey of oil extraction from a reservoir typically unfolds in three distinct phases. Primary recovery relies on the natural pressure within the reservoir to drive oil to the surface. As this natural pressure dissipates, secondary recovery methods, most commonly water or gas injection, are employed to maintain pressure and sweep additional oil toward production wells. However, even after these initial phases, a substantial amount of oil, often between 50% to 70% of the OOIP, can be left behind. EOR, also known as tertiary recovery, targets this remaining oil, utilizing sophisticated technologies to alter the properties of the oil or the reservoir itself, thereby facilitating its extraction.

The Oil Recovery Techniques

EOR is not a one-size-fits-all solution. The selection of an appropriate technique is a complex decision, heavily dependent on reservoir characteristics such as rock type, permeability, porosity, oil viscosity, and depth. The three primary categories of EOR methods are thermal recovery, gas injection, and chemical injection.

Thermal Recovery: Turning Up the Heat

Thermal recovery methods are the most established and widely applied EOR techniques, particularly effective in reservoirs containing heavy, viscous oil. By introducing heat into the reservoir, these methods reduce the oil’s viscosity, making it more mobile and easier to produce.

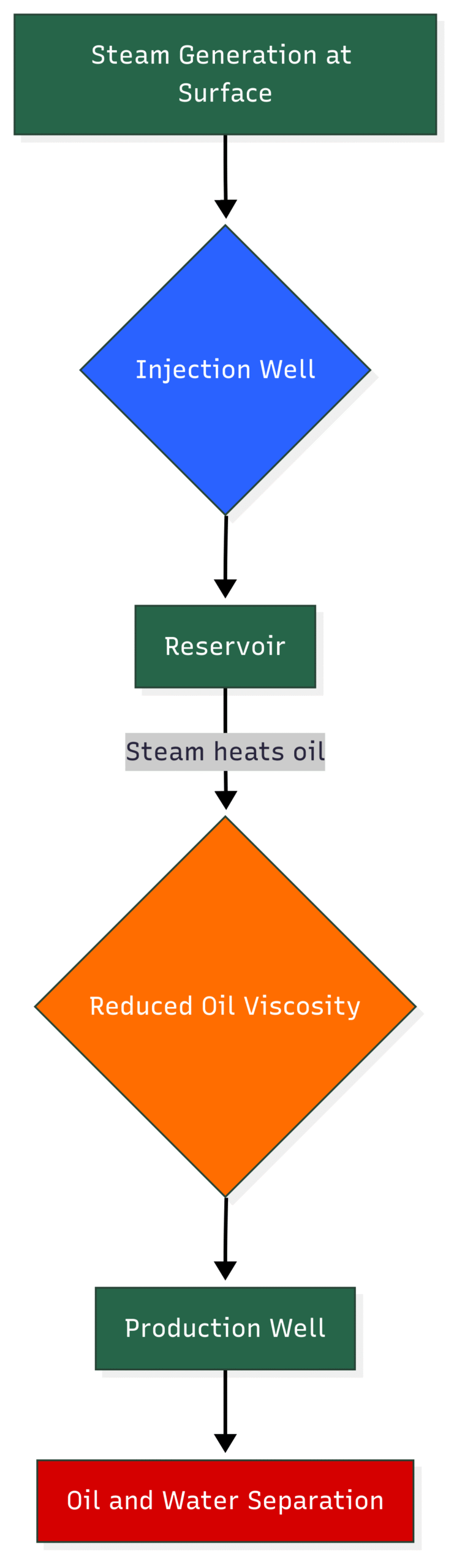

Steam Injection

Steam injection is the most prevalent form of thermal EOR. It involves generating steam at the surface and injecting it into the reservoir. There are two main approaches to steam injection:

Cyclic Steam Stimulation (CSS), also known as “huff and puff,” involves injecting steam into a production well for a period, then allowing the well to “soak” for a time to heat the surrounding oil. The same well is then used to produce the heated, less viscous oil. This cycle can be repeated multiple times.

Steamflooding is a more continuous process where steam is injected into dedicated injection wells to create a “steam zone” that pushes the heated oil towards production wells.

In-Situ Combustion

In-situ combustion, or fireflooding, is a more complex thermal method where a portion of the reservoir’s oil is ignited. The controlled combustion process generates heat, which reduces the viscosity of the surrounding oil. The combustion front and the hot gases produced help to drive the oil toward production wells.

Gas Injection: A Miscible Approach

Gas injection EOR involves introducing various gases into the reservoir to improve oil recovery. The primary mechanism can be either miscible or immiscible displacement. In miscible displacement, the injected gas dissolves in the oil, causing it to swell and reducing its viscosity. In immiscible displacement, the gas acts as a piston, pushing the oil towards the production wells.

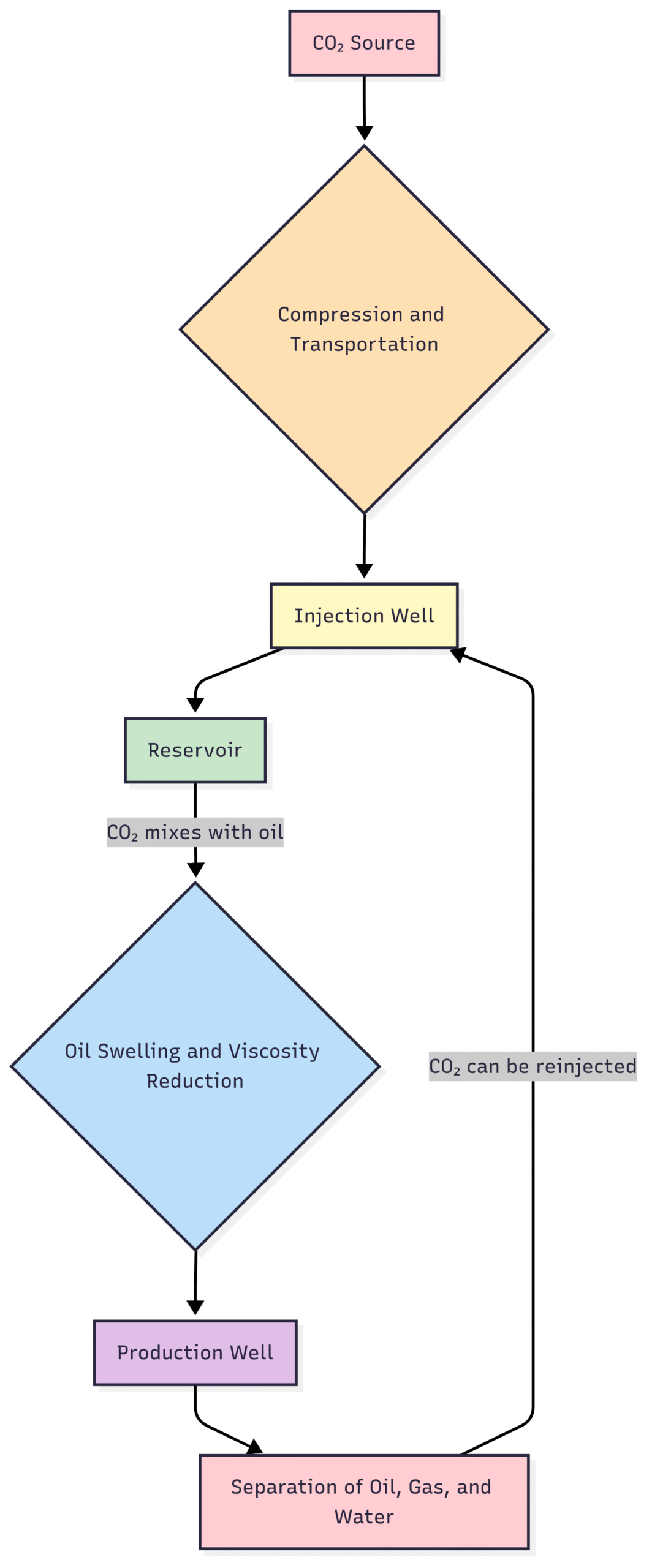

Carbon Dioxide (CO₂) Injection

CO₂ injection is the most common type of gas EOR. When injected at high pressure, CO₂ becomes a supercritical fluid, a state that allows it to mix with and displace the oil effectively. A significant advantage of CO₂ EOR is its potential for carbon capture and sequestration (CCS), where the injected CO₂ remains permanently stored in the reservoir, mitigating greenhouse gas emissions.

Hydrocarbon Gas Injection

Natural gas, primarily methane, and other hydrocarbon gases can also be used for EOR. These gases are often readily available in oil-producing regions and can be effective in achieving miscibility with the reservoir oil.

Nitrogen Injection

Nitrogen is another gas used for EOR, particularly in deeper, high-pressure reservoirs. It is less expensive than hydrocarbon gases but typically requires higher pressures to achieve miscibility.

Chemical Injection: Altering the Interfacial Properties

Chemical EOR methods involve injecting specialized chemical solutions into the reservoir to improve the displacement of oil by water. These techniques are particularly useful in reservoirs where waterflooding has become inefficient.

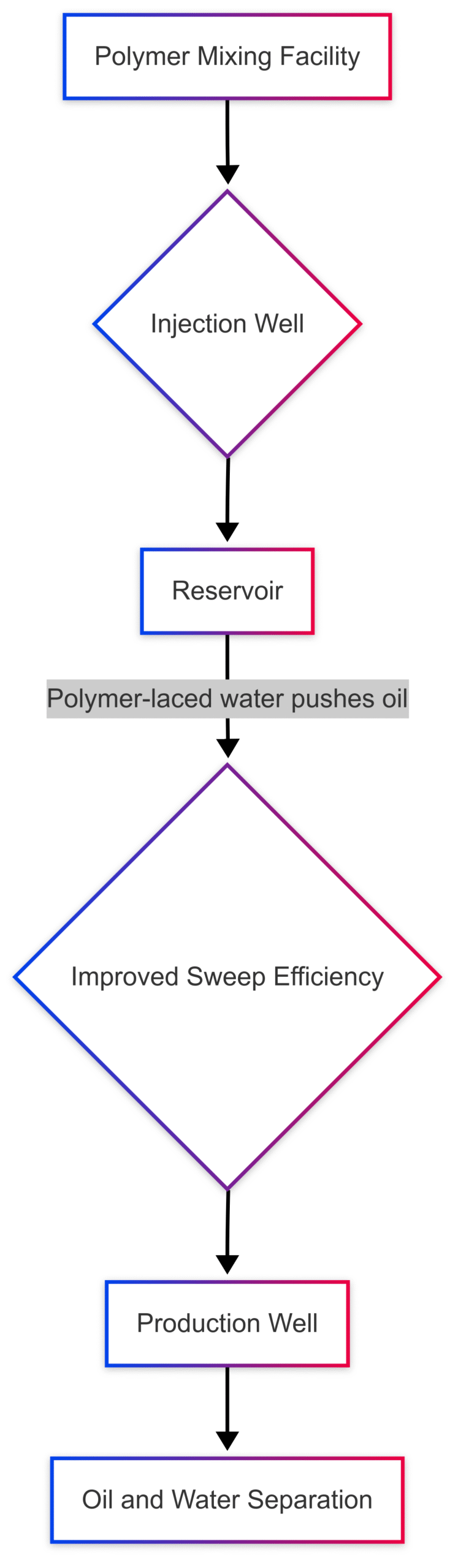

Polymer Flooding

In polymer flooding, long-chain polymer molecules are added to the injection water. This increases the viscosity of the water, improving the sweep efficiency and preventing the water from “fingering” through the more permeable zones of the reservoir, thus pushing a more uniform front of oil towards the production wells.

Surfactant Flooding

Surfactants, the primary components of soaps and detergents, are used in this method to reduce the interfacial tension between oil and water. This reduction in tension allows the water to more effectively “wash” the oil from the reservoir rock.

Alkaline Flooding

Alkaline chemicals, such as sodium hydroxide, are injected to react with certain types of crude oil to form surfactants in-situ. This in-situ surfactant generation reduces interfacial tension and can also alter the wettability of the reservoir rock, making it more favorable for oil recovery.

ASP (Alkali-Surfactant-Polymer) Flooding

This is a combination of the three chemical methods. An ASP flood leverages the synergistic effects of all three chemicals to achieve a higher oil recovery rate than any single method alone. The alkali reacts with the oil to create soap, the surfactant further reduces interfacial tension, and the polymer improves the sweep efficiency of the injected fluid.

The Onshore Production Revolution: Benefits of EOR

The implementation of EOR techniques in onshore oilfields has a transformative impact, leading to a multitude of benefits that extend beyond simply increasing production volumes.

Maximizing Resource Recovery and Extending Field Life

The most significant advantage of EOR is its ability to unlock substantial volumes of oil that would otherwise be left in the ground. By recovering an additional 10% to 30% or more of the OOIP, EOR can dramatically increase the ultimate recovery from a field. This not only boosts production rates in the short term but also extends the economic life of mature oilfields, deferring the need for costly decommissioning and abandonment. For many onshore regions with a long history of oil production, EOR represents a critical strategy for sustaining output and ensuring long-term energy security.

Economic Viability and Profitability

While EOR projects require significant upfront investment in infrastructure and injection fluids, the incremental oil production they generate can be highly profitable, especially in an environment of stable or rising oil prices. The economic viability of an EOR project is a careful balance between the cost of implementation and the value of the recovered oil. Advances in technology and a better understanding of reservoir behavior are continually improving the cost-effectiveness of these techniques. Furthermore, extending the life of existing infrastructure through EOR is often more economically attractive than exploring for and developing new fields.

Environmental Considerations and Opportunities

The environmental impact of EOR is a nuanced topic. On one hand, the injection of chemicals and the energy-intensive nature of thermal methods can have environmental footprints. The potential for groundwater contamination and the greenhouse gas emissions associated with steam generation are valid concerns that require careful management and regulatory oversight.

However, EOR also presents significant environmental opportunities. CO₂ EOR, in particular, offers a direct pathway for carbon capture, utilization, and storage (CCUS). By utilizing captured CO₂ from industrial sources, such as power plants and manufacturing facilities, CO₂ EOR projects can permanently sequester large volumes of this greenhouse gas in geological formations. This dual benefit of enhanced oil production and carbon mitigation makes CO₂ EOR a particularly attractive option in the transition to a lower-carbon energy future.

Technological Advancement and Innovation

The pursuit of more efficient and cost-effective EOR methods drives continuous innovation in the oil and gas industry. Research and development in areas such as nanotechnology, advanced polymers, and reservoir simulation software are constantly pushing the boundaries of what is possible. For instance, nanoparticles are being investigated for their potential to improve the delivery of chemicals and heat to target zones within the reservoir. These technological advancements not only benefit the oil and gas sector but can also have applications in other fields, such as environmental remediation and water treatment.

Challenges and the Road Ahead for Onshore EOR

Despite the significant benefits, the widespread implementation of EOR is not without its challenges.

High Initial Costs and Economic Risks

The capital expenditure required for EOR projects can be substantial. The costs of steam generation facilities, CO₂ pipelines, and chemical injection plants can be a significant barrier to entry, particularly for smaller operators. The economic success of an EOR project is also sensitive to oil price volatility. A sharp decline in oil prices can render a project unprofitable, making investment decisions a complex risk assessment.

Reservoir Complexity and Heterogeneity

No two oil reservoirs are alike. The geological complexity and heterogeneity of many onshore fields pose a significant challenge to the effective implementation of EOR. Characterizing the reservoir accurately is crucial for designing an optimal EOR strategy. Inadequate understanding of fluid flow paths and reservoir properties can lead to poor sweep efficiency and lower-than-expected oil recovery.

Environmental and Regulatory Hurdles

The environmental risks associated with EOR, such as potential water contamination and induced seismicity, necessitate stringent regulatory frameworks. Obtaining permits and complying with environmental regulations can be a lengthy and complex process. Public perception and community acceptance are also critical factors that can influence the viability of onshore EOR projects.

The Future is Enhanced

Looking ahead, the future of onshore oil production is inextricably linked to the continued development and deployment of enhanced oil recovery techniques. As conventional oil reserves become more challenging to find and develop, the ability to maximize recovery from existing fields will become increasingly vital. The convergence of advanced technologies, a growing focus on environmental stewardship, and the economic imperative to unlock stranded assets will undoubtedly fuel the expansion of EOR in the years to come. Through a combination of scientific ingenuity and responsible resource management, enhanced oil recovery will continue to play a pivotal role in powering our world while shaping a more sustainable energy future.