Understanding the Fundamentals: What are Flow Meters and Why are They Crucial?

Before we delve into the specifics of magnetic and differential pressure flow meters, let’s establish a foundational understanding. A flow meter is a device engineered to measure the volume or mass of a gas or liquid. The “flow” in flow rate refers to the speed at which a fluid is moving through a conduit, typically measured in units like liters per minute (LPM), gallons per minute (GPM), or cubic meters per hour (m³/h).

The importance of accurate flow measurement cannot be overstated. In a chemical plant, precise flow control is essential for ensuring reactions proceed as planned. In a water treatment facility, it’s vital for monitoring consumption and ensuring proper dosage of treatment chemicals. In the oil and gas industry, custody transfer applications demand the highest accuracy for billing and inventory management. An incorrect flow reading can lead to production inefficiencies, product quality issues, safety hazards, and significant financial losses.

The Magnetic Flow Meter: Harnessing the Power of Electromagnetism

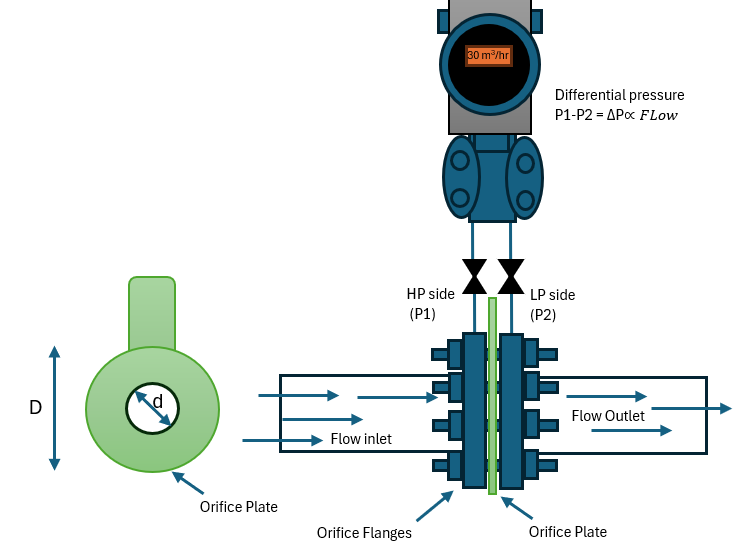

A magnetic flow meter, often referred to as a mag meter, operates on a principle that sounds like it’s straight out of a physics textbook: Faraday’s Law of Electromagnetic Induction. This law states that a voltage is induced in a conductor moving through a magnetic field. In the context of a mag meter, the conductive fluid itself acts as the conductor.

Operating Principle of a Magnetic Flow Meter

At the heart of a magnetic flow meter are a pair of electromagnetic coils and a pair of electrodes. When the meter is energized, the coils generate a magnetic field perpendicular to the direction of the fluid flow. As the conductive fluid passes through this magnetic field, a voltage is induced that is directly proportional to the velocity of the fluid. This voltage is detected by the electrodes, which are positioned on opposite sides of the pipe, in contact with the fluid. The transmitter then processes this voltage signal and converts it into a flow rate measurement.

Block Diagram of a Magnetic Flow Meter:

Advantages of Magnetic Flow Meters:

- High Accuracy: Mag meters are renowned for their high accuracy, typically in the range of ±0.5% of the reading, and in some cases, even better. This makes them suitable for applications where precision is critical.

- No Moving Parts: The absence of any moving components in the flow stream means there is no mechanical wear and tear. This translates to minimal maintenance requirements and a long operational lifespan.

- Negligible Pressure Drop: Because there are no obstructions in the pipe, the pressure drop across a magnetic flow meter is virtually non-existent. This is a significant advantage in systems where maintaining pressure is crucial.

- Wide Turndown Ratio: Mag meters can accurately measure a wide range of flow rates, from very low to very high, offering excellent turndown ratios (the ratio of the maximum to the minimum measurable flow).

- Suitable for Slurries and Corrosive Fluids: The non-intrusive design and the availability of various liner materials make them ideal for measuring abrasive slurries, corrosive chemicals, and wastewater.

Disadvantages of Magnetic Flow Meters:

- Conductivity Requirement: The most significant limitation of magnetic flow meters is that they can only be used with conductive fluids. They are not suitable for measuring the flow of hydrocarbons, gases, demineralized water, or other non-conductive liquids. The fluid must have a minimum conductivity, typically around 5 microSiemens per centimeter (µS/cm).

- Cost: Generally, magnetic flow meters have a higher initial purchase cost compared to some other flow meter technologies, including differential pressure meters.

- Installation Considerations: Proper installation is crucial for accurate performance. This includes ensuring the pipe is full at all times and adhering to recommended upstream and downstream straight pipe lengths to avoid flow profile distortions.

- Susceptible to Electrical Noise: External electrical noise can sometimes interfere with the measurement, requiring proper grounding and shielding.

Typical Applications of Magnetic Flow Meters:

- Water and Wastewater Treatment

- Pulp and Paper Industry

- Mining and Mineral Processing

- Chemical and Pharmaceutical Industries

- Food and Beverage Production

- Power Generation

The Differential Pressure Flow Meter: A Time-Tested Principle of Fluid Dynamics

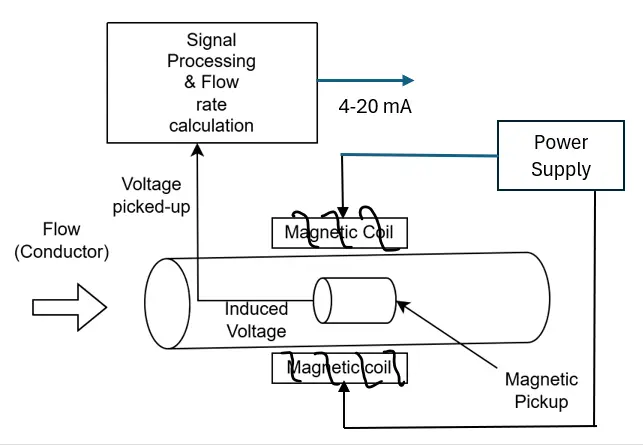

The differential pressure (DP) flow meter is one of the oldest and most widely used flow measurement technologies. Its operation is based on another fundamental principle of fluid dynamics: Bernoulli’s principle. This principle states that for an inviscid flow, an increase in the speed of the fluid occurs simultaneously with a decrease in pressure or a decrease in the fluid’s potential energy.

Operating Principle of a Differential Pressure Flow Meter

A DP flow meter works by introducing a precisely engineered constriction in the flow path. This constriction, known as a primary element, forces the fluid to accelerate as it passes through. According to Bernoulli’s principle, this increase in velocity results in a decrease in pressure. By measuring the pressure difference between the upstream (before the constriction) and the downstream (at or after the constriction) points, the flow rate can be calculated. The greater the pressure difference, the higher the flow rate.

Common types of primary elements used in DP flow meters include:

- Orifice Plates: A thin plate with a hole of a specific size.

- Venturi Tubes: A gradually converging and diverging tube.

- Flow Nozzles: A constricted passage with a smooth, elliptical inlet.

- Pitot Tubes: A tube that measures the difference between the total pressure and the static pressure.

Block Diagram of a Differential Pressure Flow Meter:

Advantages of Differential Pressure Flow Meters:

- Versatility: DP flow meters can be used to measure the flow of a wide variety of fluids, including liquids, gases, and steam.

- Cost-Effective: For larger pipe sizes, DP flow meters, particularly those using orifice plates, can be more cost-effective than magnetic flow meters.

- Well-Understood Technology: The principles behind DP flow measurement are well-established and understood, with a vast body of knowledge and standards available.

- High-Temperature and High-Pressure Applications: They can be designed to withstand extreme temperatures and pressures, making them suitable for demanding industrial environments.

Disadvantages of Differential Pressure Flow Meters:

- Permanent Pressure Loss: The constriction in the flow path inevitably leads to a permanent pressure loss in the system. This can result in increased energy consumption for pumping.

- Lower Accuracy and Turndown Ratio: The accuracy of DP flow meters is generally lower than that of magnetic flow meters, typically in the range of ±1% to ±2% of full scale. Their turndown ratio is also more limited.

- Susceptible to Wear and Clogging: The primary element is susceptible to erosion and corrosion, especially when measuring abrasive or corrosive fluids. It can also become clogged by particulate matter, leading to inaccurate readings and the need for regular maintenance.

- Installation Sensitivity: The accuracy of DP flow meters is highly sensitive to the installation conditions. They require long, straight runs of pipe both upstream and downstream of the meter to ensure a fully developed and undistorted flow profile.

- Square Root Relationship: The relationship between differential pressure and flow rate is non-linear (flow is proportional to the square root of the differential pressure). This can limit the accuracy at lower flow rates.

Typical Applications of Differential Pressure Flow Meters:

- Oil and Gas Production and Refining

- Chemical and Petrochemical Industries

- Power Generation (Steam Flow)

- HVAC Systems

- Custody Transfer of Natural Gas

Head-to-Head Comparison: Magnetic vs. Differential Pressure Flow Meters

Now that we have a solid understanding of each technology, let’s put them side-by-side in a detailed comparison across key performance and operational parameters.

| Feature | Magnetic Flow Meter | Differential Pressure Flow Meter |

|---|---|---|

| Operating Principle | Faraday’s Law of Electromagnetic Induction | Bernoulli’s Principle |

| Fluid Compatibility | Conductive liquids and slurries only | Liquids, gases, and steam |

| Accuracy | High (typically ±0.5% of reading) | Moderate (typically ±1% to ±2% of full scale) |

| Turndown Ratio | High (up to 100:1 or more) | Lower (typically 3:1 to 10:1) |

| Pressure Drop | Negligible | Significant and permanent |

| Moving Parts | None | None in the primary element, but susceptible to wear |

| Maintenance | Low | Higher, requires periodic inspection and cleaning |

| Installation | Requires full pipe, moderate straight pipe runs | Requires long straight pipe runs |

| Initial Cost | Higher for smaller pipe sizes | Lower for larger pipe sizes (with orifice plates) |

| Long-Term Cost | Lower due to low maintenance and no pressure loss | Higher due to energy loss from pressure drop and maintenance |

| Sensitivity to… | Electrical noise | Changes in fluid density, viscosity, and pressure |

| Ideal For | Clean, corrosive, or abrasive conductive liquids | A wide range of fluids, including gases and steam, especially in high-pressure/temperature applications |

Making the Right Choice: A Flow Meter Selection Guide

Choosing between a magnetic and a differential pressure flow meter ultimately depends on a thorough evaluation of your specific application requirements. Here’s a step-by-step guide to help you make an informed decision:

Analyze Your Fluid: The first and most critical step is to understand the properties of the fluid you need to measure.

- Is it conductive? If not, a magnetic flow meter is immediately out of the running.

- Is it a liquid, gas, or steam? DP meters offer the versatility to handle all three.

- Is it clean, or does it contain solids? The non-obstructive design of a mag meter makes it ideal for slurries and dirty fluids. DP meters with orifice plates can clog.

- Is it corrosive or abrasive? Mag meters with appropriate liners can handle these fluids well. DP meter elements can erode or corrode.

Determine Your Accuracy Requirements: How critical is precision to your process?

- For custody transfer, critical chemical dosing, or stringent quality control, the high accuracy of a magnetic flow meter is often the preferred choice.

- For general process monitoring or applications where a slightly lower accuracy is acceptable, a DP flow meter may be sufficient and more cost-effective.

Consider Pressure and Energy Costs:

- If minimizing pressure loss is a priority to reduce pumping costs and maintain system efficiency, the magnetic flow meter is the clear winner.

- If a certain amount of pressure drop is acceptable and the initial cost is a primary driver for a large pipeline, a DP meter might be the more economical option upfront.

Evaluate Installation Constraints:

- Do you have ample straight pipe runs available? If not, the shorter straight pipe requirements of some magnetic flow meters might be advantageous. DP meters are less forgiving of poor installation conditions.

- Is the pipe always full? Mag meters require a full pipe for accurate measurement.

Assess Maintenance and Long-Term Costs:

- Are you looking for a “fit and forget” solution with minimal maintenance? The no-moving-parts design of a magnetic flow meter makes it very appealing.

- Are you prepared for periodic inspections, cleaning, and potential replacement of the primary element? If so, a DP meter can be a reliable workhorse.

Frequently Asked Questions (FAQs)

Q1: Can a magnetic flow meter be used for gases? No, magnetic flow meters rely on the fluid being electrically conductive. Since gases are not conductive, a mag meter cannot be used to measure their flow.

Q2: What is the main cause of inaccuracy in a differential pressure flow meter? The most common causes of inaccuracy in DP flow meters are improper installation (insufficient straight pipe runs), wear and tear of the primary element, and clogging of the pressure taps or the primary element itself.

Q3: Which flow meter is better for wastewater applications? Magnetic flow meters are generally the preferred choice for wastewater applications due to their ability to handle solids and slurries without clogging and their high accuracy.

Q4: Is a venturi meter a type of differential pressure flow meter? Yes, a venturi meter is a type of primary element used in differential pressure flow measurement. It offers lower permanent pressure loss compared to an orifice plate but is typically more expensive.

Q5: What are the liner materials used in magnetic flow meters? Common liner materials for magnetic flow meters include PTFE, PFA, neoprene, and hard rubber. The choice of liner depends on the chemical compatibility and temperature of the fluid being measured.

The Final Verdict: A Tale of Two Technologies

The battle between magnetic and differential pressure flow meters is not about one being definitively “better” than the other. Instead, it’s a matter of choosing the right tool for the right job.

The magnetic flow meter emerges as the modern, high-precision champion for conductive liquids. Its non-invasive nature, exceptional accuracy, and low maintenance requirements make it an ideal choice for a vast array of applications, particularly those involving challenging fluids like slurries and corrosive chemicals. While the initial investment might be higher, the long-term benefits of reduced energy consumption and minimal upkeep often lead to a lower total cost of ownership.

The differential pressure flow meter, on the other hand, is the seasoned and versatile veteran. Its ability to measure liquids, gases, and steam, coupled with its suitability for high-pressure and high-temperature environments, ensures its continued relevance in many industrial sectors. For large-diameter pipes where initial cost is a major consideration, the humble orifice plate DP meter remains a compelling and cost-effective solution.

Ultimately, by carefully considering the factors outlined in this comprehensive comparison – from fluid properties and accuracy requirements to installation constraints and long-term costs – you can confidently select the flow meter that will provide reliable, accurate, and efficient measurement for years to come.

Use the below interactive tool to select Magnetic/DP Flow meter

Is the fluid electrically conductive?

What is the fluid state?

Is the liquid clean, or does it contain solids/slurries?

Is the fluid corrosive or abrasive?

How critical is measurement accuracy?

Is minimizing pressure loss and energy cost a high priority?

Are straight pipe runs limited at the installation site?

Is the pipe guaranteed to be full at all times during measurement?

What is your preference for maintenance?

Select DP Meter

Magnetic meters require conductive fluid. A Differential Pressure (DP) meter or another technology is necessary.

Select DP Meter

For gas or steam applications, a Differential Pressure (DP) meter is the versatile and appropriate choice.

Recommend: Magnetic Meter

The non-obstructive design of a magnetic meter makes it ideal for liquids containing solids or slurries, preventing clogging.

Recommend: Magnetic Meter

With the appropriate liner, a magnetic meter is a strong choice for corrosive or abrasive fluids, offering better longevity than DP elements.

Recommend: Magnetic Meter

For high-priority applications like custody transfer or chemical dosing, the superior accuracy of a magnetic meter is preferred.

Recommend: Magnetic Meter

The magnetic meter is the clear winner for minimizing pressure loss, which reduces pumping costs and improves energy efficiency.

Advantage: Magnetic Meter

Magnetic meters typically have shorter straight-pipe run requirements, making them advantageous for installations with limited space.

Warning: Consider DP Meter

Magnetic meters require a full pipe for accurate measurement. If the pipe may not be full, a DP meter could be more reliable.

Recommend: Magnetic Meter

With no moving or intruding parts, the magnetic meter is an excellent low-maintenance, "fit and forget" solution.

Recommend: DP Meter

If periodic inspection and potential element replacement are acceptable, a DP meter is a cost-effective and reliable workhorse.