RTD Working Principle Explained

An interactive and comprehensive guide to Resistance Temperature Detectors: from fundamentals to real-world applications.

1. What is an RTD?

RTD stands for Resistance Temperature Detector. It's a high-precision sensor that measures temperature by correlating the electrical resistance of its core element with temperature. RTDs are celebrated in industrial and scientific fields for their exceptional accuracy, stability, and linearity.

The core principle is simple: as the temperature of a metal changes, so does its electrical resistance. RTDs leverage this predictable relationship to provide incredibly reliable temperature readings.

2. Fundamental Principle

"The resistance of a pure metal increases with an increase in temperature."

Resistance: 107.7 Ω

3. RTD Element Materials

Platinum (Pt) - The Industry Standard

- The most widely used material for RTDs.

- Chemically stable and highly resistant to corrosion.

- Offers exceptional accuracy and repeatability.

- Standard RTDs are often called Pt100 (100 Ω at 0°C) or Pt1000 (1000 Ω at 0°C).

Nickel (Ni)

- Less expensive than platinum.

- Has a more nonlinear resistance-temperature response.

- Suitable for a limited temperature range.

Copper (Cu)

- Provides excellent linearity.

- Limited temperature range and susceptible to oxidation.

- Not as common as platinum or nickel in industrial use.

4. Temperature Coefficient (α)

The coefficient 'α' (alpha) defines how much an RTD's resistance changes per degree Celsius. For industrial platinum, α is typically 0.00385 Ω/Ω/°C.

Calculated Resistance: 138.51 Ω

5. RTD Wire Configurations

Two-Wire

Simplest but least accurate. Lead wire resistance adds to the measurement, causing errors.

Three-Wire (Most Common)

Offers a great balance of cost and accuracy by compensating for lead wire resistance.

Four-Wire (Highest Accuracy)

Completely eliminates lead wire resistance effects. Used for precision lab measurements.

6. RTD Working Circuits

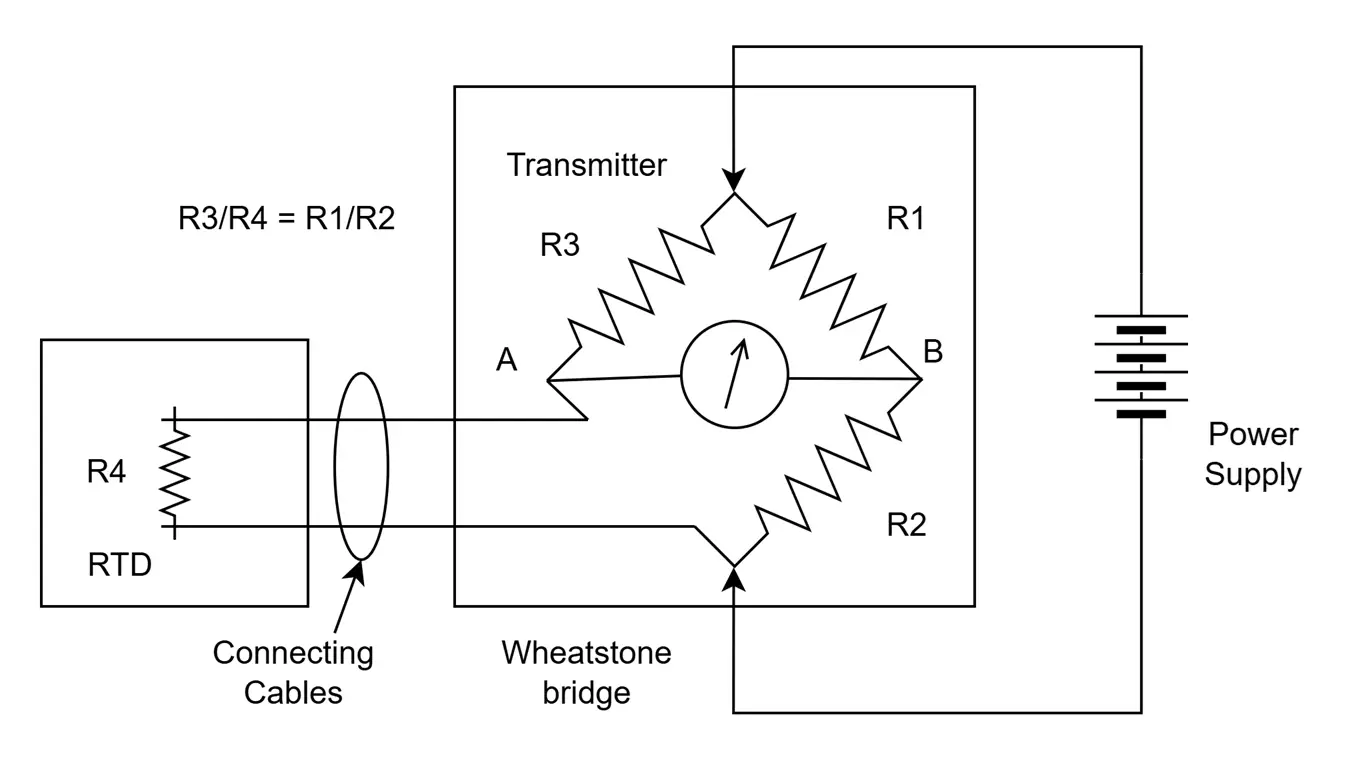

a. Wheatstone Bridge

The RTD forms one "arm" of the bridge. As its resistance changes with temperature, the bridge becomes unbalanced, producing a voltage that corresponds to the temperature.

b. Constant Current Source

A precise, stable current is passed through the RTD. The voltage across the RTD is measured. Using Ohm's Law (V = I × R), the resistance (and thus temperature) can be calculated accurately.

7. Key Properties

- Accuracy: High precision, with Class A Pt100 RTDs accurate to ±0.15°C at 0°C.

- Linearity: Nearly linear output, making them easy to interface with control systems.

- Stability: Extremely stable over time with very little drift, ensuring long-term reliability.

10. Common Applications of RTDs

11. Advantages

- High accuracy and precision

- Excellent long-term stability

- Wide operating temperature range

- Repeatable and consistent readings

- Predictable and nearly linear output

12. Limitations

- Higher cost than thermocouples

- Slower response time

- Sensitive to mechanical shock

- Potential for self-heating errors

- Requires lead wire compensation

13. RTD vs. Thermocouple vs. Thermistor

| Feature | RTD | Thermocouple | Thermistor |

|---|---|---|---|

| Accuracy | High | Moderate | High (in narrow range) |

| Stability | Excellent | Fair | Poor over time |

| Linearity | Good | Poor | Poor (Highly non-linear) |

| Temp. Range | Wide (-200 to 600°C) | Very Wide (-200 to 1800°C) | Narrow (-100 to 150°C) |

| Response Time | Slow | Fast | Very Fast |

| Cost | Moderate to High | Low | Low |

Conclusion

RTDs are premier temperature sensors, prized for their accuracy, stability, and reliability. While they come at a higher cost and have a slower response time compared to alternatives, their superior performance makes them the ideal choice for critical applications where precision cannot be compromised. The Pt100 remains the gold standard, trusted in countless industrial and scientific processes worldwide.

1. Introduction to RTD

RTD stands for Resistance Temperature Detector. It is a temperature sensor that measures temperature by correlating the resistance of the RTD element with temperature. RTDs are widely used in industrial, laboratory, and commercial applications due to their accuracy, stability, repeatability, and linearity.

An RTD relies on the predictable change in the electrical resistance of metals with temperature. As the temperature increases, the resistance of the metal also increases in a known and repeatable way, making it suitable for precise temperature measurement.

2. Fundamental Principle of RTD

The RTD is based on the principle of electrical resistance of metals:

“The resistance of a pure metal increases with an increase in temperature.”

This characteristic is defined mathematically using the temperature coefficient of resistance (TCR).

Basic Relationship:

3. RTD Element Materials

RTDs are typically made using pure metals with stable and repeatable resistance-temperature characteristics. The most common materials used are:

Platinum (Pt)

Most widely used material

Chemically stable and corrosion-resistant

High accuracy and repeatability

Standard RTDs are often called Pt100 (100 ohms at 0°C)

Nickel (Ni)

Less expensive than platinum

More nonlinear response

Limited temperature range

Copper (Cu)

Excellent linearity

Limited temperature range

Susceptible to oxidation and corrosion

Among these, platinum RTDs are the industry standard, especially in industrial process control, due to their superior properties.

4. Temperature Coefficient of Resistance (α)

The temperature coefficient of resistance α\alphaα is a material-specific constant that indicates how much the resistance of the material changes per degree Celsius.

For example, for platinum:

α≈0.00385 Ω/Ω/°C

This means a platinum wire of 100 Ω at 0°C will have approximately:

138.5 Ω at 100°C

119.25 Ω at 50°C

This predictable behavior allows accurate temperature measurement.

5. RTD Configuration Types

RTD Wire Configurations

To measure the resistance accurately and eliminate errors due to lead wire resistance, RTDs are typically wired in one of the following ways:

1. Two-wire RTD

Simplest configuration

One wire at each end of the RTD element

Lead wire resistance adds to the sensor resistance (error)

2. Three-wire RTD

Most common industrial configuration

Two wires on one end, one on the other

Assumes lead wire resistance is equal

Bridge circuit cancels out lead wire resistance

Offers a good balance of cost and accuracy

3. Four-wire RTD

Most accurate configuration

Completely eliminates the effect of lead wire resistance

Used in laboratory and precision measurements

6. RTD Working Circuit

To measure temperature using an RTD, the change in resistance must be detected accurately. There are two typical methods:

a. Wheatstone Bridge Circuit

A Wheatstone bridge is used to detect small changes in resistance.

The RTD forms one arm of the bridge.

As temperature changes, the resistance of the RTD changes.

This causes an imbalance in the bridge, generating a differential voltage.

This voltage is amplified and calibrated to display temperature.

b. Constant Current Source Method

A precise current (usually in the range of 1 mA) is passed through the RTD.

The voltage drop across the RTD is measured using Ohm’s law:

V=I⋅RV

As resistance changes with temperature, voltage changes accordingly.

This voltage is then used to calculate the temperature.

7. RTD Accuracy, Stability, and Linearity

Accuracy

RTDs are known for their high accuracy compared to thermocouples and thermistors. A typical Class A Pt100 RTD has an accuracy of ±0.15°C at 0°C.

Linearity

Platinum RTDs are nearly linear over a wide temperature range. However, for very precise applications, calibration tables or polynomial equations are used to account for slight non-linearity.

Stability

Platinum RTDs are extremely stable over time. They show very little drift even after years of operation, making them ideal for applications where long-term accuracy is critical.

8. RTD Standards

RTDs are manufactured in accordance with international standards such as:

IEC 60751 (International Standard)

Nominal resistance (e.g., 100 Ω at 0°C)

Tolerance classes (A, B, AA)

Temperature coefficient (usually 0.00385/°C for industrial RTDs)

Tolerance Classes:

Class AA: ±(0.1 + 0.0017 × |t|) °C

Class A: ±(0.15 + 0.002 × |t|) °C

Class B: ±(0.3 + 0.005 × |t|) °C

The higher the class, the better the accuracy.

9. RTD Response Time

The response time of an RTD depends on:

Element size and material

Sheath and insulation

Medium (air, liquid, or gas)

Installation (immersed, surface-mounted)

Generally, RTDs have a slower response time than thermocouples due to their construction and mass. However, for applications where speed is not critical, RTDs are preferred for their accuracy.

10. Applications of RTD

RTDs are used in many industrial, scientific, and commercial applications due to their reliability and accuracy.

Industrial Applications

Power plants

Refineries

Chemical industries

Food and beverage

Pharmaceutical processing

HVAC systems

Scientific Applications

Laboratories

Environmental monitoring

Meteorological instruments

Consumer Applications

Appliances

Air conditioners

Water heaters

11. Advantages of RTDs

High accuracy and precision

Excellent stability over time

Wide temperature range (typically −200°C to +600°C)

Repeatability: consistent readings over multiple cycles

Predictable and nearly linear output

Long-term reliability, especially in controlled environments

12. Limitations of RTDs

Higher cost compared to thermocouples and thermistors

Slower response time

Sensitivity to mechanical shock and vibration

Self-heating due to excitation current (must be minimized)

Requires careful lead wire compensation (especially for 2-wire)

13. RTD vs. Thermocouple vs. Thermistor

| Feature | RTD | Thermocouple | Thermistor |

|---|---|---|---|

| Sensing Element | Metal (e.g., platinum) | Dissimilar metals junction | Semiconductor |

| Accuracy | High | Moderate | High |

| Stability | Excellent | Fair | Poor over time |

| Linearity | Good | Poor | Poor |

| Temperature Range | −200 to +600°C | −200 to +1800°C | −100 to +150°C |

| Response Time | Slow | Fast | Very fast |

| Cost | Moderate to high | Low to moderate | Low |

14. RTD Calibration

RTDs can be calibrated against standard temperature references like ice baths (0°C), boiling water (100°C), or precision temperature baths. In industrial applications, smart transmitters with digital compensation are used to linearize and correct RTD outputs.

Calibration ensures:

Accuracy within specified tolerances

Detection of drift or damage

Compliance with quality systems (e.g., ISO 9001, FDA)

Conclusion

RTDs are highly accurate, stable, and reliable temperature sensors based on the principle that the resistance of a metal changes predictably with temperature. Platinum RTDs (especially Pt100) are the most widely used type due to their linear behavior and excellent long-term stability. Despite being more expensive than thermocouples or thermistors, RTDs offer superior performance in applications where precision and reliability are critical.

Their design, construction, and method of resistance measurement (2-wire, 3-wire, 4-wire) can be tailored to match the specific needs of industrial, laboratory, or commercial environments.