Radar Level Measurement for LPG and Crude Oil Storage Tanks

In the high-stakes world of oil and gas, the accurate and reliable measurement of liquefied petroleum gas (LPG) and crude oil in storage tanks is not just a matter of operational efficiency; it’s a cornerstone of safety and environmental protection. For decades, the industry has relied on various level measurement technologies, but one has emerged as a clear frontrunner in terms of precision, reliability, and safety: radar level measurement. This comprehensive guide will explore the intricacies of radar level technology and its application in the challenging environments of LPG and crude oil storage.

The Fundamental Principles of Radar Level Measurement

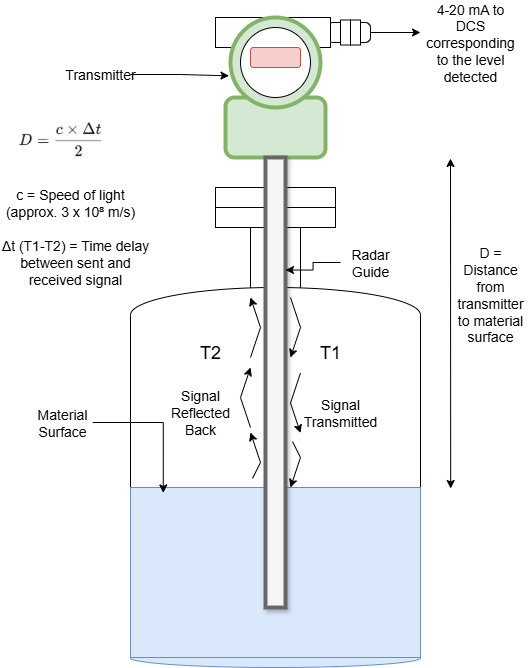

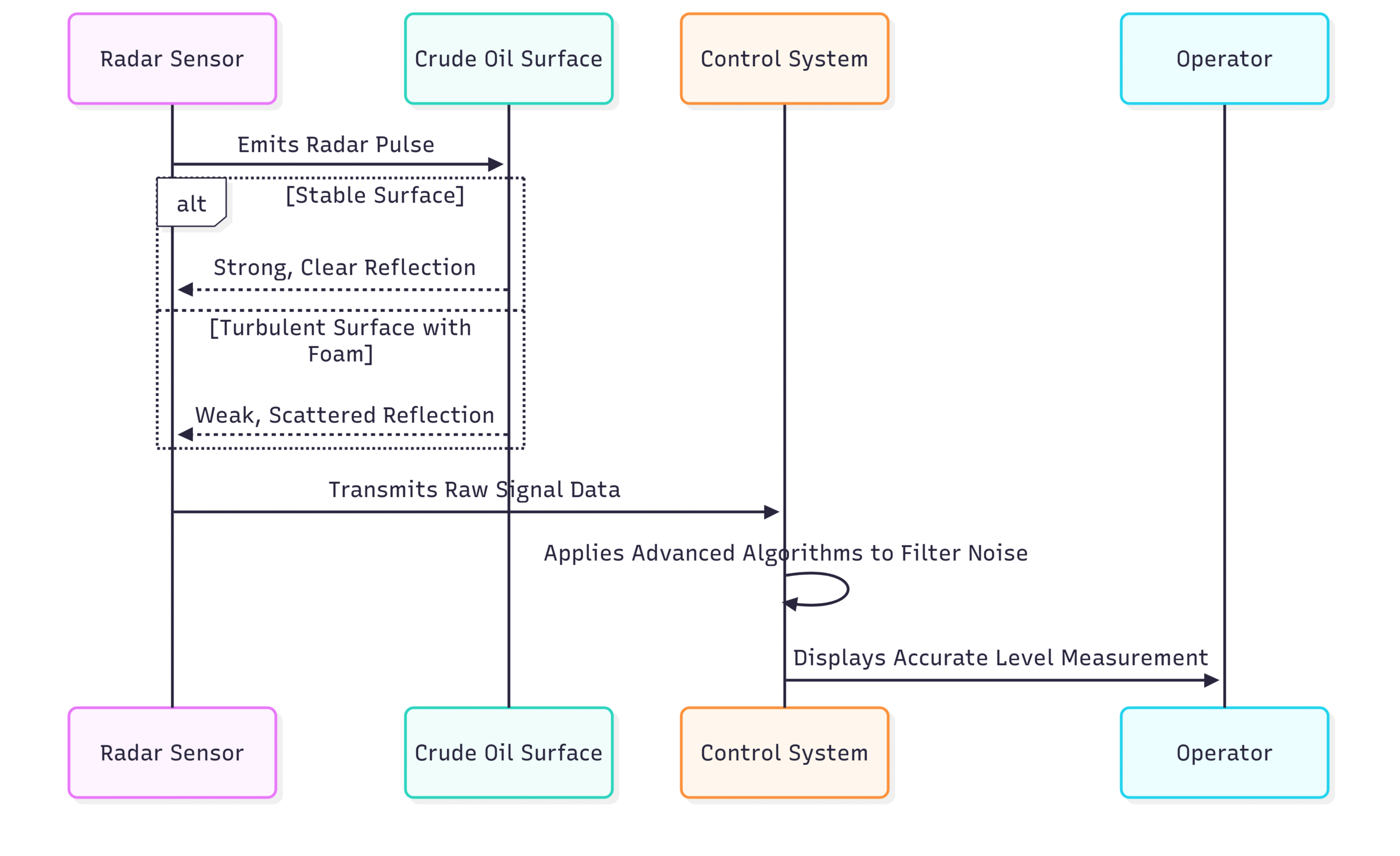

At its core, radar level measurement is a non-contact technology that utilizes the propagation of electromagnetic waves. A radar sensor, mounted on top of a storage tank, emits a continuous or pulsed microwave signal towards the surface of the liquid. This signal, upon hitting the liquid, is reflected back to the sensor. The time it takes for the signal to travel from the sensor to the liquid surface and back—known as the Time of Flight (ToF)—is directly proportional to the distance to the liquid. By subtracting this distance from the total height of the tank, the exact level of the product can be determined with remarkable accuracy.

There are two primary types of radar level transmitters used in industrial applications:

Non-Contacting Radar (NCR): As the name suggests, these sensors have no physical contact with the product being measured. They are mounted on the tank roof and emit radar waves through the vapor space. This makes them ideal for corrosive, viscous, or high-purity applications where contamination is a concern.

Guided Wave Radar (GWR): In this configuration, a rigid or flexible probe extends from the sensor into the tank. The radar pulses travel down this probe, guided directly to the liquid surface and back. GWR is particularly effective in applications with low-dielectric liquids, heavy vapors, or significant turbulence, as the probe ensures a clear and direct signal path.

The choice between NCR and GWR depends on the specific characteristics of the application, including the type of product, tank geometry, and process conditions.

Visualizing the Technology: How Radar Level Measurement Works

The Unique Challenges of Measuring LPG Levels

Liquefied Petroleum Gas (LPG) is stored under high pressure in spherical or cylindrical tanks. This presents a unique set of challenges for level measurement:

High Pressure: The high-pressure environment within LPG tanks can affect the performance and safety of measurement instrumentation.

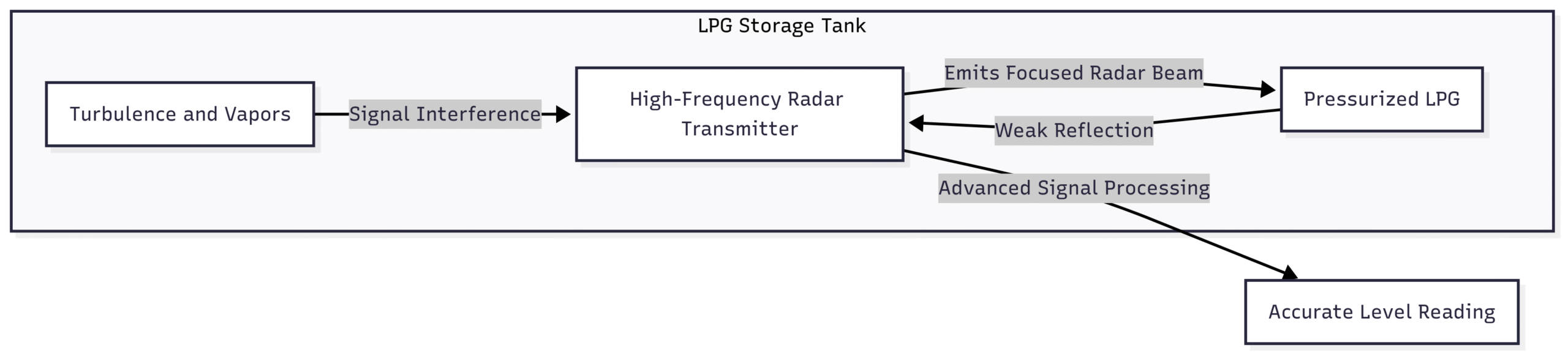

Low Dielectric Constant: LPG has a very low dielectric constant, which means it is a poor reflector of radar signals. This can make it difficult for standard radar sensors to obtain a strong, reliable echo.

Boiling and Flashing: The constant boiling of LPG can create a dense vapor phase and cause “flashing,” where pockets of liquid suddenly turn to gas. This can interfere with the radar signal and lead to inaccurate readings.

Two-Phase Measurement: In some instances, there may be a layer of water or other impurities at the bottom of the tank, requiring the measurement of both the LPG level and the interface level.

Radar’s Edge in LPG Applications

Despite these challenges, radar level transmitters, particularly Guided Wave Radar, have proven to be exceptionally effective for LPG storage.

High-Frequency Radars: Modern radar systems utilize higher frequencies (up to 80 GHz), which allows for a more focused radar beam. This concentrated energy results in a stronger reflection from the low-dielectric LPG surface, ensuring accurate and reliable measurements.

Advanced Signal Processing: Sophisticated algorithms can filter out the “noise” caused by boiling and flashing, providing a stable and accurate level reading.

Still-Pipe Installations: For non-contacting radar in extremely turbulent conditions, a still-pipe can be installed within the tank. The radar signal travels down this pipe, shielded from the turbulence, to provide a clear measurement of the liquid surface.

Interface Measurement: GWR is capable of detecting the interface between two liquids with different dielectric constants, making it ideal for applications where water or other contaminants may be present.

Taming the Complexity of Crude Oil Storage

Crude oil, in its unrefined state, presents a different but equally challenging set of obstacles for level measurement:

Varying Composition and Viscosity: The properties of crude oil can vary significantly depending on its source. Viscosity, in particular, can change with temperature, affecting the performance of some level measurement technologies.

Sedimentation and Sludge: Crude oil often contains suspended solids and water, which can settle at the bottom of the tank, forming a layer of sludge. This can interfere with level measurements and reduce tank capacity.

Surface Turbulence: The filling and emptying of large crude oil tanks can create significant surface turbulence and foam, which can scatter radar signals and lead to inaccurate readings.

Floating Roofs: Many crude oil tanks are equipped with floating roofs to minimize vapor emissions. These roofs can obstruct the signal path of non-contacting radar sensors.

Why Radar Reigns Supreme for Crude Oil

Radar technology, both non-contacting and guided wave, offers robust solutions to these challenges.

Non-Contact Advantage: For non-contacting radar, the absence of moving parts eliminates the risk of mechanical failure due to the viscous and often corrosive nature of crude oil.

Insensitivity to Density and Viscosity: Radar measurements are unaffected by changes in the density, viscosity, or composition of the crude oil.

Bottom and Sludge Detection: Advanced radar systems can be configured to detect not only the top surface of the crude oil but also the interface with any water or sludge at the bottom of the tank, providing valuable data for inventory management and tank cleaning schedules.

Still-Pipe and Bypass Chamber Solutions: For tanks with floating roofs or excessive turbulence, non-contacting radar can be installed in a still-pipe or an external bypass chamber, ensuring a clear and stable measurement path. Guided wave radar is also an excellent option in these scenarios.

Benefits of Adopting Radar Level Measurement

The adoption of radar level measurement technology in LPG and crude oil storage offers a multitude of benefits that translate into improved safety, enhanced efficiency, and greater profitability.

Unparalleled Accuracy and Reliability

Modern radar level transmitters can achieve accuracies of within a few millimeters, providing precise inventory data that is crucial for custody transfer, fiscal accounting, and preventing overfills. Their reliability in harsh and challenging environments minimizes the risk of measurement errors and unscheduled downtime.

Enhanced Safety and Environmental Protection

Accurate level measurement is a critical component of a facility’s safety instrumented system (SIS). By providing reliable data on tank levels, radar technology helps to prevent dangerous overfills that could lead to fires, explosions, and environmental contamination. The non-contact nature of many radar systems also reduces the need for manual dipping and sampling, minimizing personnel exposure to hazardous substances. Adherence to industry standards such as API 2350 for overfill protection is greatly facilitated by the precision of radar technology.

Reduced Maintenance and Lower Lifetime Costs

With no moving parts to wear out or recalibrate, radar level transmitters require minimal maintenance, significantly reducing operational expenditures over the instrument’s lifespan. The ability to perform diagnostics and verification remotely further streamlines maintenance activities and enhances plant availability.

Seamless Integration and Operational Efficiency

Radar level transmitters can be easily integrated into existing plant automation and control systems. The real-time, accurate level data they provide enables optimized inventory management, efficient tanker and pipeline scheduling, and improved overall operational efficiency.

The Future of Level Measurement is Radar

In the dynamic and demanding landscape of the oil and gas industry, the need for precise, reliable, and safe level measurement is paramount. Radar technology has unequivocally demonstrated its superiority in the challenging applications of LPG and crude oil storage. Its ability to overcome the inherent difficulties presented by these substances, coupled with its significant operational and safety benefits, makes it the undisputed technology of choice for modern storage facilities. As the industry continues to evolve and embrace digitalization, the role of intelligent and robust instrumentation like radar level transmitters will only become more critical in ensuring a safe, efficient, and sustainable future.