How Functional Safety Prevents Industrial Accidents

In the complex and often hazardous world of industrial operations, the specter of accidents looms large. From chemical spills and equipment malfunctions to catastrophic explosions, the potential for disaster is an ever-present reality. While headlines often focus on the immediate aftermath of such incidents – the environmental damage, financial losses, and tragic human cost – a quieter, more proactive discipline works tirelessly behind the scenes to prevent these events from ever occurring. This discipline is known as functional safety, and it is the bedrock upon which modern industrial safety is built.

This comprehensive blog post will delve into the world of functional safety, exploring its core principles, methodologies, and the critical role it plays in preventing industrial accidents. We will journey through the safety lifecycle, dissect the components of a safety instrumented system, and understand how layers of protection are built to create a robust defense against hazards.

What is Functional Safety?

At its core, functional safety is the part of the overall safety of a system or piece of equipment that depends on the correct functioning of its safety-related systems. In simpler terms, it’s about making sure that the automatic safety systems designed to protect people, the environment, and the industrial process itself work exactly as intended, when they are needed most.

Unlike general safety measures, which might include things like hard hats, safety harnesses, or operational procedures, functional safety deals specifically with active safety systems. These are systems that automatically detect a potentially dangerous condition and execute a pre-determined action to bring the process to a safe state. Think of an automatic emergency shutdown system in a chemical plant that activates when a pressure vessel exceeds its safe operating limit, or a light curtain that stops a robotic arm when a person enters a hazardous area.

The fundamental principles of functional safety revolve around a systematic and quantifiable approach to risk reduction. It is not enough to simply believe a safety system will work; functional safety demands a rigorous, evidence-based process to ensure it. This involves:

Identifying Hazards: Understanding what can go wrong in a process.

Assessing Risks: Evaluating the likelihood and severity of the identified hazards.

Defining Safety Functions: Specifying what the safety system must do to mitigate the risks.

Assigning a Safety Integrity Level (SIL): Quantifying the level of risk reduction required from a safety function.

Designing and Implementing the System: Building the safety system to meet the specified SIL.

Verification and Validation: Ensuring that the implemented system meets the safety requirements.

Operation and Maintenance: Maintaining the integrity of the safety system throughout its operational life.

This structured approach ensures that safety is not an afterthought, but an integral part of the entire system lifecycle.

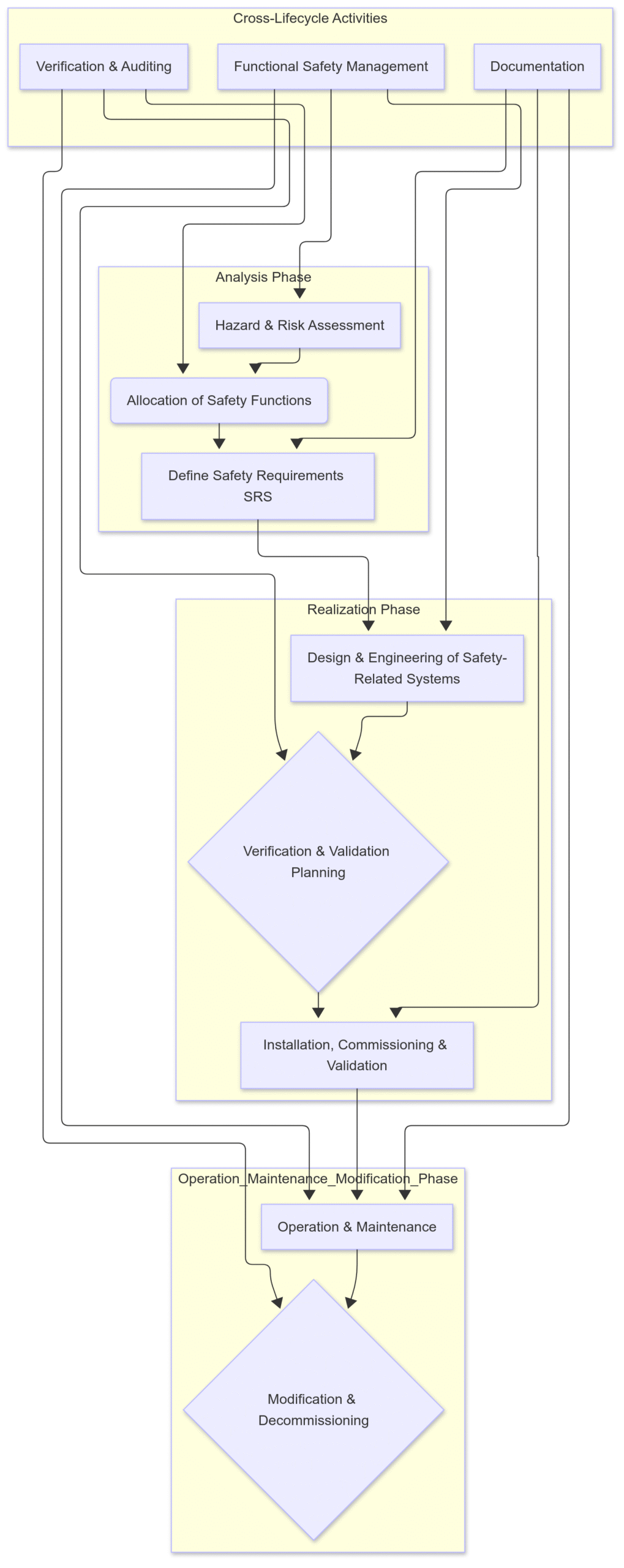

The Functional Safety Lifecycle

Functional safety is not a one-time activity but a continuous process that spans the entire life of a system, from its initial conception to its eventual decommissioning. This process is known as the safety lifecycle, and it provides a structured framework for managing safety-related activities. While different industry standards may have slight variations, the core phases of the safety lifecycle are generally consistent.

1. Hazard and Risk Assessment: The lifecycle begins with a thorough analysis of the process or system to identify potential hazards. Techniques like Hazard and Operability studies (HAZOP) are often employed to systematically scrutinize the design and identify potential deviations from normal operation that could lead to hazardous events. Once hazards are identified, the associated risks are assessed to determine their potential severity and likelihood of occurrence.

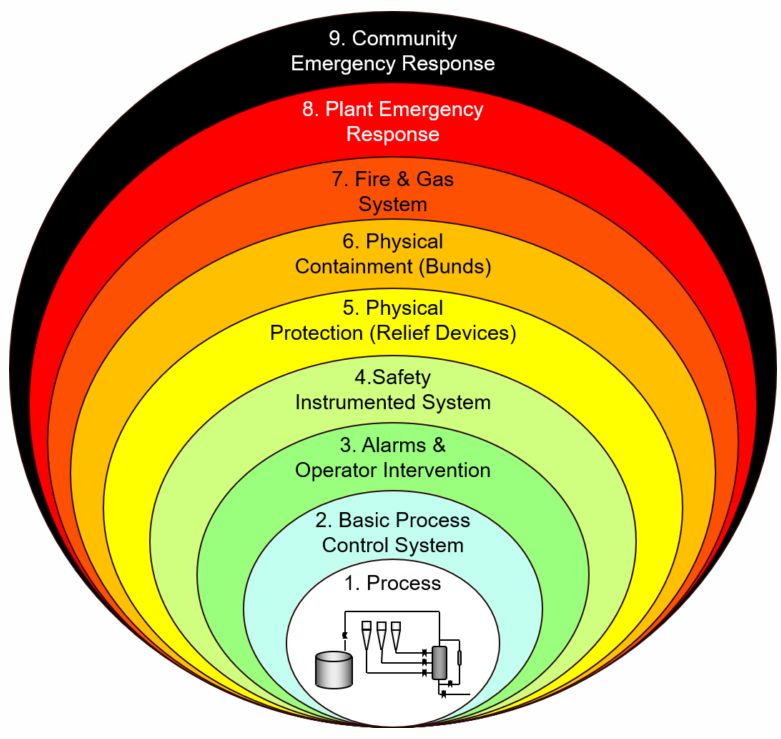

2. Allocation of Safety Functions to Protection Layers: No single safety measure is foolproof. Therefore, functional safety employs a multi-layered approach to risk reduction. This phase involves deciding which protection layers are needed to mitigate the identified risks. These layers can range from the basic process control system (BPCS) to more robust safety instrumented systems (SIS) and even physical protection measures like pressure relief valves.

3. Safety Requirements Specification (SRS): This is arguably the most critical document in the safety lifecycle. The SRS details exactly what each safety function must do, the conditions under which it must act, and the performance level required (the SIL). A well-written SRS is clear, unambiguous, and provides a solid foundation for the design and implementation of the safety system.

4. Design and Engineering: With the SRS as a guide, engineers design and build the safety system. This involves selecting appropriate sensors, logic solvers, and final elements (like valves or motors) that, when combined, can achieve the required SIL. The design phase also considers factors like redundancy, fault tolerance, and diagnostic capabilities.

5. Installation, Commissioning, and Validation: Once the system is built, it must be installed and commissioned correctly. The validation phase is where the system is rigorously tested to confirm that it meets all the requirements laid out in the SRS. This is the final check to ensure that the safety system will perform as expected in a real-world scenario.

6. Operation and Maintenance: The safety lifecycle doesn’t end after commissioning. Over the operational life of the plant, the safety system must be regularly maintained, tested, and inspected to ensure it remains in a state of high integrity. This includes periodic proof testing to detect any hidden failures that could compromise its ability to function.

7. Modification: If any changes are made to the process or the safety system, a formal management of change process must be followed. This ensures that the impact of the changes on safety is properly assessed and that the integrity of the safety system is not compromised.

8. Decommissioning: Even at the end of its life, a system must be decommissioned safely. The safety lifecycle includes procedures for taking a system out of service without introducing new hazards.

Safety Instrumented Systems (SIS)

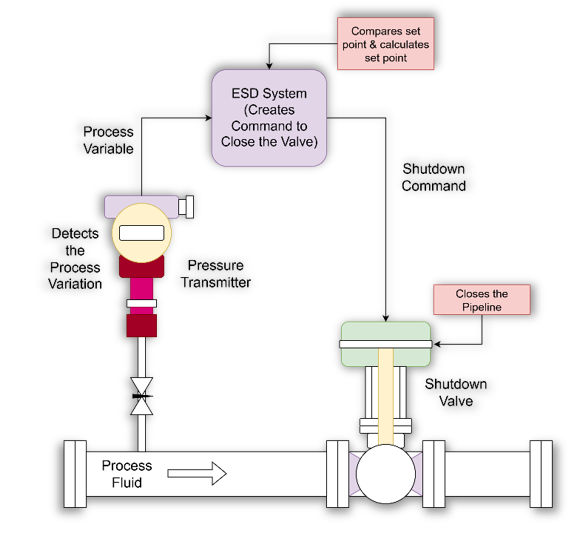

At the heart of functional safety in many industrial settings is the Safety Instrumented System (SIS). An SIS is an independent system composed of sensors, logic solvers, and final elements, designed to carry out one or more safety instrumented functions. It acts as a vigilant guardian, constantly monitoring a process and taking automatic action to prevent a hazardous event from occurring or to mitigate its consequences.

The key components of an SIS are:

Sensors: These are the eyes and ears of the SIS. They measure process variables like pressure, temperature, flow, and level. In a safety context, these sensors must be highly reliable and often redundant to ensure that a single sensor failure does not lead to a failure of the entire safety function.

Logic Solver: This is the brain of the SIS. It receives input from the sensors and executes the pre-programmed logic defined in the Safety Requirements Specification. If the logic solver determines that a dangerous condition exists, it sends a command to the final elements to take action. Modern logic solvers are typically certified safety PLCs (Programmable Logic Controllers) or specialized safety relays designed for high reliability.

Final Elements: These are the muscles of the SIS. They are the devices that physically interact with the process to bring it to a safe state. Examples include emergency shutdown valves, motors, actuators, and relays that can shut off power, open a relief path, or stop a piece of machinery.

It is crucial to understand that the SIS is independent of the Basic Process Control System (BPCS). While the BPCS is responsible for the normal day-to-day control of the plant, the SIS is dedicated solely to safety. This independence ensures that a failure in the control system, which could be a cause of a hazardous event, does not also compromise the safety system designed to protect against it.

Layers of Protection Analysis (LOPA)

To determine how much risk reduction is needed from a safety function, and thus what its Safety Integrity Level (SIL) should be, a method called Layers of Protection Analysis (LOPA) is often used. LOPA is a semi-quantitative risk assessment method that helps to determine the adequacy of the existing and proposed safeguards.

The core idea behind LOPA is that multiple independent protection layers (IPLs) are in place to prevent a hazardous event. Each layer acts as a barrier, and for an accident to occur, all of these layers must fail. LOPA analyzes each of these layers to see if they are robust enough to reduce the risk to a tolerable level.

A typical LOPA study involves the following steps:

Identify an undesired consequence: This is the specific accident scenario being analyzed (e.g., a vessel rupture).

Identify the initiating cause: This is the event that starts the accident sequence (e.g., a cooling system failure).

Estimate the frequency of the initiating cause: How often is this event expected to happen?

Identify the Independent Protection Layers (IPLs): These are the safeguards in place to prevent the initiating cause from leading to the consequence. To be considered an IPL, a safeguard must be:

Independent: Its performance is not affected by the failure of another IPL or by the initiating cause itself.

Auditable: It can be tested and verified to be functional.

Reliable: It has a known probability of failure on demand (PFD).

Estimate the PFD of each IPL: What is the probability that each protection layer will fail to work when needed?

Calculate the mitigated event frequency: By multiplying the initiating event frequency by the PFDs of all the IPLs, the frequency of the accident occurring, even with the safeguards in place, can be calculated.

Compare with the tolerable risk frequency: This calculated frequency is then compared to the company’s defined tolerable risk for that specific consequence. If the calculated frequency is higher than the tolerable frequency, then additional protection layers or a higher SIL for an existing SIS function is required.

LOPA provides a structured and logical way to make decisions about safety system design and ensures that resources are focused on the most critical risks.

Key Standards in Functional Safety

The practice of functional safety is guided by a set of internationally recognized standards. These standards provide a framework and a set of requirements for managing functional safety throughout the lifecycle of a system. The two most important foundational standards are:

IEC 61508: Functional Safety of Electrical/Electronic/Programmable Electronic Safety-Related Systems. This is the umbrella standard for functional safety and is applicable across all industries. It sets out the requirements for ensuring that systems are designed, implemented, and maintained to a high level of safety integrity.

IEC 61511: Functional Safety – Safety Instrumented Systems for the Process Industry Sector. This standard is a specific interpretation of IEC 61508 for the process industries (e.g., chemical, oil and gas, and petrochemical). It provides guidance on the application of SIS in these sectors.

Other industry-specific standards, such as ISO 26262 for the automotive industry and EN 50128 for the railway industry, are also derived from the principles of IEC 61508.

The Human Factor: Competency and Culture

While standards and technologies are essential, they are only as effective as the people who implement them. A successful functional safety program relies heavily on a strong safety culture and competent personnel.

Competency: Everyone involved in the safety lifecycle, from the engineers who design the systems to the technicians who maintain them, must have the necessary knowledge, skills, and experience. This often requires specialized training and certification.

Safety Culture: This is the shared set of values, beliefs, and behaviors within an organization that prioritizes safety. A positive safety culture encourages open communication about safety concerns, empowers employees to stop work if they feel it is unsafe, and ensures that safety is not compromised for the sake of production or profit.

Benefits of a Robust Functional Safety Strategy

The primary benefit of functional safety is, of course, the prevention of accidents and the protection of life, the environment, and assets. However, the benefits extend far beyond this:

Increased Uptime and Productivity: A well-designed safety system can help to prevent spurious trips, which can shut down a process unnecessarily, leading to lost production.

Regulatory Compliance: Adherence to functional safety standards is often a legal or regulatory requirement.

Reduced Insurance Premiums: A strong safety record can lead to lower insurance costs.

Enhanced Reputation: A commitment to safety can enhance a company’s reputation with customers, investors, and the public.

The Future of Functional Safety

The field of functional safety is constantly evolving. The increasing use of software-intensive systems, wireless communication, and the Internet of Things (IoT) presents new challenges and opportunities. The integration of cybersecurity into functional safety is becoming increasingly critical to protect safety systems from malicious attacks. Furthermore, the application of artificial intelligence and machine learning is being explored for predictive maintenance and more sophisticated hazard analysis.

Conclusion

Functional safety is a complex and multifaceted discipline, but its purpose is simple and profound: to prevent accidents. By taking a systematic, evidence-based approach to the design, implementation, and maintenance of safety systems, functional safety provides a powerful framework for managing risk in our increasingly complex industrial world. It is a testament to the power of proactive engineering and a commitment to the principle that every worker has the right to return home safely at the end of the day. Through the diligent application of the principles of functional safety, we can continue to build a safer and more secure future for all.