How to Select Level Instruments for Challenging Process Conditions: A Comprehensive Guide 🌊

Selecting the right level instrument for your industrial process is crucial for efficient operation, safety, and quality control. However, when dealing with challenging process conditions, this task becomes significantly more complex. Factors like extreme temperatures, high pressures, corrosive substances, viscous materials, turbulent surfaces, and the need to measure the interface between two immiscible liquids can render many standard level measurement technologies unreliable or even unusable.

This comprehensive guide will navigate you through the intricacies of choosing appropriate level instruments for these demanding environments. We will explore various level measurement technologies, analyze their suitability for specific challenges, and provide a structured approach to making informed decisions.

Understanding the Challenges 🌡️🧪🌪️

Before diving into specific instruments, it’s essential to clearly define the “challenging process conditions” you are facing. Each challenge presents unique obstacles to accurate and reliable level measurement:

Extreme Temperatures: High or low temperatures can affect the performance and longevity of electronic components, sensor materials, and signal transmission. Expansion and contraction of materials can also impact accuracy.

High Pressures: Elevated pressures can stress instrument housings and seals, potentially leading to leaks or malfunctions. The density of the process fluid may also be affected, influencing some measurement principles.

Corrosive Substances: Aggressive chemicals can damage wetted parts of the instrument if the materials of construction are not carefully selected. This can lead to inaccurate readings and premature failure.

Viscous Materials: Thick, sticky fluids can coat sensors, dampen signals, and cause blockages in mechanical systems. This can result in sluggish responses and inaccurate level readings.

Foaming or Turbulent Surfaces: Foam layers can obscure the true liquid level, while turbulent surfaces can create unstable readings and make it difficult for some technologies to obtain a consistent measurement.

Solids and Slurries: Measuring the level of solids or slurries presents challenges due to their varying densities, angles of repose, and potential for caking or bridging.

Dust and Humidity: In dusty environments, airborne particles can interfere with non-contact measurement technologies. High humidity can also affect electronic components and signal transmission.

Vibrations and Agitation: Mechanical vibrations or intense agitation can cause instability in certain level instruments, leading to erratic readings.

Interface Level: Measuring the point where two immiscible liquids meet (e.g., oil and water) requires technology that can distinguish between the different properties (like density or dielectric constant) of the two fluids.

Overview of Level Measurement Technologies ⚙️

Numerous level measurement technologies are available, each with its own advantages and limitations. Here’s an overview of the key players:

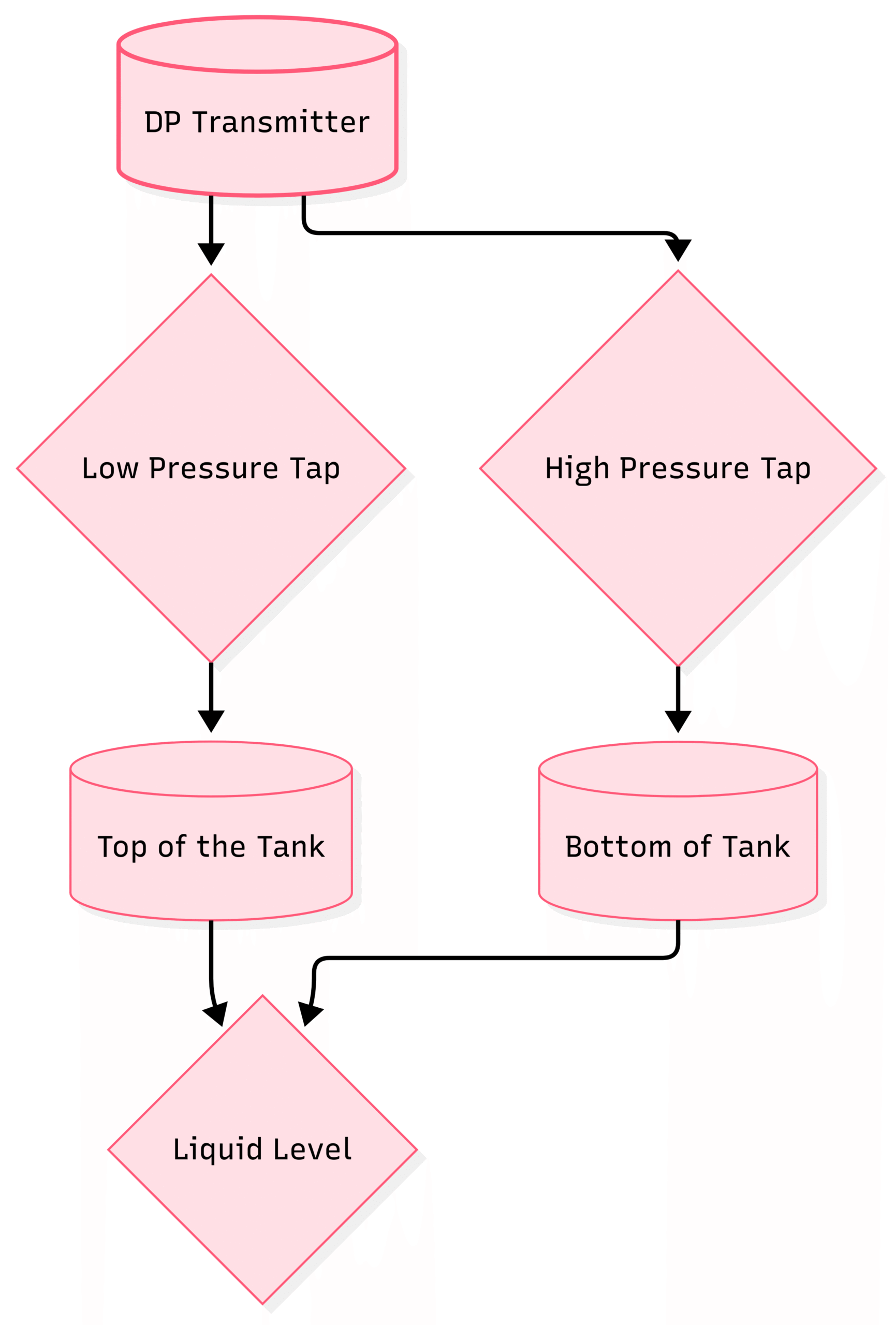

Differential Pressure (DP) Transmitters: These instruments measure the pressure difference between two points, typically the top and bottom of a tank. This pressure difference is proportional to the liquid level, assuming a constant density.

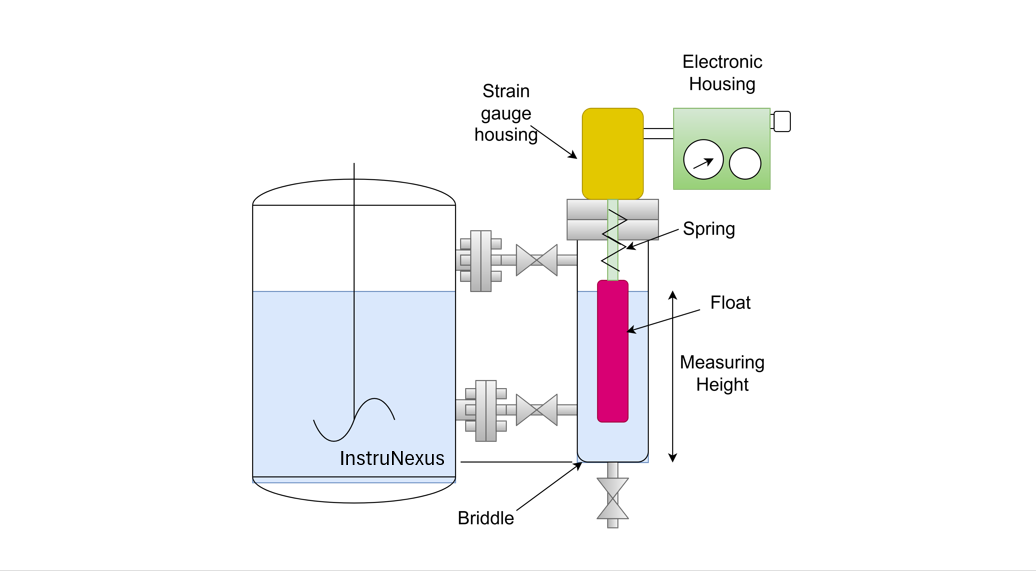

Displacer Level Transmitters: A displacer element (a weighted cylinder) is suspended in the process fluid. Based on Archimedes’ principle, the buoyant force exerted on the displacer is proportional to the amount of liquid it displaces. This force change is measured by a torque tube and converted into a level measurement. They are excellent for both total level and interface level.

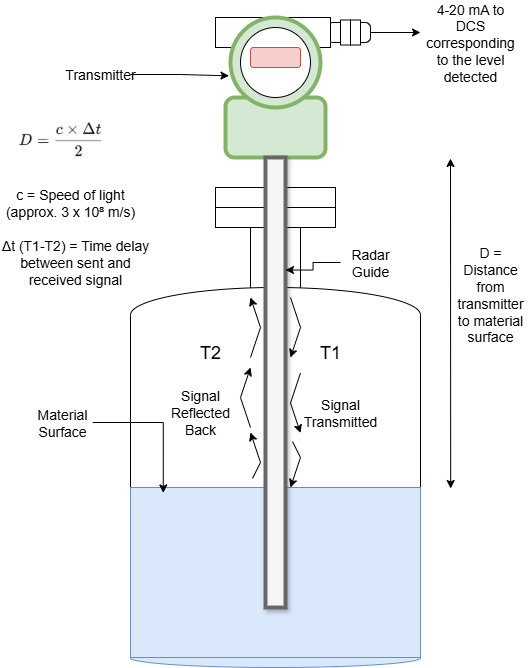

Radar (Guided Wave and Non-Contact): Radar level transmitters emit electromagnetic waves and measure the time it takes for the reflected waves to return from the surface.

Guided Wave Radar (GWR): The waves are guided along a probe or cable, making it highly reliable and less susceptible to atmospheric conditions, foam, or turbulence. It’s also a top choice for interface level.

Non-Contact Radar (Free Space Radar): The waves are transmitted through the air towards the liquid or solid surface.

Ultrasonic Level Transmitters: These non-contact instruments emit high-frequency sound waves and measure the time it takes for the echoes to return from the material surface.

Capacitance Level Transmitters: These sensors measure the change in capacitance between a probe and the tank wall as the liquid level changes. The principle relies on the difference in dielectric constants between the process material and the vapor space.

Magnetostrictive Level Transmitters: These instruments use a float containing a magnet that moves along a probe. The interaction between the float’s magnet and an electrical pulse sent down the probe creates a return signal, precisely indicating the float’s position.

Radiometric Level Transmitters (Gamma Rays): These non-contact systems use a radioactive source and a detector mounted on opposite sides of the vessel. The material in the vessel absorbs the gamma rays, and the amount of radiation reaching the detector is inversely proportional to the level.

Selecting the Right Instrument for Specific Challenges 🤔

Now, let’s analyze how different level measurement technologies fare under specific challenging process conditions.

1. Extreme Temperatures

High Temperatures:

Best Choices: Differential Pressure (DP) with remote seals and capillary tubing to isolate electronics; Displacer transmitters with cooling fins; Guided Wave Radar (GWR) and Non-Contact Radar with high-temperature probes/antennas; Radiometric systems are entirely external and unaffected.

Considerations: Ensure all wetted parts and seals can withstand the process temperature. For DP and displacers, fluid density changes with temperature must be compensated for.

Less Suitable: Standard Ultrasonic, Capacitance, and Magnetostrictive instruments have strict temperature limits for their sensors and electronics.

Low Temperatures:

Best Choices: GWR and Non-Contact Radar are generally reliable. DP transmitters require freeze protection (heat tracing) for impulse lines.

Considerations: Beware of process fluid freezing in impulse lines or on probes. Ensure instrument materials remain ductile at cryogenic temperatures.

Less Suitable: Ultrasonic signal speed changes with air density at low temperatures.

2. High Pressures

Best Choices: DP transmitters are inherently designed for pressure measurement. Displacer transmitters are robust and well-suited for high-pressure applications. GWR and Non-Contact Radar with high-pressure rated process connections are also excellent. Radiometric systems are unaffected as they are external.

Considerations: Verify that the pressure rating of the instrument, including flanges and seals, exceeds the maximum process pressure.

Less Suitable: Ultrasonic performance can be altered by high-pressure gas density. Standard Magnetostrictive and Float instruments require specialized high-pressure designs.

3. Corrosive Substances

Best Choices: Non-contact technologies like Radar and Ultrasonic are ideal. For contact instruments, material selection is key. DP transmitters with diaphragm seals made of compatible materials (e.g., Hastelloy, Tantalum), GWR with coated or alloy probes, and Capacitance probes with PTFE coatings are good options. Radiometric systems are immune as they don’t touch the process fluid.

Considerations: Analyze the complete chemical profile to select the right corrosion-resistant materials for all wetted parts.

Less Suitable: Standard stainless steel components in Displacer or Magnetostrictive transmitters may fail quickly if not specified correctly for the corrosive media.

4. Viscous Materials & Coating

Best Choices: Non-Contact Radar is often a great choice if buildup isn’t excessive. DP transmitters with large-diameter remote seals can prevent clogging. Radiometric systems are unaffected. Displacer transmitters can often handle some coating due to the large buoyant force.

Considerations: For GWR, a single-lead probe design is less prone to bridging than twin or coaxial designs. For contact technologies, periodic cleaning may still be necessary.

Less Suitable: Ultrasonic signals are easily dampened by thick, viscous materials. Capacitance probes are highly susceptible to errors from conductive coatings. Magnetostrictive floats can get stuck.

5. Foaming or Turbulent Surfaces

Best Choices: Guided Wave Radar (GWR) is the standout choice, as its guided pulse ignores foam and provides a stable reading from the true liquid surface. Non-Contact Radar with advanced signal processing can filter out surface noise. Displacers and DP systems naturally provide an averaged, more stable reading in turbulent conditions. Radiometric systems measure bulk level and are unaffected by surface conditions.

Considerations: Stilling wells can be used to shield instruments like Magnetostrictive floats or Displacers from severe turbulence.

Less Suitable: Ultrasonic signals are easily absorbed or scattered by foam and turbulence, making them highly unreliable in these applications.

6. Solids and Slurries

Best Choices: Non-Contact Radar, especially low-frequency (e.g., ~24 GHz) models, is preferred for its ability to penetrate dust and handle the angle of repose of solids. Radiometric systems are highly effective and non-intrusive. Ultrasonic can work for some applications but is very sensitive to dust.

Considerations: For slurries with a distinct liquid surface, higher-frequency radar might provide better resolution.

Less Suitable: DP, Displacer, Capacitance, and Magnetostrictive instruments are generally unsuitable for solids due to clogging, abrasion, and bridging. GWR can be used in some slurries but risks probe damage and burial.

7. Interface Level Measurement

Best Choices: Guided Wave Radar (GWR) is a leading technology for interface detection. The radar pulse reflects off both the upper product surface and the interface, allowing for measurement of both. Displacer transmitters are a classic and highly reliable choice, designed to sink through the upper liquid and float on the heavier lower liquid. Capacitance probes can also work if the two liquids have a significant and consistent difference in their dielectric constants.

Considerations: For GWR and Capacitance, a sufficient difference in dielectric constants between the two liquids is required. For Displacers, the displacer element must be sized based on the specific gravities of both liquids, and there must be a sufficient density difference.

Less Suitable: Non-Contact Radar, Ultrasonic, and standard DP transmitters can only see the top surface and cannot detect an interface. Radiometric systems can be configured for interface but are often complex and expensive for this specific task.

A Structured Approach to Instrument Selection 🛠️

Selecting the optimal level instrument for challenging process conditions requires a systematic approach:

Thorough Process Analysis: Clearly define all relevant process parameters, including temperature, pressure, fluid properties (viscosity, density, corrosiveness, dielectric constant), presence of foam, turbulence, solids, dust, and whether an interface level is required.

Identify Potential Challenges: Based on the analysis, pinpoint the specific challenges that will impact level measurement.

Evaluate Technology Suitability: For each challenge, assess the suitability of different technologies using the guide above. Create a shortlist of potential candidates.

Consider Application-Specific Requirements: Factor in accuracy needs, measurement range, output signals, safety certifications (e.g., SIL), and control system integration.

Assess Installation and Maintenance: Evaluate the ease of installation, calibration, and long-term maintenance for each potential instrument.

Review Total Cost of Ownership: Consider the initial purchase price, installation costs, maintenance requirements, and expected lifespan. A cheaper instrument that fails frequently is more expensive in the long run.

Consult with Experts: Engage with experienced instrumentation engineers and manufacturer representatives. Provide them with your detailed process data to get their expert recommendations.

Final Selection and Documentation: Make the final instrument selection based on a comprehensive evaluation. Document the decision-making process, including why the chosen technology is best suited for the application and any specific operational considerations.

Conclusion 🎯

Selecting level instruments for challenging process conditions is a critical engineering task that goes far beyond a simple catalog selection. By thoroughly understanding the specific process challenges—be it extreme temperatures, high pressures, corrosive media, or complex interfaces—and by systematically evaluating the capabilities of modern technologies like Guided Wave Radar, Displacers, and Differential Pressure systems, you can ensure accurate, reliable, and safe level measurement. Choosing the right instrument is a direct investment in the efficiency, safety, and profitability of your operations.