Radar and Guided Wave Radar for Interface Level Measurement

In the intricate world of industrial process control, the precise measurement of interface levels between two immiscible liquids is a critical, yet often challenging, task. From separating oil and water in the energy sector to managing layers in chemical reactors, accurate interface detection is paramount for efficiency, safety, and product quality. Two of the leading technologies at the forefront of this challenge are non-contact radar and guided wave radar (GWR). While both leverage the principles of high-frequency electromagnetic waves, their methodologies, strengths, and ideal applications differ significantly. This comprehensive guide will delve into the nuances of each technology, providing a detailed comparison to help you navigate the complexities of interface level measurement and select the optimal solution for your needs.

The Fundamental Principle: Time-of-Flight and Dielectric Constants

At the heart of both radar and guided wave radar technologies lies the Time-of-Flight (ToF) principle. A microwave signal is emitted from a transmitter, travels to the surface of the medium, reflects, and is then detected by a receiver. The time it takes for the signal to make this round trip is directly proportional to the distance to the surface. By knowing the speed of the signal (which is close to the speed of light), the level of the liquid can be accurately calculated.

The key to successful interface level measurement with radar technology hinges on the dielectric constant (ε_r) of the liquids involved. The dielectric constant is a measure of a material’s ability to store electrical energy in an electric field. When the emitted radar wave encounters a change in the dielectric constant, such as the boundary between two different liquids, a portion of the wave is reflected. The greater the difference in the dielectric constants of the two liquids, the stronger the reflected signal, and the more reliable the measurement.

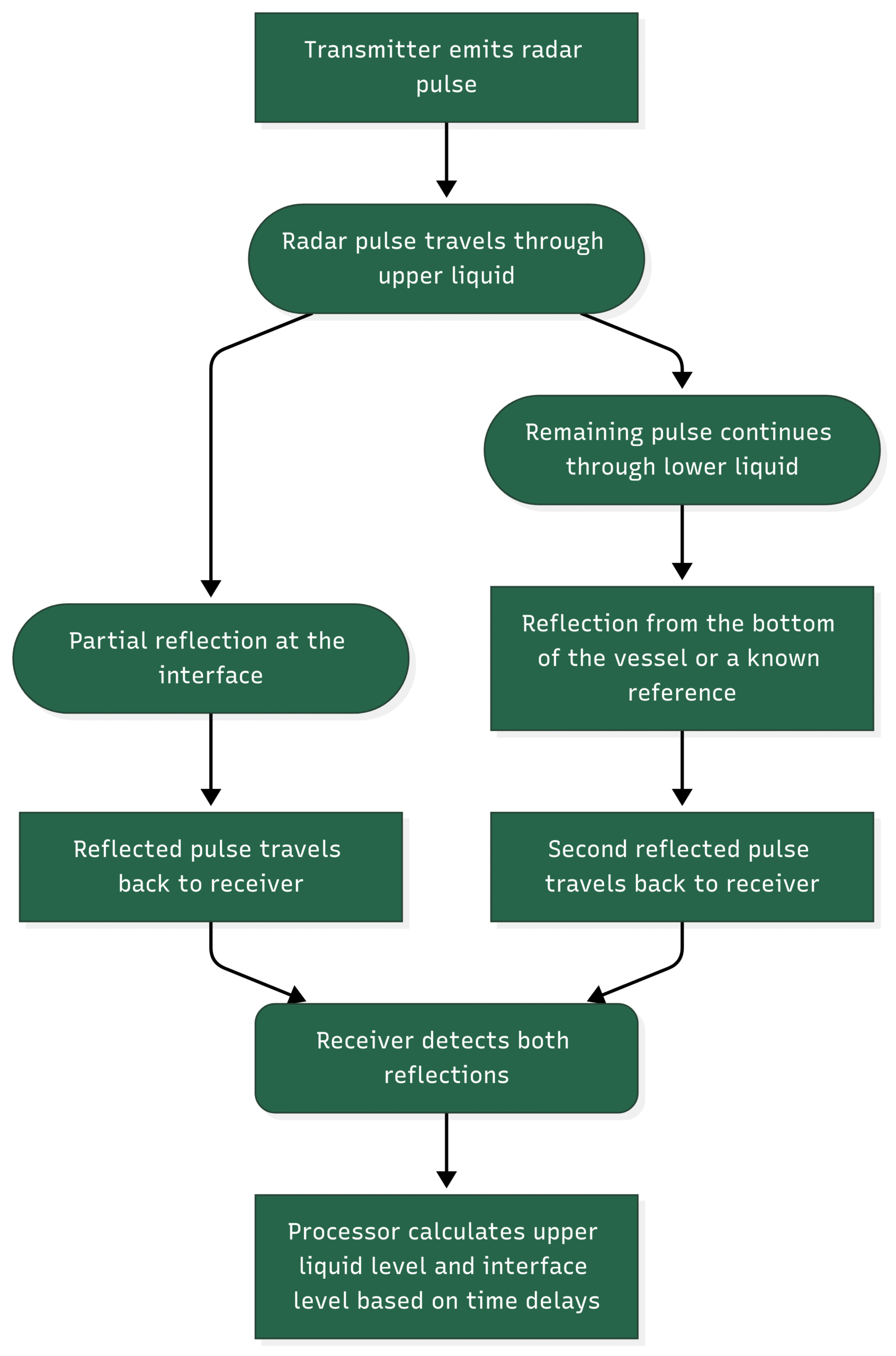

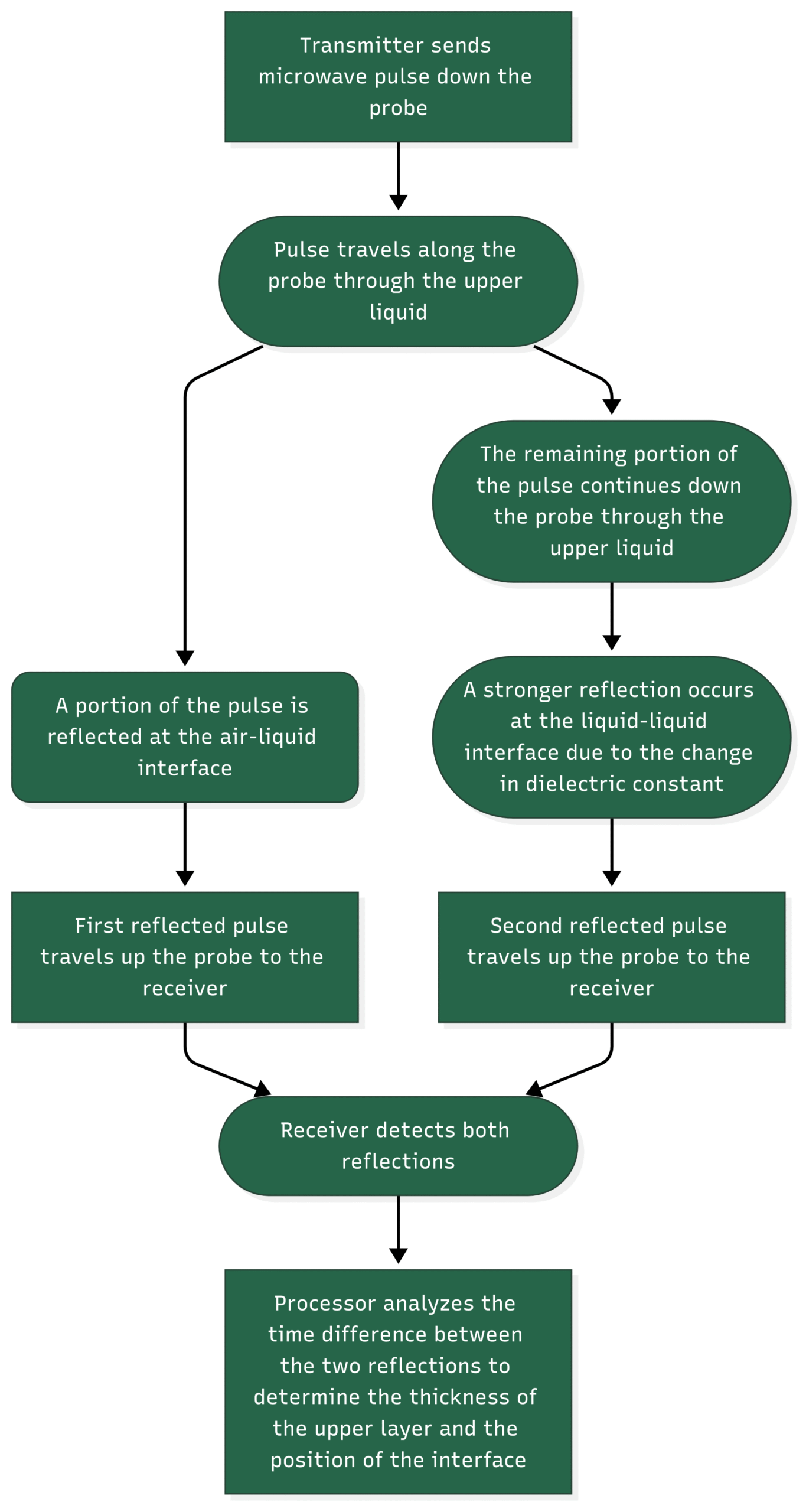

How it Works: A Visual Breakdown

To better understand the operational differences, let’s visualize the process with mermaid block diagrams.

Non-Contact Radar for Interface Level Measurement

Guided Wave Radar for Interface Level Measurement

Non-Contact Radar: The Overhead Advantage

Non-contact radar level transmitters are mounted at the top of a tank and emit radar pulses downwards towards the liquid surface. This “top-down” approach offers the significant advantage of having no direct contact with the process medium.

Advantages of Non-Contact Radar for Interface Measurement

No Wetted Parts: This is the most significant benefit, especially when dealing with corrosive, abrasive, or viscous liquids. The absence of a probe eliminates concerns about material compatibility, coating, and mechanical failure due to process conditions.

Unaffected by Liquid Properties: The accuracy of non-contact radar is largely independent of changes in liquid density, viscosity, and, to a large extent, temperature and pressure.

Suitable for Harsh Environments: The non-intrusive nature makes it ideal for applications with aggressive chemicals or where contamination of the medium is a concern.

Simplified Installation: Installation is often simpler and less invasive than with GWR, as it only requires a suitable nozzle at the top of the vessel.

Disadvantages and Challenges of Non-Contact Radar

Weaker Reflections from Interfaces: Detecting the interface between two liquids can be challenging for non-contact radar. The initial reflection from the top surface of the upper liquid can be much stronger than the reflection from the interface, potentially masking the weaker interface signal.

Dependence on Calm Surfaces: Turbulence, foam, and agitated surfaces can scatter the radar beam, leading to signal loss and inaccurate readings. While advanced signal processing algorithms can mitigate these effects to some extent, they remain a significant challenge.

Beam Spreading: The radar beam spreads out as it travels from the antenna, which can lead to false echoes from internal tank obstructions like agitators, heating coils, or ladders. Careful mapping of the tank internals is often required.

Dielectric Constant Limitations: For reliable interface detection, there needs to be a significant difference in the dielectric constants of the two liquids. If the dielectric constant of the upper layer is very low, most of the radar energy will penetrate it, making the reflection from the interface stronger and easier to detect. However, if the upper layer has a high dielectric constant, it will reflect a larger portion of the signal, making the interface reflection weaker.

Guided Wave Radar: The Direct Approach

Guided wave radar (GWR), also known as Time Domain Reflectometry (TDR), utilizes a probe (either a rigid rod or a flexible cable) that extends into the process liquid. This probe acts as a waveguide, directing the microwave pulses down into the tank.

Advantages of Guided Wave Radar for Interface Measurement

Superior Interface Detection: GWR is generally considered the more reliable technology for interface level measurement. The guided nature of the microwave pulse concentrates the energy along the probe, resulting in a much stronger and more distinct reflection from the liquid-liquid interface.

Excellent Performance in Challenging Conditions: GWR is largely immune to the effects of foam, vapor, turbulence, and condensation, which can be significant sources of error for non-contact radar. The probe effectively cuts through these disturbances to provide a stable and accurate measurement.

Handles a Wide Range of Dielectric Constants: While a sufficient difference in dielectric constants is still necessary, GWR can often handle applications with lower dielectric differences than non-contact radar. For optimal performance, the upper liquid should have a low dielectric constant (typically ε_r < 10) and the difference in dielectric constants between the two liquids should be greater than 10.

Measures Both Level and Interface Simultaneously: A single GWR transmitter can accurately measure both the overall level of the upper liquid and the position of the interface.

Disadvantages and Challenges of Guided Wave Radar

Wetted Parts: The probe is in direct contact with the process liquids, which introduces considerations for material compatibility. In corrosive environments, exotic and more expensive probe materials may be required.

Potential for Coating and Buildup: Viscous or sticky materials can coat the probe, which can attenuate the signal and affect measurement accuracy. While advanced GWR systems have features to compensate for some buildup, it remains a concern in certain applications.

Installation Complexity: The installation of a GWR probe can be more complex than that of a non-contact radar. The probe length must be carefully selected for the tank height, and in the case of long, flexible probes, proper tensioning is crucial to prevent contact with the tank wall.

Mechanical Stress: The probe can be subject to mechanical stress from agitators or heavy turbulence, which could lead to damage or failure.

Head-to-Head Comparison: Radar vs. Guided Wave Radar for Interface Level Measurement

| Feature | Non-Contact Radar | Guided Wave Radar |

| Principle | Top-down, through-air microwave pulses | Microwave pulses guided by a probe |

| Interface Detection | Can be challenging, relies on significant dielectric difference | Excellent, provides a strong and clear reflection |

| Performance in Foam | Can be severely affected, signal scattering | Largely unaffected, probe cuts through foam |

| Performance in Turbulence | Prone to errors due to surface agitation | Highly reliable, immune to surface conditions |

| Wetted Parts | None | Probe is in direct contact with the process medium |

| Coating/Buildup | Not a concern | A potential issue for viscous or sticky liquids |

| Installation | Generally simpler, requires a top-mounted nozzle | More complex, requires careful probe selection and installation |

| Maintenance | Lower, no wetted parts to clean or replace | May require periodic cleaning of the probe |

| Cost | Initial cost can be higher for high-frequency models | Can be more cost-effective for standard applications |

| Ideal Applications | Corrosive liquids, hygienic applications, tanks with no internal obstructions | Oil-water separation, chemical reactors, challenging process conditions |

Real-World Applications: Where Each Technology Shines

The choice between non-contact radar and GWR for interface level measurement is not a one-size-fits-all decision. The optimal solution depends heavily on the specific application and process conditions.

Case Study: Oil and Water Separation in the Oil & Gas Industry

Challenge: Accurately measuring the interface between crude oil and water in a separator vessel is crucial for optimizing the separation process and preventing water from contaminating the oil stream or oil from being discharged with the water. The presence of an emulsion layer (a mixture of oil and water) can further complicate the measurement.

Optimal Solution: Guided Wave Radar. GWR is the preferred technology for this application. Its ability to provide a strong reflection from the oil-water interface, even in the presence of an emulsion layer, makes it highly reliable. The technology is also adept at handling the often-turbulent conditions within a separator.

Case Study: Chemical Reactor with Corrosive Layers

Challenge: A chemical reactor contains two highly corrosive, immiscible liquids. The interface level needs to be monitored to ensure the reaction proceeds correctly. The use of a wetted sensor would require expensive, exotic materials and would still be at risk of corrosion.

Optimal Solution: Non-Contact Radar. In this scenario, the non-contact nature of radar is a significant advantage. By avoiding any contact with the corrosive chemicals, the longevity and reliability of the measurement system are greatly enhanced. Careful selection of a radar frequency that can effectively penetrate the upper layer and reflect off the interface is key.

The Bottom Line: Making the Right Choice

Choosing between non-contact radar and guided wave radar for interface level measurement requires a thorough understanding of your specific process.

Choose Non-Contact Radar when:

The process liquids are highly corrosive, abrasive, or viscous.

Maintaining a hygienic or sterile environment is critical.

The vessel is free from significant internal obstructions.

The surface of the liquid is relatively calm.

There is a significant difference in the dielectric constants of the two liquids.

Choose Guided Wave Radar when:

You require highly accurate and reliable interface detection.

The process involves foam, vapor, turbulence, or condensation.

You need to measure both the overall level and the interface simultaneously.

The process liquids are not prone to heavy coating or buildup on the probe.

By carefully considering the advantages, disadvantages, and ideal applications of each technology, you can select the most effective and reliable solution for your interface level measurement needs, ultimately leading to improved process efficiency, enhanced safety, and higher product quality. As technology continues to evolve, both non-contact radar and GWR systems are becoming more sophisticated, with advanced signal processing and diagnostic capabilities further enhancing their performance in even the most challenging industrial environments.