Overcoming Measurement Challenges with Ultrasonic Level Technology

In the world of industrial process control, accurately and reliably measuring the level of liquids and bulk solids is paramount. From ensuring the quality of a final product to preventing costly spills and ensuring worker safety, precise level measurement is a cornerstone of operational efficiency. However, the plant floor is often a hostile environment for sensitive instrumentation. Dust, corrosion, temperature fluctuations, and the inherent properties of the materials being measured can all conspire to thwart accurate readings.

For decades, various technologies have been employed to tackle these challenges, each with its own set of strengths and weaknesses. But one technology has consistently proven its versatility and reliability in a wide array of applications: ultrasonic level measurement. This non-contact method offers a robust solution to many of the persistent problems that plague traditional level sensing techniques.

This in-depth blog post will explore the common measurement challenges encountered in industrial settings and detail how ultrasonic level technology provides an effective and often elegant solution. We will delve into the fundamental principles of ultrasonic sensing, its advantages and limitations, and how modern advancements are further expanding its capabilities.

The Persistent Challenges of Level Measurement

Before we can appreciate the solutions offered by ultrasonic technology, it’s crucial to understand the hurdles that process engineers and technicians face daily. These challenges can be broadly categorized into environmental factors, material properties, and mechanical interferences.

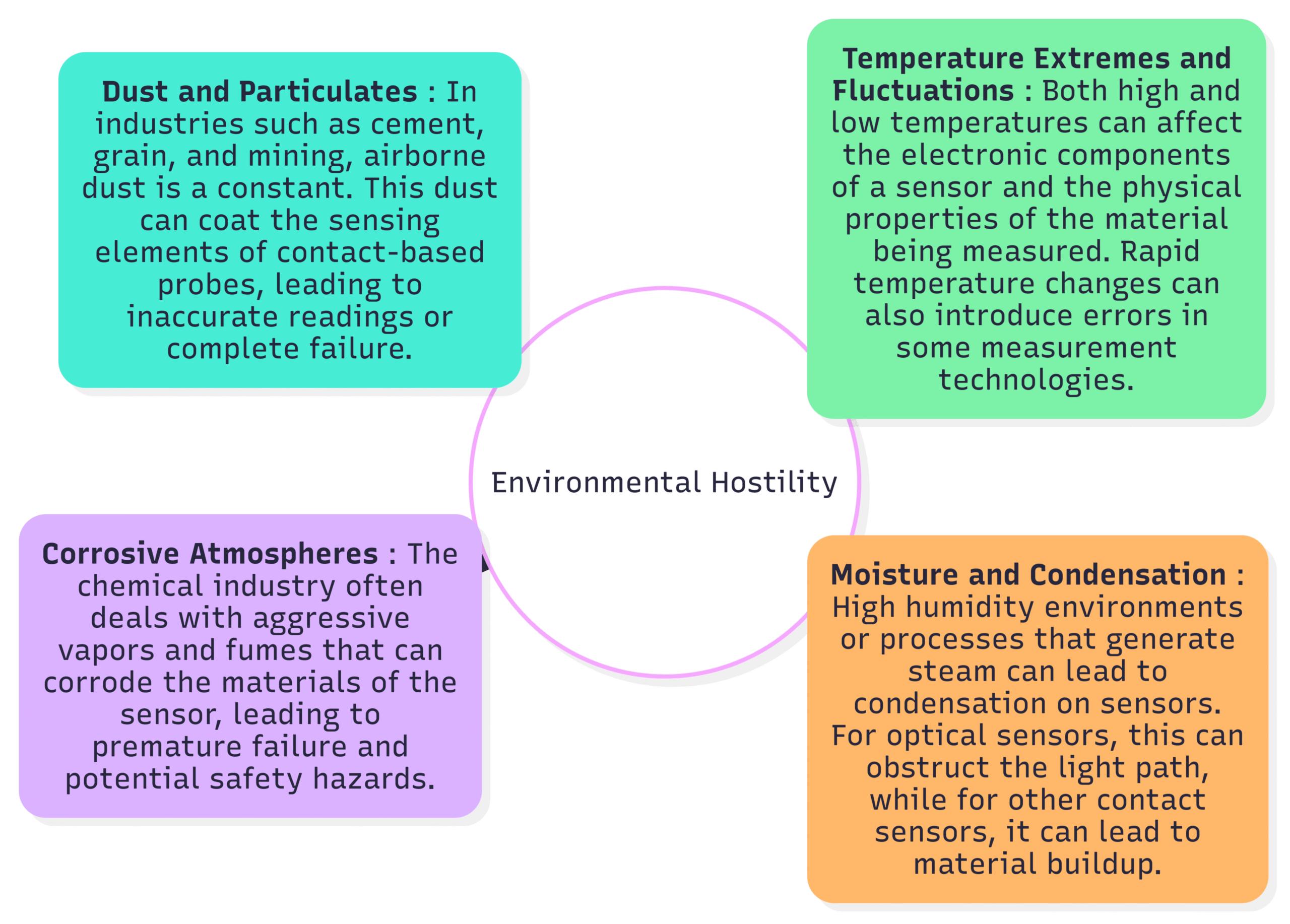

Environmental Hostility

The ambient conditions surrounding a storage tank or vessel can significantly impact the performance and longevity of level sensors.

Dust and Particulates: In industries such as cement, grain, and mining, airborne dust is a constant. This dust can coat the sensing elements of contact-based probes, leading to inaccurate readings or complete failure.

Moisture and Condensation: High humidity environments or processes that generate steam can lead to condensation on sensors. For optical sensors, this can obstruct the light path, while for other contact sensors, it can lead to material buildup.

Corrosive Atmospheres: The chemical industry often deals with aggressive vapors and fumes that can corrode the materials of the sensor, leading to premature failure and potential safety hazards.

Temperature Extremes and Fluctuations: Both high and low temperatures can affect the electronic components of a sensor and the physical properties of the material being measured. Rapid temperature changes can also introduce errors in some measurement technologies.

The Nature of the Material

The substance being measured is often the primary source of measurement difficulty.

Corrosive and Abrasive Materials: Liquids like acids and alkalis, and solids like sand and gravel, can physically or chemically attack contact-based sensors, leading to a short service life.

Viscous and Sticky Fluids: Materials such as molasses, paint, and some slurries can coat and build up on any sensor they touch, rendering them ineffective.

Foaming and Turbulence: The presence of foam on the surface of a liquid can create a false level indication for many sensor types. Similarly, agitated or turbulent surfaces can cause erratic readings.

Varying Dielectric Constants: For technologies like capacitance level sensors, changes in the composition and moisture content of the material can alter its dielectric constant, leading to a need for frequent recalibration.

Mechanical and Structural Hurdles

The physical configuration of the tank or silo itself can present obstacles.

Internal Obstructions: Ladders, agitator blades, and support beams within a vessel can create false echoes for non-contact technologies or physically interfere with contact probes.

Vessel Shape and Size: Irregularly shaped tanks or very tall silos can make it difficult to find a suitable mounting location for a sensor that provides a clear and representative measurement.

Limited Headspace: In some applications, there may be very little clearance above the maximum level of the material, which can be a problem for sensors with a significant “blocking distance” or “dead band.”

The Ultrasonic Solution:

Ultrasonic level sensors offer a powerful and versatile solution to many of these challenges by employing a simple yet elegant principle: time-of-flight.

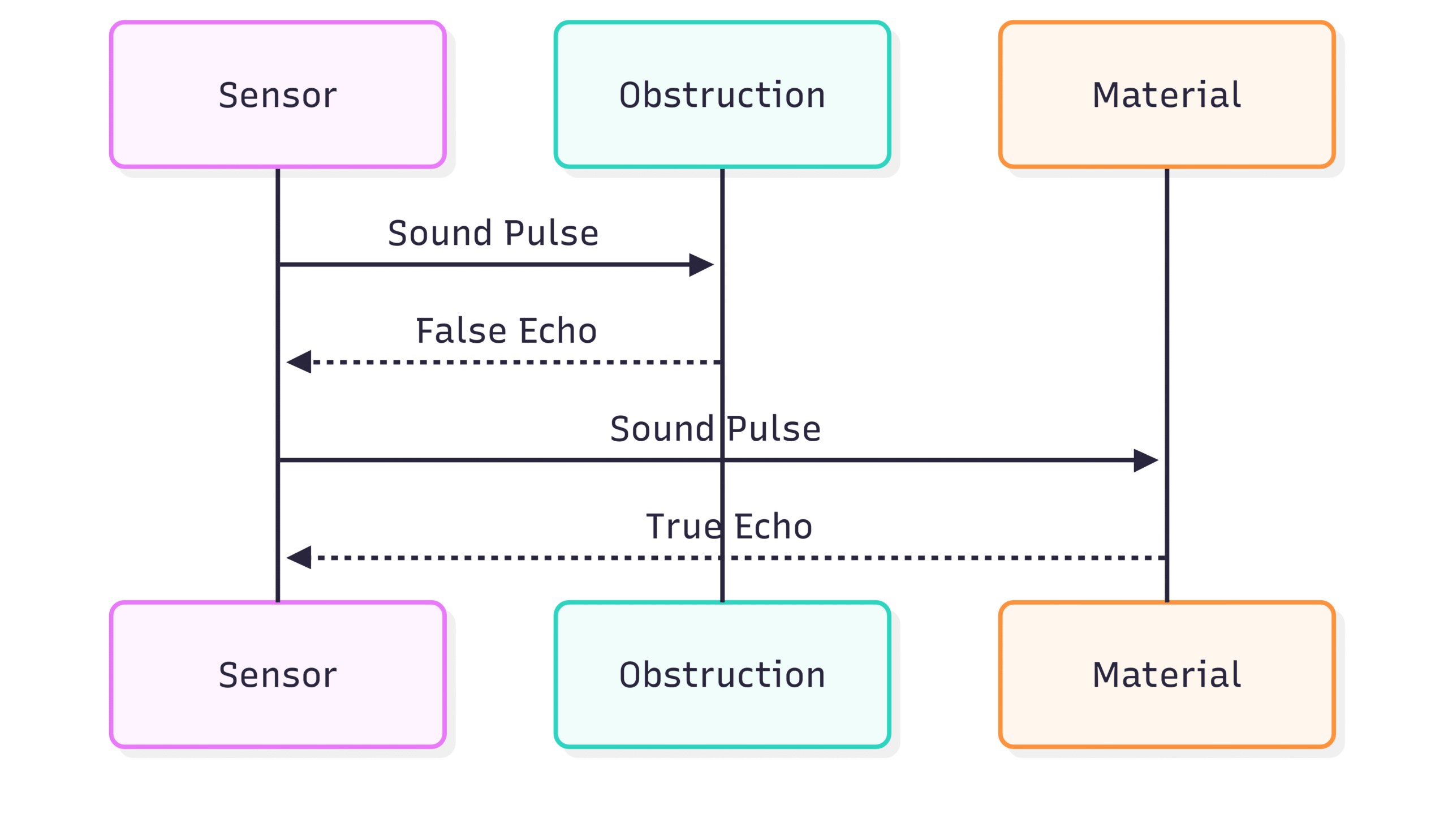

How It Works: The Echo Principle

An ultrasonic level sensor is mounted at the top of a tank or vessel, with its transducer aimed downwards at the material surface. The sensor emits a short burst of high-frequency sound waves (typically in the range of 20 to 200 kHz), which are well above the range of human hearing. These sound waves travel through the air, reflect off the surface of the liquid or solid, and the resulting echo is detected by the same transducer.

The sensor’s sophisticated electronics measure the time it takes for the sound pulse to travel from the transducer to the material surface and back. Since the speed of sound in air is a known quantity, the distance to the material can be calculated with a high degree of accuracy using the following formula:

The sensor then subtracts this distance from the known total height of the vessel to determine the material level.

Key Advantages of Ultrasonic Technology

The non-contact nature of ultrasonic measurement is the foundation of its many advantages:

Unaffected by Material Properties: Because the sensor never touches the material, it is immune to issues of corrosion, abrasion, viscosity, and stickiness. This makes it an ideal choice for a vast range of liquids and solids. Furthermore, changes in the material’s density, conductivity, or dielectric constant do not affect the measurement.

Minimal Maintenance: With no moving parts to wear out and no need for routine cleaning of a probe, ultrasonic sensors are exceptionally low-maintenance. This translates to reduced downtime and lower long-term cost of ownership.

Reliable in Dusty and Moist Environments: While very heavy dust or steam can sometimes attenuate the sound signal, modern ultrasonic sensors with advanced signal processing can often “see” through these challenging conditions. The downward-facing transducer is also less prone to the accumulation of condensation compared to some other technologies.

Easy Installation and Commissioning: Installation is typically straightforward, involving mounting the sensor on a suitable nozzle at the top of the tank. Configuration is also generally simple, often requiring only the input of the tank dimensions.

Navigating the Limitations: Best Practices and Advanced Features

While ultrasonic technology is incredibly versatile, it’s not without its limitations. However, understanding these limitations and employing best practices and modern sensor features can overcome most potential issues.

Common Limitations and How to Address Them

Blanking Distance: Every ultrasonic sensor has a “blanking distance” or “dead band” immediately in front of the transducer face. This is a short zone where the sensor cannot make a reliable measurement because the transducer is still “ringing” from transmitting the initial pulse.

Solution: Ensure the sensor is mounted high enough so that the maximum material level never enters this blanking distance. Reputable manufacturers will clearly specify this distance in their product documentation.

False Echoes from Obstructions: The conical sound beam emitted by the transducer can sometimes reflect off internal tank structures like ladders, pipes, or even rough welds on the tank wall, creating false echoes that can be misinterpreted as the material level.

Solution: Careful selection of the mounting location is key. The sensor should be positioned to have a clear, unobstructed path to the material surface. Many modern sensors also feature advanced algorithms that can filter out these false echoes. In particularly challenging applications, a “stilling well” or “standpipe” can be used to guide the sound beam directly to the surface.

Temperature Compensation: The speed of sound in air changes with temperature. If left uncompensated, this can introduce inaccuracies into the level measurement.

Solution: Virtually all modern ultrasonic level sensors have an integrated temperature sensor. This allows the device to automatically compensate for changes in the ambient temperature within the tank, ensuring consistent accuracy.

Heavy Vapors and Fumes: In some chemical applications, heavy vapor layers can form above the liquid. These layers can have a different density and temperature than the surrounding air, which can affect the speed of the sound pulse and potentially dampen the signal.

Solution: In such cases, a different technology like guided-wave radar might be a more suitable choice. However, some advanced ultrasonic sensors with higher power output and more sensitive receivers can perform reliably even in the presence of moderate vapors.

Extreme Vacuum or Pressure: Ultrasonic sensors rely on air as a medium to transmit the sound waves. Therefore, they are not suitable for use in a vacuum. High-pressure applications can also affect the speed of sound and may exceed the mechanical limitations of the sensor’s housing.

Solution: For high-pressure or vacuum applications, technologies such as differential pressure or radar level transmitters are the recommended alternatives.

Sound-Absorbing Materials: While rare in industrial level measurement, some very soft, fluffy materials can absorb the sound energy rather than reflecting it, making it difficult to get a reliable echo.

Solution: Testing the material with a demonstration unit is always advisable in such niche applications.

The Power of Modern Signal Processing

The “brain” of a modern ultrasonic level sensor is its microprocessor and the sophisticated software it runs. These are what truly set today’s sensors apart from their predecessors. Advanced signal processing algorithms can:

Distinguish the true material echo from false echoes caused by obstructions, noise, or even the sensor’s own electronic noise.

Track the material level with greater confidence, even when the surface is turbulent or the echo is weak.

Provide diagnostic information about the quality of the measurement, alerting operators to potential issues before they become problems.

Ultrasonic vs. The Competition: Choosing the Right Tool for the Job

While ultrasonic technology is a powerful tool, it’s important to understand where it fits within the broader landscape of level measurement technologies.

Ultrasonic vs. Radar

Radar level transmitters are another popular non-contact technology. They operate on a similar time-of-flight principle but use microwave pulses instead of sound waves.

When to Choose Ultrasonic: Ultrasonic sensors are often more cost-effective than radar, especially for shorter measurement ranges. They also tend to have a narrower beam angle, which can be advantageous in tanks with many internal obstructions. They are an excellent choice for a wide range of liquid and simple solid applications.

When to Choose Radar: Radar is unaffected by changes in temperature, pressure, or the presence of vapors. This makes it the superior choice for high-temperature, high-pressure chemical applications, or where heavy vapors are a constant. Radar can also “see” through foam to a greater extent than ultrasonics.

Ultrasonic vs. Contact Technologies (Floats, Capacitance, Hydrostatic)

The Clear Advantage of Non-Contact: The primary advantage of ultrasonic over any contact technology is the elimination of material compatibility issues, buildup problems, and mechanical wear. For corrosive, sticky, or abrasive materials, non-contact is almost always the preferred approach.

Applications Across Industries: Where Ultrasonic Shines

The versatility of ultrasonic level technology has led to its widespread adoption in a diverse range of industries:

Water and Wastewater: From monitoring the level of water in reservoirs and tanks to controlling the flow in open channels and managing the level in chemical storage tanks for water treatment, ultrasonics are a mainstay of this industry.

Chemical Processing: For the storage of a wide variety of bulk chemicals, acids, and bases, the non-contact nature of ultrasonic sensors makes them an ideal and safe choice.

Food and Beverage: Ultrasonic sensors are used to measure the level of ingredients in tanks and silos, from liquid chocolate and oils to grains and powders. Their hygienic design, with no intrusion into the vessel, is a key benefit.

Agriculture: Farmers and agricultural cooperatives rely on ultrasonic sensors to manage the level of feed in silos, water in irrigation tanks, and liquid fertilizer in storage.

Plastics and Aggregates: Measuring the level of plastic pellets in hoppers or sand and gravel in storage silos are common and effective applications for ultrasonic technology.

Conclusion: A Sound Choice for Modern Measurement

The challenges of industrial level measurement are as diverse as the processes themselves. From corrosive chemicals to swirling dust and internal tank obstructions, a reliable level sensor must be robust, accurate, and adaptable. Ultrasonic level technology, with its non-contact principle, has proven time and again to be a sound choice for overcoming these hurdles.

By eliminating material compatibility concerns, minimizing maintenance requirements, and providing consistent accuracy, ultrasonic sensors empower industries to operate more efficiently, safely, and cost-effectively. As sensor technology continues to advance, with more intelligent signal processing and more robust designs, the capabilities of ultrasonic level measurement will only continue to expand, solidifying its place as a cornerstone of modern process automation. When faced with a challenging level measurement application, it is always wise to listen for the echo of a technology that has stood the test of time and continues to deliver exceptional performance.