Laminar vs. Turbulent Flow

An In-Depth Guide for Instrumentation Students

In the world of fluid dynamics, understanding the difference between laminar and turbulent flow is essential for instrumentation engineers, particularly those working in the oil, gas, and chemical industries. Flow types influence the performance of various instruments, such as flow meters, pressure gauges, and level transmitters. In this blog, we’ll explore the key concepts of laminar and turbulent flow, the factors that determine flow types, and the implications for instrumentation students. This knowledge forms the foundation for various applications, including process control, measurement, and troubleshooting.

1. What is Laminar Flow?

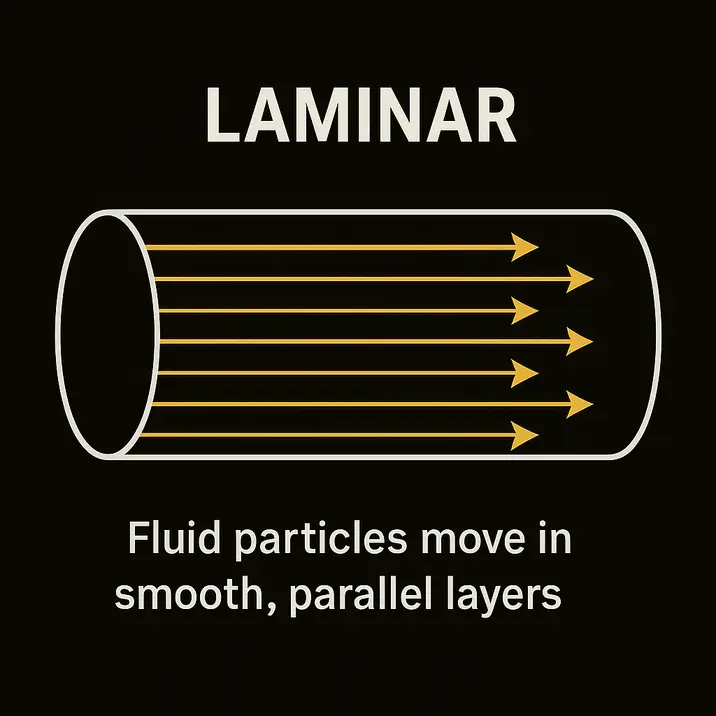

Laminar flow (from the Latin *lamina*, meaning thin plate or layer) occurs when a fluid flows in smooth, parallel layers with minimal mixing. Imagine cards in a deck sliding past one another; each layer of fluid moves in the same direction, with adjacent layers sliding smoothly. The flow velocity is typically low, and the fluid moves steadily without eddies or swirls. This predictable, orderly state is often seen in small diameter pipes or with highly viscous fluids at low velocities.

Key Characteristics:

- Smooth and Steady: The flow is orderly with no cross-currents or swirls.

- Low Velocity: Occurs at lower velocities where viscous forces (the "stickiness" of the fluid) dominate over inertial forces (the fluid's tendency to keep moving).

- Predictable Behavior: Fluid particles move in well-defined paths, making it easy to model mathematically.

2. What is Turbulent Flow?

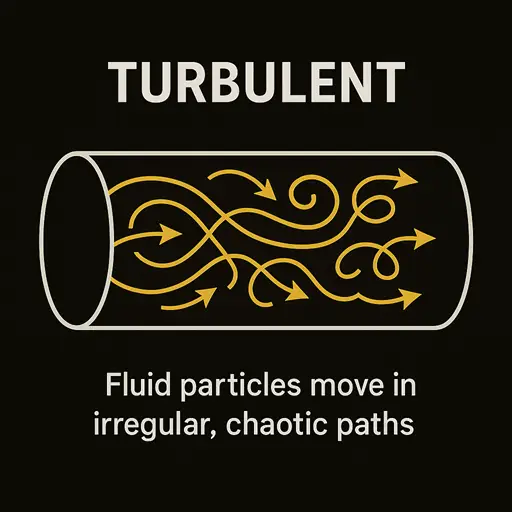

Turbulent flow is the chaotic, unsteady, and unpredictable counterpart to laminar flow. It's characterized by eddies, swirls, and vortices that lead to significant mixing within the fluid. This occurs when inertial forces overwhelm viscous forces, typically at higher velocities or in larger pipes. This chaotic motion results in higher frictional resistance and greater energy loss compared to laminar flow.

Key Characteristics:

- Chaotic and Unsteady: The flow is erratic, with fluid particles moving randomly.

- High Velocity: Occurs at higher velocities where the fluid's inertia overcomes its viscosity.

- Enhanced Mixing & Energy Loss: The swirling motion promotes mixing but also dissipates significant energy as heat due to friction.

3. Interactive Reynolds Number Calculator

The transition between flow types is predicted by the Reynolds number (Re), a dimensionless quantity. Use the calculator below to see how different parameters affect the flow regime.

Re = (ρ · v · d) / μ

Calculated Reynolds Number:

50,000

Typical water values at room temperature are used as defaults.

4. Critical Implications for Instrumentation

The flow regime fundamentally impacts instrument selection, installation, and accuracy. An engineer must account for these differences to ensure reliable process control.

Flow Meter Selection

No single flow meter works for all conditions. For laminar flow, meters like positive displacement or laminar flow elements excel. For turbulent flow, technologies like vortex, ultrasonic, or turbine meters are required. Using the wrong meter can lead to significant measurement errors.

Installation Requirements

Turbulent flow profiles can be distorted by bends, valves, or pumps. This requires installing flow meters with sufficient straight pipe runs upstream and downstream to allow the flow to stabilize, a critical consideration for accuracy.

Pressure Measurement and Control

Turbulent flow causes a much higher pressure drop due to friction. Pressure transmitters and control valves must be sized correctly to handle this. Miscalculations can lead to inefficient pumping, energy waste, or even process failure.

5. Advanced Topics for Further Reading

Boundary Layer: The thin layer of fluid near the pipe wall where viscous effects are dominant. In turbulent flow, there's still a very thin laminar sub-layer right at the wall.

Flow Profiling: The velocity of the fluid is not uniform across the pipe. Laminar flow has a parabolic profile (fastest at the center), while turbulent flow has a flatter, more "plug-like" profile.

Computational Fluid Dynamics (CFD): Powerful software tools used to simulate fluid flow, helping engineers design systems and predict how laminar or turbulent conditions will behave without physical prototypes.

6. Knowledge Check Quiz

1. Which flow type is characterized by smooth, parallel layers?

2. A high Reynolds number (e.g., > 10,000) typically indicates:

3. Which factor is NOT part of the Reynolds number calculation?

Introduction:

In the world of fluid dynamics, understanding the difference between laminar and turbulent flow is essential for instrumentation engineers, particularly those working in the oil, gas, and chemical industries. Flow types influence the performance of various instruments, such as flow meters, pressure gauges, and level transmitters. In this blog, we’ll explore the key concepts of laminar and turbulent flow, the factors that determine flow types, and the implications for instrumentation students. This knowledge forms the foundation for various applications, including process control, measurement, and troubleshooting.

1. What is Laminar Flow?

Laminar flow occurs when a fluid flows in smooth, parallel layers with minimal mixing. Each layer of fluid moves in the same direction, with adjacent layers sliding over each other. The flow velocity is typically low, and the fluid moves steadily without eddies or swirls. Laminar flow is typically seen in small diameter pipes or with low-flow velocities.

Characteristics of Laminar Flow:

-

Smooth and Steady: The flow is smooth, and there is little to no turbulence.

-

Low Velocity: Laminar flow usually occurs at lower velocities where friction forces dominate over inertial forces.

-

Predictable Behavior: The fluid particles move in a predictable manner, making it easier to model mathematically.

Applications of Laminar Flow:

-

Microfluidic Systems: Laminar flow is often used in systems where precise fluid control is required, such as in medical devices or laboratory instruments.

-

Viscosity Measurements: Laminar flow is essential in the measurement of the viscosity of fluids, as it provides a consistent environment for testing.

2. What is Turbulent Flow?

Turbulent flow, in contrast to laminar flow, occurs when the fluid moves chaotically with eddies, swirls, and vortices. This type of flow is characterized by high velocity and irregular fluid motion. Turbulence is common in larger pipes or when fluids are flowing at high speeds. This type of flow is difficult to predict and often results in a higher frictional resistance compared to laminar flow.

Characteristics of Turbulent Flow:

-

Chaotic and Unsteady: The flow is erratic, with fluid particles moving in random directions.

-

High Velocity: Turbulent flow occurs at higher velocities where inertial forces dominate over viscous forces.

-

Energy Loss: Turbulent flow leads to higher energy losses due to friction and turbulence.

Applications of Turbulent Flow:

-

Industrial Process Systems: Many industrial systems, such as pipelines for oil and gas, operate under turbulent flow conditions, which must be considered when designing measurement and control systems.

-

Flow Meters: Turbulent flow is often associated with specific types of flow meters, such as vortex flow meters, which can handle high-velocity flow conditions.

3. Transition from Laminar to Turbulent Flow

The transition between laminar and turbulent flow is not always abrupt. Instead, it occurs gradually over a range of fluid velocities, and the flow can become unstable as the velocity increases. This transition is described by the Reynolds number (Re), which is a dimensionless quantity that helps predict the flow regime in a given system.

Reynolds Number and Flow Regimes:

-

Reynolds Number (Re): The Reynolds number is calculated as:

Re=ρ⋅v⋅d/μ

Where:

-

ρ\rhoρ is the fluid density

-

v is the velocity of the fluid

-

d is the characteristic length (typically the diameter of the pipe)

-

μ\muμ is the dynamic viscosity of the fluid

-

-

Laminar Flow: When the Reynolds number is below approximately 2,000, the flow remains laminar.

-

Turbulent Flow: For Reynolds numbers greater than 4,000, the flow is generally turbulent.

-

Transitional Flow: In the range between 2,000 and 4,000, the flow can transition from laminar to turbulent, exhibiting both characteristics.

4. Key Differences Between Laminar and Turbulent Flow

To better understand the distinction between laminar and turbulent flow, here’s a breakdown of key differences:

| Property | Laminar Flow | Turbulent Flow |

|---|---|---|

| Flow Behavior | Smooth and orderly | Chaotic and irregular |

| Velocity Profile | Parabolic, with maximum velocity at the center of the pipe | Flatter profile with velocity variations across the pipe diameter |

| Flow Regime | Occurs at lower velocities | Occurs at higher velocities |

| Reynolds Number | Below 2,000 | Above 4,000 |

| Energy Loss | Low energy loss | High energy loss due to friction |

| Measurement Methods | Can be accurately measured using laminar flow meters | Requires special flow meters such as vortex or ultrasonic flow meters |

| Applications | Medical devices, microfluidics | Industrial applications, large pipelines |

5. Implications for Instrumentation Students

For instrumentation students, understanding the differences between laminar and turbulent flow is crucial, as it affects the selection, installation, and performance of various measuring instruments. Here’s how these flow types impact instrumentation in practical scenarios:

Flow Meter Selection:

Different flow meters perform better under different flow conditions. Students must understand these principles to choose the right type of flow meter for a given application.

-

Laminar Flow Meters: These are designed for low-velocity applications and are ideal for precise measurements, such as in medical or laboratory environments.

-

Turbulent Flow Meters: These are designed to handle high-velocity flows and are commonly used in industrial applications. Vortex and ultrasonic flow meters are designed to work effectively in turbulent flow conditions.

Pressure and Temperature Measurement:

Flow types also influence pressure drop and temperature variations within pipelines. Instruments such as pressure gauges and temperature transmitters must be calibrated with respect to the flow conditions, as turbulent flow can cause additional pressure drops due to friction and vortex formation.

Flow Control:

In industrial applications, controlling flow rates becomes more complex in turbulent flow conditions. Instrumentation students need to understand how control valves and actuators function differently in turbulent systems to ensure proper system operation.

Process Optimization:

Students should also be aware that turbulent flow can lead to issues such as excessive energy consumption due to friction losses. Optimizing the flow to maintain laminar conditions in specific parts of the system can reduce operational costs.

6. Challenges in Measuring Turbulent Flow

Turbulent flow presents several challenges for instrumentation engineers, including:

-

Increased Noise: Turbulent flow can introduce noise in flow measurements, which affects the accuracy of flow meters.

-

Higher Frictional Losses: The chaotic nature of turbulent flow leads to greater energy losses, which can affect pressure measurements.

-

Flow Profile Distortions: In large systems, the flow profile can become highly uneven, complicating the interpretation of flow data.

Instrumentation students must learn to account for these factors when selecting instruments for turbulent flow environments.

7. Practical Tips for Instrumentation Engineers

Here are a few practical tips for instrumentation engineers working with laminar and turbulent flow systems:

-

Regular Calibration: Regularly calibrate flow meters and other instruments to ensure they remain accurate under varying flow conditions.

-

Understand Flow Characteristics: Know when the flow in a system transitions from laminar to turbulent, as this can impact measurement accuracy and system performance.

-

Use Appropriate Flow Meters: Select flow meters based on the flow regime (laminar or turbulent) to ensure optimal measurement accuracy and reliability.

-

Account for Pressure Drops: Be aware of the pressure drops associated with turbulent flow, which can affect system performance and efficiency.

Conclusion

Understanding the difference between laminar and turbulent flow is a fundamental concept that every instrumentation student must master. This knowledge influences not only the selection and use of measurement instruments but also the design and optimization of industrial systems. As an instrumentation engineer, being able to assess flow conditions and apply the appropriate technology is key to ensuring accurate and efficient system operations.

By recognizing the characteristics of laminar and turbulent flow, students can enhance their expertise in fluid dynamics and its applications in instrumentation.