IEC 61508 Overview: The Foundation of Functional Safety Standards

In our increasingly automated world, the silent sentinels of safety are often complex electronic systems. From the emergency shutdown systems in a chemical plant to the braking control in a modern vehicle, these systems are the invisible guardians that prevent catastrophic failures. But how do we ensure these guardians are themselves reliable? The answer lies in the robust framework of functional safety, and at its very core is the international standard IEC 61508. This seminal document, often referred to as the “mother” of all functional safety standards, provides a comprehensive methodology for the entire lifecycle of safety-related systems, ensuring they perform their intended function correctly or fail in a predictable and safe manner.

This blog post will provide a comprehensive 2000-word overview of IEC 61508, exploring its history, fundamental principles, the critical concept of the safety lifecycle, the risk-based approach of Safety Integrity Levels (SILs), and its pervasive influence on industry-specific safety standards.

A Look Back: The Genesis of IEC 61508

The late 20th century saw a rapid increase in the use of electrical, electronic, and programmable electronic (E/E/PE) systems in safety-critical applications. While these technologies offered significant advantages in terms of performance and flexibility, they also introduced new and complex failure modes that were not adequately addressed by traditional safety engineering approaches. Incidents in various industries highlighted the need for a standardized approach to designing, implementing, and maintaining these safety systems.

In response to this growing concern, the International Electrotechnical Commission (IEC) initiated the development of a generic functional safety standard in the mid-1980s. The goal was to create a comprehensive framework that could be applied across different industries, providing a common language and a consistent set of requirements for ensuring the safety of E/E/PE systems. After years of international collaboration and expert input, the first edition of IEC 61508 was published in parts between 1998 and 2000. A second edition, which further refined and clarified the requirements, was released in 2010.

The Core Principles: Building a Framework for Safety

IEC 61508 is built upon a set of fundamental principles that guide the entire process of achieving functional safety. These principles are not merely suggestions but form the bedrock of the standard’s rigorous approach.

The Safety Lifecycle: The cornerstone of IEC 61508 is the concept of the safety lifecycle. This is a structured engineering process that encompasses all activities involved in the life of a safety-related system, from initial concept and hazard analysis to design, installation, operation, maintenance, and eventual decommissioning. By following a defined lifecycle, organizations can ensure that safety is considered at every stage and that all necessary activities are systematically planned, executed, and documented.

Hazard and Risk Assessment: A key tenet of the standard is a proactive approach to safety. This begins with a thorough hazard and risk assessment. The goal is to identify all potential hazards associated with the equipment under control (EUC) and its control system. Once hazards are identified, their associated risks are analyzed to determine if they are tolerable. If the risks are deemed unacceptable, risk reduction measures must be implemented.

Risk-Based Approach and ALARP: IEC 61508 champions a risk-based approach, where the level of rigor and effort required to demonstrate safety is proportional to the level of risk. The principle of “As Low As Reasonably Practicable” (ALARP) is central to this. It requires that risks are reduced to a level that is considered tolerable, taking into account both the technical feasibility and the cost of further risk reduction.

Performance-Based, Not Prescriptive: Unlike some traditional safety standards that prescribe specific technologies or design solutions, IEC 61508 is performance-based. It specifies what needs to be achieved in terms of safety performance, but it does not dictate how it should be achieved. This flexibility allows for innovation and the adoption of new technologies while still ensuring the required level of safety.

Quantification of Safety Performance: A groundbreaking aspect of IEC 61508 is its emphasis on quantifying safety performance. This is achieved through the concept of Safety Integrity Levels (SILs), which we will explore in detail later. By assigning a probabilistic measure to the performance of safety functions, the standard provides a clear and objective way to specify and verify the required level of risk reduction.

The IEC 61508 Safety Lifecycle: A Step-by-Step Journey to Safety

The safety lifecycle is a systematic and documented process that ensures functional safety is an integral part of the entire lifespan of a safety-related system. While the standard provides a reference lifecycle with 16 distinct phases, the underlying principle is a continuous cycle of analysis, realization, and operation.

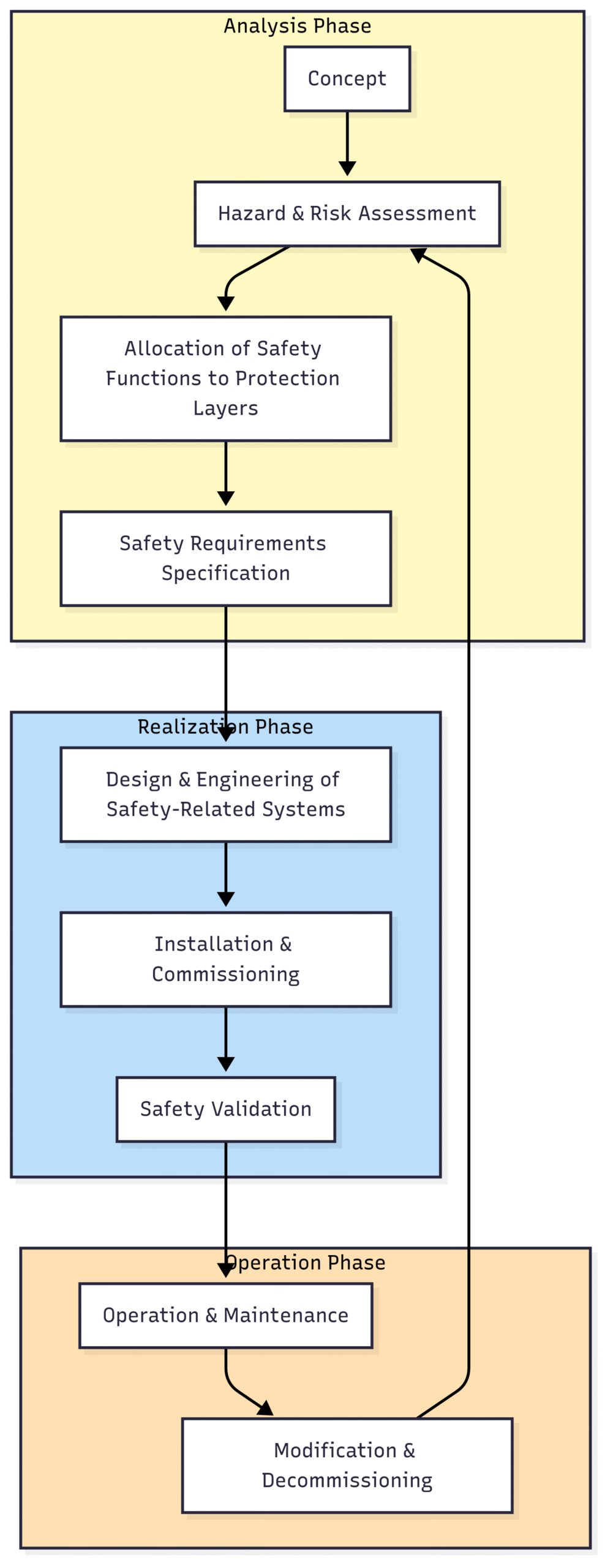

A Simplified Block Diagram of the IEC 61508 Safety Lifecycle:

The key phases of the safety lifecycle can be broadly categorized as:

Analysis Phase: This initial phase focuses on understanding the system and its potential hazards. It involves:

Concept Definition: Defining the scope and boundaries of the equipment under control (EUC) and its control system.

Hazard and Risk Analysis: A systematic process to identify potential hazards, their causes, and their consequences. Techniques like HAZOP (Hazard and Operability Study) and FMEA (Failure Modes and Effects Analysis) are often employed.

Allocation of Safety Functions: Determining the necessary risk reduction and allocating safety functions to different protection layers, including the safety-related systems.

Safety Requirements Specification: This is a critical document that details the requirements for each safety function, including its intended function, the required SIL, and any timing or environmental constraints.

Realization Phase: This phase involves the design, development, and implementation of the safety-related systems. It includes:

Design and Engineering: Designing the hardware and software of the safety-related system to meet the specified safety requirements. This includes selecting appropriate components, designing for fault tolerance, and implementing diagnostic features.

Installation and Commissioning: The physical installation and testing of the safety-related system to ensure it is correctly installed and integrated with the EUC.

Safety Validation: A thorough process to demonstrate that the implemented safety-related system meets the requirements of the safety requirements specification and the specified SIL. This involves extensive testing and analysis.

Operation and Maintenance Phase: This is the longest phase of the lifecycle and focuses on maintaining the integrity of the safety-related system throughout its operational life. It encompasses:

Operation: Ensuring the system is operated within its design limits.

Maintenance and Repair: Performing regular maintenance activities, including proof testing, to detect and correct any potential failures.

Modification: A managed process for making any changes to the safety-related system, ensuring that the impact of the changes on safety is properly assessed.

Decommissioning: The final phase of the lifecycle, which involves the safe removal of the safety-related system from service.

Safety Integrity Level (SIL): Quantifying the Confidence in Safety

One of the most significant contributions of IEC 61508 is the concept of Safety Integrity Level (SIL). A SIL is a discrete level (from 1 to 4) that represents the required level of risk reduction provided by a safety function. The higher the SIL, the greater the required risk reduction and the lower the probability that the safety function will fail on demand.

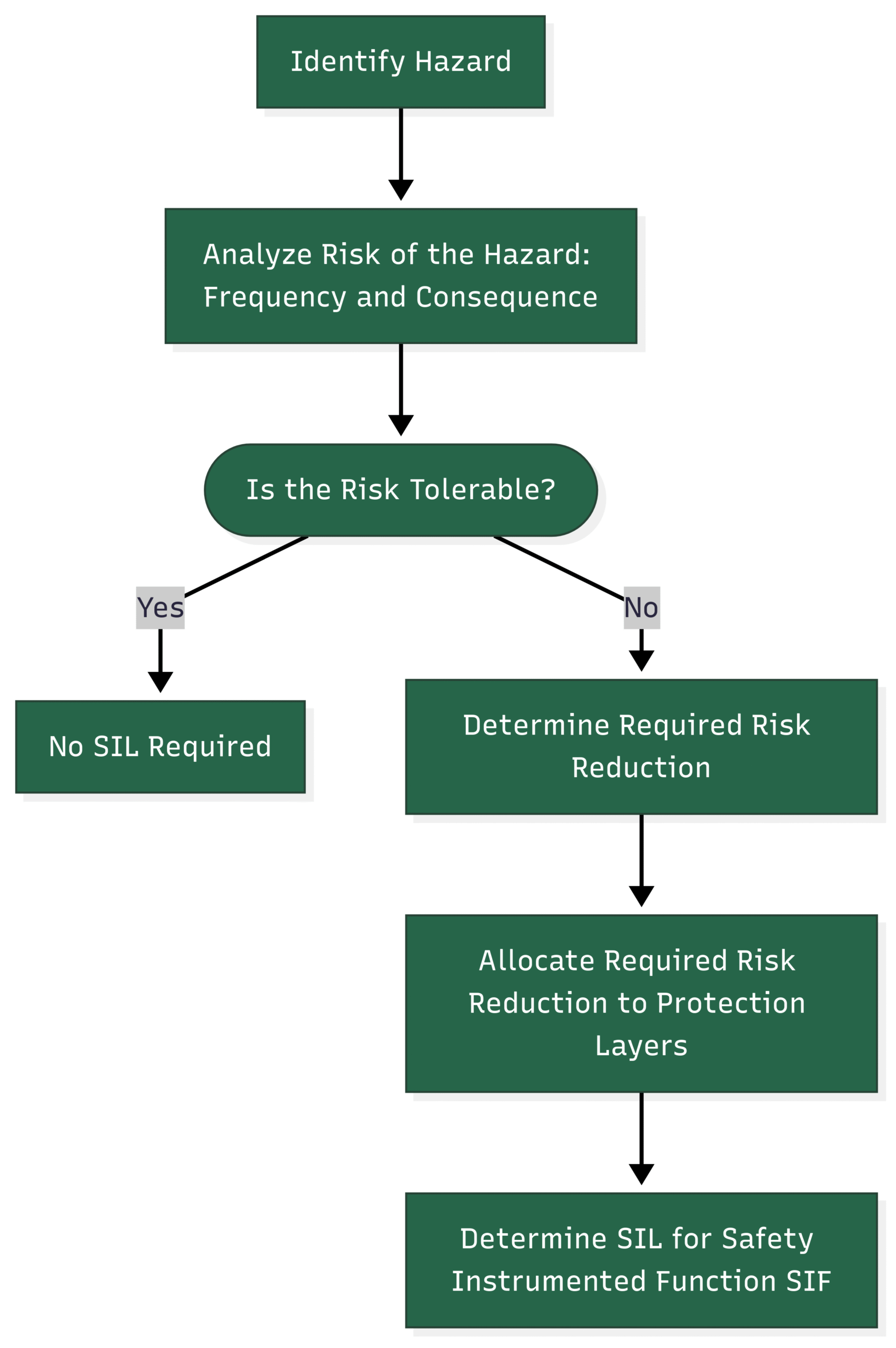

The SIL Determination Process:

The determination of the required SIL for a safety function is a critical step in the safety lifecycle and is based on the results of the hazard and risk analysis. In simple terms, the higher the unmitigated risk, the higher the required SIL.

A Simplified Block Diagram of the SIL Determination Process:

The SIL of a safety function is determined by three key factors:

Hardware Safety Integrity (Probability of Dangerous Failure): This is a quantitative measure of the reliability of the hardware components of the safety system. It is expressed as the Probability of Failure on Demand (PFD) for low-demand mode systems or the Probability of Dangerous Failure per Hour (PFH) for high-demand or continuous mode systems.

SIL | PFD (Low Demand Mode) | PFH (High/Continuous Demand Mode) |

4 | ≥10⁻⁵ to <10⁻⁴ | ≥10⁻⁹ to <10⁻⁸ |

3 | ≥10⁻⁴ to <10⁻³ | ≥10⁻⁸ to <10⁻⁷ |

2 | ≥10⁻³ to <10⁻² | ≥10⁻⁷ to <10⁻⁶ |

1 | ≥10⁻² to <10⁻¹ | ≥10⁻⁶ to <10⁻⁵ |

Architectural Constraints: IEC 61508 places constraints on the architecture of the safety system based on the required SIL. These constraints often mandate the use of redundancy (e.g., multiple channels) to tolerate hardware faults. The required Hardware Fault Tolerance (HFT) depends on the SIL and the type of components used.

Systematic Capability (SC): This relates to the prevention of systematic failures, which are failures introduced during the design, implementation, or maintenance of the system (e.g., software bugs, incorrect specifications). Achieving a certain SIL requires demonstrating a corresponding level of systematic capability, which is achieved by following rigorous development processes, using appropriate tools and techniques, and having competent personnel.

The Seven Parts of IEC 61508: A Detailed Breakdown

IEC 61508 is a comprehensive standard consisting of seven parts, each addressing a specific aspect of functional safety:

Part 1: General requirements: Provides the overall framework for the standard, including the safety lifecycle, management of functional safety, and the requirements for documentation.

Part 2: Requirements for E/E/PE safety-related systems: Specifies the requirements for the hardware of the safety-related system, including hardware design, testing, and management of hardware modifications.

Part 3: Software requirements: Details the requirements for the software used in safety-related systems, covering the entire software development lifecycle from requirements specification to testing and maintenance.

Part 4: Definitions and abbreviations: Provides a glossary of terms and abbreviations used throughout the standard.

Part 5: Examples of methods for the determination of safety integrity levels: Offers guidance and examples on how to determine the required SIL for a safety function.

Part 6: Guidelines on the application of IEC 61508-2 and IEC 61508-3: Provides practical guidance on implementing the hardware and software requirements of the standard.

Part 7: Overview of techniques and measures: Presents a variety of techniques and measures that can be used to meet the requirements of the standard, such as different types of analysis and testing methods.

The Umbrella Standard: IEC 61508’s Influence on Industry-Specific Standards

While IEC 61508 is a generic standard applicable to any industry, its true power lies in its role as an “umbrella” or “basic safety publication.” It provides the fundamental principles and requirements that are then adapted and tailored to the specific needs of different sectors. This has led to the development of a family of industry-specific functional safety standards that are based on IEC 61508.

Some of the key sector-specific standards derived from IEC 61508 include:

IEC 61511 (Process Industry): This standard provides guidance on the application of functional safety in the process industry, such as chemical plants, oil and gas refineries, and pharmaceutical manufacturing.

ISO 26262 (Automotive): This standard adapts the principles of IEC 61508 for the automotive industry, addressing the unique challenges of safety-related electronic systems in vehicles.

IEC 62061 (Machinery): This standard focuses on the application of functional safety to the control systems of machinery.

EN 50126/50128/50129 (Railway): This set of standards applies the principles of functional safety to the railway industry, covering the entire system lifecycle for railway applications.

IEC 61513 (Nuclear): This standard provides specific requirements for instrumentation and control systems important to safety in nuclear power plants.

By providing a common foundation, IEC 61508 ensures a consistent approach to functional safety across these diverse industries, promoting interoperability and facilitating the exchange of best practices.

Real-World Application: Where IEC 61508 Makes a Difference

The impact of IEC 61508 is felt across a wide range of industries where safety is paramount. Here are a few examples:

Process Industries: In a chemical plant, a safety instrumented system (SIS) designed according to IEC 61511 (and therefore IEC 61508) might be responsible for shutting down a reactor in the event of a high-temperature or high-pressure excursion, preventing a potential explosion.

Automotive: The airbag deployment system in a car is a safety-critical function. The electronic control unit (ECU) that controls the airbag is developed in accordance with ISO 26262, ensuring it reliably deploys the airbag when needed and avoids spurious deployments.

Manufacturing: In a factory with robotic arms, a safety system compliant with IEC 62061 would ensure that the robot stops immediately if a worker enters a hazardous area, preventing serious injuries.

Renewable Energy: Wind turbines are equipped with safety systems to prevent overspeed and other hazardous conditions. These systems are designed and certified to meet the requirements of IEC 61508 to ensure their reliability.

Conclusion: The Enduring Legacy of IEC 61508

In a world increasingly reliant on complex technology, the need for a robust and systematic approach to safety has never been greater. IEC 61508 provides that essential framework. It has revolutionized the way we think about and manage the safety of electronic systems, moving from a reactive, incident-driven approach to a proactive, lifecycle-based methodology.

Its principles of a structured safety lifecycle, rigorous hazard and risk analysis, and the quantitative measure of SILs have become the global benchmark for functional safety. As technology continues to evolve, with the rise of artificial intelligence and the Internet of Things, the principles enshrined in IEC 61508 will undoubtedly continue to be the cornerstone of ensuring that our technological advancements are not only innovative but also fundamentally safe. For any engineer, manager, or organization involved in the development or use of safety-critical systems, a thorough understanding of IEC 61508 is not just beneficial; it is essential. It is the language of safety in our modern, automated world.