Introduction

In the oil & gas and process industries, Emergency Shutdown (ESD) valves play a critical role in safeguarding personnel, assets, and the environment. Central to the reliable functioning of these ESD valves are solenoid valves, which act as pilot devices to control pneumatic or hydraulic actuators. Despite being small in size, solenoid valves are among the most crucial components in safety instrumented systems (SIS).

This blog explores solenoid valves used in ESD applications—covering types, coil and enclosure ratings, failure modes, applications, selection criteria, and best maintenance practices—with practical examples from the field.

1. What is a Solenoid Valve?

A solenoid valve is an electromechanically operated valve that controls the flow of a fluid (gas or liquid) when energized. It uses an electromagnetic solenoid coil to actuate a plunger or piston, opening or closing the valve.

In ESD applications, solenoid valves are pilot valves that control the supply or exhaust of air to actuators (typically spring-return types) which drive the final control element—usually an on-off valve.

2. Importance of Solenoid Valves in ESD Systems

Fast Response: Solenoid valves ensure rapid actuation (<1 second) of ESD valves during trip conditions.

Remote Operation: Enables centralized control from Safety PLCs or manual shutdown panels.

Fail-Safe Operation: Designed to de-energize on power loss, causing the ESD valve to move to its fail-safe position (typically fail-close).

Integration with SIS: Usually driven by logic solvers in SIL-rated systems (per IEC 61511).

3. Types of Solenoid Valves Used in ESD Applications

a. Direct-Acting Solenoid Valve

The solenoid directly moves the valve mechanism.

Ideal for low-flow applications and quick response times.

Common in single-acting actuators.

b. Pilot-Operated Solenoid Valve

Uses line pressure to assist in opening the valve.

Suited for larger actuators with higher flow demands.

Typically slower than direct-acting.

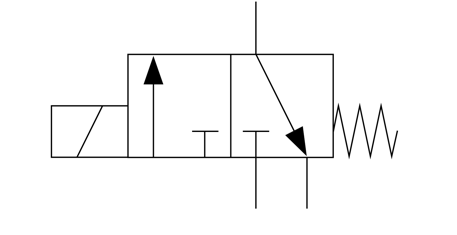

c. 3/2-Way Solenoid Valve

3 ports and 2 positions: Commonly used in spring-return actuators.

De-energized: Exhausts air, actuator moves to fail-safe.

Energized: Allows air supply to actuator.

d. 5/2-Way Solenoid Valve

For double-acting actuators with no spring-return.

Two outputs to control extend/retract motion.

Both positions need air supply for motion.

e. Redundant Solenoid Valve (RSV)

Used in high-SIL or critical applications.

Dual solenoids ensure that valve still actuates if one fails.

4. Construction and Working Principle

Basic Components:

Solenoid Coil: Converts electrical energy into magnetic force.

Plunger/Armature: Moves to open/close the orifice.

Body: Houses the ports and flow paths.

Seals and Springs: Provide sealing and fail-safe return motion.

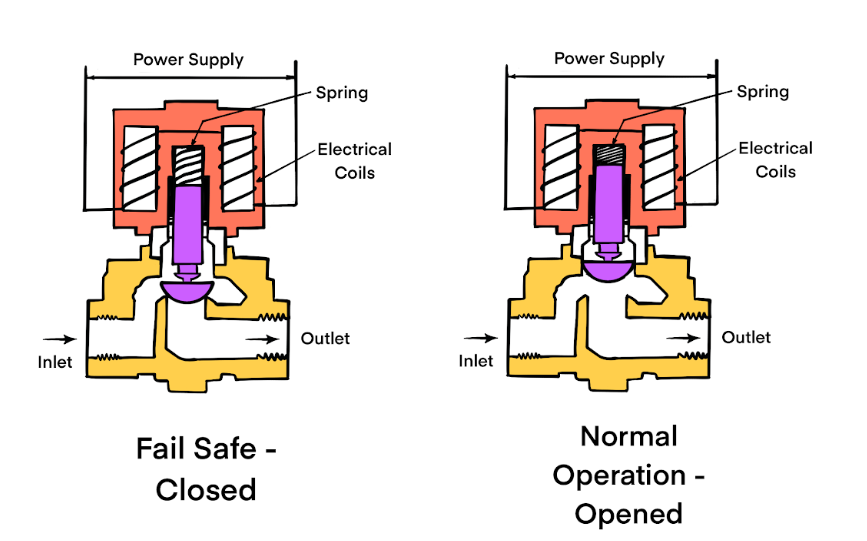

Operation:

Energized: The coil pulls the plunger, changing port connectivity to allow pressurized air to actuator.

De-Energized: Spring returns the plunger to its default (fail-safe) position, usually venting air.

5. Solenoid Coil Ratings and Specifications

a. Voltage Ratings

Common: 24 VDC, 110/230 VAC

Must match the control panel output.

b. Power Consumption

Typical: 5 to 10 Watts

Important for sizing UPS and output modules.

c. Duty Cycle

Continuous duty rated for ESD applications.

d. Inrush and Holding Current

Inrush current may be higher (AC coils).

Must consider in DCS/PLC output design.

e. Enclosure Ratings

IP66/IP67: For water/dust protection.

Explosion-proof (Ex d) or Intrinsically Safe (Ex i) for hazardous areas per ATEX/IECEx.

NEMA Ratings (NEMA 4X, NEMA 7): For North America.

f. Ambient Temperature Ratings

Typically from -40°C to +60°C

Critical for arctic or desert installations.

6. Applications of Solenoid Valves in Oil & Gas and Process Plants

a. Emergency Shutdown (ESD) Valves

Fast shutdown during overpressure, fire, gas leak, or manual activation.

b. Blowdown Systems

Rapid depressurization of process segments.

c. Fire & Gas Systems

Valve actuation upon gas detection or flame signal.

d. Safety Interlocks

Prevent unsafe startups by ensuring valves are in correct positions.

e. HIPPS (High Integrity Pressure Protection Systems)

Used in safety instrumented functions to isolate high-pressure sections.

f. Burner Management Systems

Solenoids control fuel shut-off valves during trips or purging.

7. Selection Criteria for Solenoid Valves

a. Functionality

Choose 3/2-way for spring-return actuators.

Choose 5/2-way for double-acting actuators.

b. Fail-Safe Action

De-energized state must move valve to safe position.

For safety, solenoids are usually “energize to open”.

c. Flow Capacity (Cv or Qn)

Must supply enough air to actuator quickly.

d. Compatibility

Media: Air, nitrogen, or other inert gases.

Port size (1/4”, 1/2”) must match actuator specs.

e. Electrical Compatibility

Must match PLC output: voltage, type (relay/solid-state), power.

f. Certifications

SIL capability (certified per IEC 61508/61511).

Explosion-proof/IS for hazardous area compliance.

g. Environmental Durability

Enclosure, temperature, vibration and corrosion resistance (SS body, epoxy-coated).

8. Installation Best Practices

Mounting Orientation: Follow manufacturer guidelines; usually vertical for gravity-assisted fail-safe.

Manual Override: Helps in commissioning and manual testing.

Surge Protection: Install surge arresters on solenoid lines.

Filter-Regulator-Lubricator (FRL): Clean, dry air improves longevity.

Proximity to Actuator: Minimize tubing length for faster response.

Use of Quick Exhaust Valves: Reduces actuator closing time.

9. Common Failure Modes and Diagnostics

a. Coil Burnout

Due to overvoltage, heat, or moisture ingress.

b. Plunger Sticking

Caused by rust, contamination, or worn seals.

c. Incorrect Wiring

Leads to erratic actuation or constant failure.

d. Exhaust Blockage

Causes actuator to fail to vent, preventing proper shutdown.

e. Internal Leakage

Valve fails to seal properly—compromises fail-safe action.

10. Preventive Maintenance Practices

a. Periodic Testing (Partial Stroke Tests)

Verifies solenoid functionality without full valve actuation.

b. Function Testing

Perform full loop checks during shutdowns.

c. Visual Inspection

Check for corrosion, dust ingress, cable integrity.

d. Clean Air Supply

Monitor air quality regularly.

e. Spare Coil Storage

Keep spares in dry, sealed containers.

f. Manufacturer’s Recommendations

Follow OEM interval-based maintenance (6-month, 1-year, etc.)

11. Real-World Insights and Best Practices

Case 1: Offshore Platform in North Sea

Issue: Solenoid valve failed due to coil insulation breakdown from saltwater ingress.

Solution: Upgraded to SS316 body with IP68-rated coil and added weatherproof junction box.

Case 2: Refinery in Middle East

Issue: Actuator slow to move to fail-safe.

Root Cause: Solenoid mounted far from actuator with long tubing.

Solution: Mounted closer, used quick exhaust valve, improved trip response from 4s to <1.5s.

Case 3: LNG Terminal

Issue: Nuisance trips from solenoid chatter.

Root Cause: PLC output relay bouncing due to low coil resistance.

Solution: Installed flyback diode and solid-state relay for better coil control.

12. Future Trends and Smart Solenoid Valves

Diagnostic Feedback: Solenoids with feedback on position, coil health, or voltage.

Wireless Diagnostics: Real-time alerts on failure.

Integration with IIoT: Solenoids as part of predictive maintenance systems.

Energy-Efficient Coils: Low-power consumption and reduced heat buildup.

Redundancy and Voting Solenoids: To meet SIL 3/4 safety integrity.

Conclusion

Solenoid valves are unsung heroes in ESD systems across oil & gas and process industries. Their selection, installation, and maintenance significantly impact the performance and reliability of safety systems. By understanding coil ratings, valve types, and environmental factors, engineers can ensure safe plant operation under the most demanding conditions.

With technological advancements and growing focus on predictive maintenance and safety, smart solenoid valves are paving the way for next-generation safety systems.

References

IEC 61511: Functional Safety – SIS in the Process Industry

API RP 553: Refinery Control Valves

Manufacturers: ASCO, Rotork, Parker, Emerson, Burkert, Siemens

NAMUR NE43 & NE44 Guidelines