A Hazard and Operability (HAZOP) study is a cornerstone of process safety management, and for an Instrument & Control (I&C) Engineer, it’s not a meeting you just show up for. Your role is pivotal. You’re the gatekeeper of the automated systems, the alarms, and the safety-instrumented functions that act as the primary lines of defense against catastrophic failures. Thorough preparation isn’t just about looking competent; it’s about ensuring the facility’s safety, integrity, and operability. Being unprepared means you risk overlooking critical failure scenarios, misjudging the effectiveness of safeguards, and ultimately, compromising the entire safety review process.

This guide provides a comprehensive checklist and detailed breakdown of the activities and preparations an Instrument Engineer must undertake before walking into that HAZOP workshop.

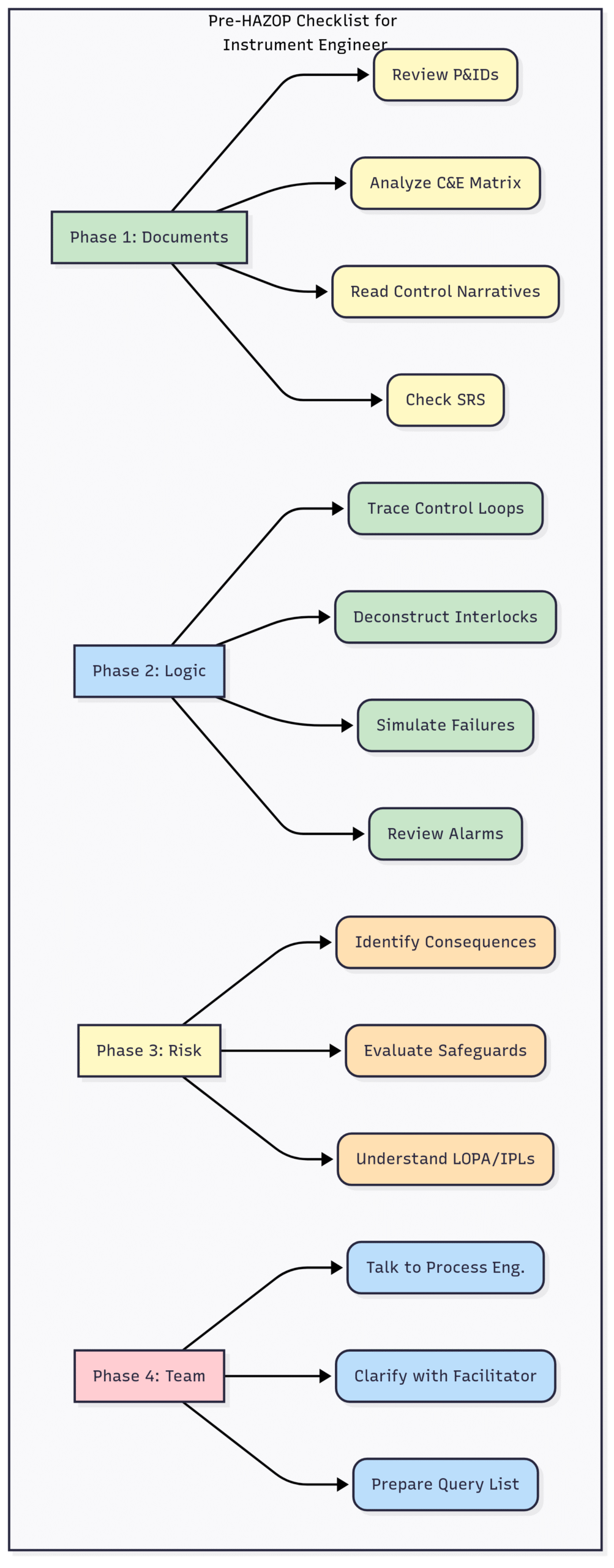

Phase 1: The Document

Before you can analyze risks, you must understand the system inside and out. The first phase of your preparation is an intensive review of all relevant documentation. Your goal is to build a mental model of the process and its control systems. Don’t just read; critically analyze.

Key Documents Checklist:

Piping and Instrumentation Diagrams (P&IDs): This is your bible. Don’t just glance at it. Trace every single line associated with your instrumentation.

Action: Identify all instruments, their tags, and their physical locations. Note the connections to the control system (e.g., DCS, PLC, SIS).

Look For: Inconsistencies between different drawings, missing instrument bubbles, unclear loop connections, and incorrect I/O designations. Pay special attention to the fail-safe positions of control valves (Fail Open, Fail Close, Fail Last).

Cause & Effect (C&E) Matrix: The C&E, or Safety Logic Diagram, is a direct input to your analysis. It maps out the automatic responses to abnormal conditions.

Action: Correlate the C&E with the P&IDs. For every cause listed (e.g., High Pressure in a vessel), trace the corresponding effect (e.g., a valve closing, a pump tripping).

Look For: Logic that seems counter-intuitive, missing causes that could lead to a hazard, or effects that don’t adequately mitigate the risk. Question the trip setpoints and ensure they provide sufficient time for action before a hazardous event occurs.

Control & Operating Narratives/Philosophy: These documents explain the why behind the control strategy. They describe how the plant is intended to be operated during startup, normal operation, and shutdown.

Action: Read these documents to understand the overall control philosophy. How are loops tuned? What are the key operator actions? What are the sequences for complex operations?

Look For: Ambiguities in operator instructions, conflicts between the narrative and the P&IDs/C&E, and assumptions about system performance that may not be realistic.

Safety Requirement Specification (SRS): For any Safety Instrumented Function (SIF), the SRS is the defining document. It’s the design specification for your most critical safety layers.

Action: For every SIF identified, review its SRS in detail. Understand the required Safety Integrity Level (SIL), the process safety time, the test intervals, and the specific functional logic.

Look For: Any SIF without a defined SRS is a major red flag. Check if the design described in other documents (like the C&E) truly meets the requirements laid out in the SRS.

Vendor Documentation: Your control systems, valves, and instruments all come with their own manuals, specifications, and limitations.

Action: Familiarize yourself with the operating principles and, crucially, the failure modes of the specific hardware being used. What happens when a smart transmitter loses power? How does the digital valve controller diagnose a fault?

Look For: Specific failure rates (if available), diagnostic coverage, and any operational limitations that might impact the HAZOP discussion.

Previous HAZOP/LOPA Reports: If this is a re-HAZOP or a brownfield project, the reports from previous studies are gold mines of information.

Action: Review past recommendations, especially those assigned to the I&C discipline. Were they implemented correctly? Why were certain decisions made?

Look For: Previously identified hazards that might still be relevant, and understand the rationale for safeguards that were accepted or rejected in the past.

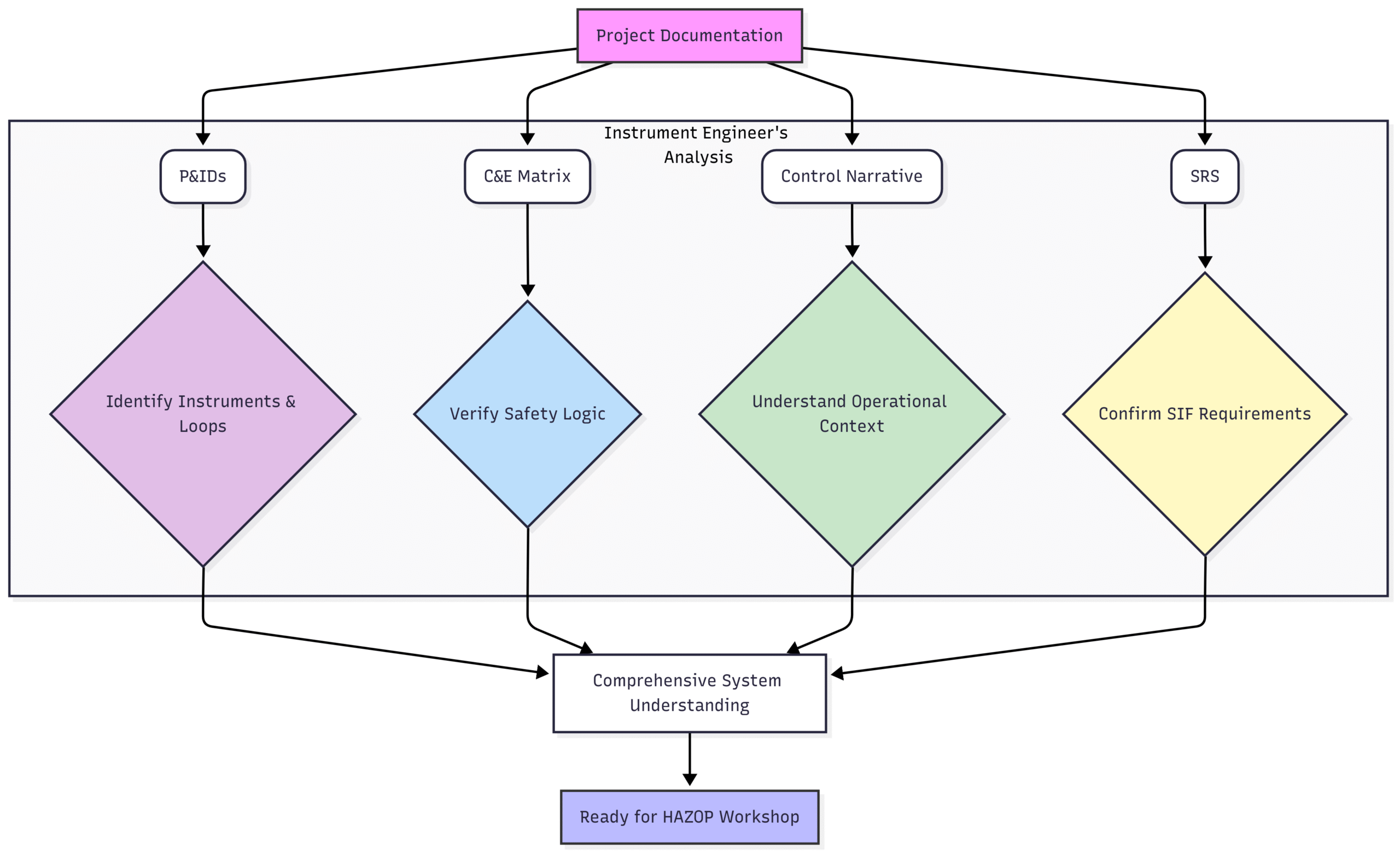

Here’s how the information flows into your preparation:

Phase 2: Mastering the System & Logic

With the documents reviewed, it’s time to connect the dots and master the functional logic. This phase is about moving from a static understanding of the drawings to a dynamic understanding of how the system behaves in real-time.

Key Activities Checklist:

Trace Control Loops End-to-End: For every critical control loop (e.g., pressure, temperature, level, flow), mentally trace its entire path.

Action: Start at the sensor (e.g., pressure transmitter). Follow the signal to the input card of the control system (DCS/PLC). Understand how the controller block processes this signal based on its setpoint. Follow the output signal to the final control element (e.g., control valve with an I/P converter).

Be Prepared to Answer: “What happens if this transmitter fails high/low/drifts?” “What is the fail-safe position of this valve and why?” “Can the operator take manual control of this loop? If so, how?”

Deconstruct Interlocks and Permissives: Interlocks are automated safety actions, while permissives are conditions that must be met before an action can be taken (e.g., starting a pump). They are the core of automated safety.

Action: Use the C&E and P&IDs to list all key interlocks. For each one, identify the initiating cause, the logic solver (e.g., SIS PLC), and the final element it acts upon.

Be Prepared to Answer: “What is the purpose of this interlock?” “Can it be bypassed? If so, who has the authority, and is it alarmed?” “What happens if the sensor for this interlock fails?”

Simulate Failure Modes: The HAZOP process will systematically apply guide words (e.g., NO, MORE, LESS) to process parameters. Your job is to translate these into instrument failure modes.

Action: Go through your instrument list and consider the consequences of common failures for each device type:

Transmitter: Fails high, fails low, drifts, frozen/last value.

Control Valve: Fails open, fails closed, fails in last position, sticks.

Solenoid Valve: Fails to energize, fails to de-energize.

Controller (DCS/PLC): Freezes output, goes to manual, fails completely.

Power Supply: Loss of power to instrument, I/O card, or controller.

Be Prepared to Answer: “If the level transmitter for the separator fails low, what happens? Does the outlet valve close? Does the inlet valve open? Is there an alarm? Will this lead to an overfill?”

Review Alarm Philosophy and Rationalization: Alarms are critical independent protection layers, but only if they are managed correctly. An alarm flood can be as dangerous as no alarm at all.

Action: Check the alarm setpoints. Are they meaningful? Do they give the operator enough time to react? Review the alarm priorities. Is a high-priority alarm truly critical, or is it just a nuisance?

Be Prepared to Answer: “What is the alarm setpoint for high temperature?” “How much time does the operator have to respond between the alarm and a potential trip or hazardous event (process safety time)?” “Is this alarm configured to be suppressed during startup?”

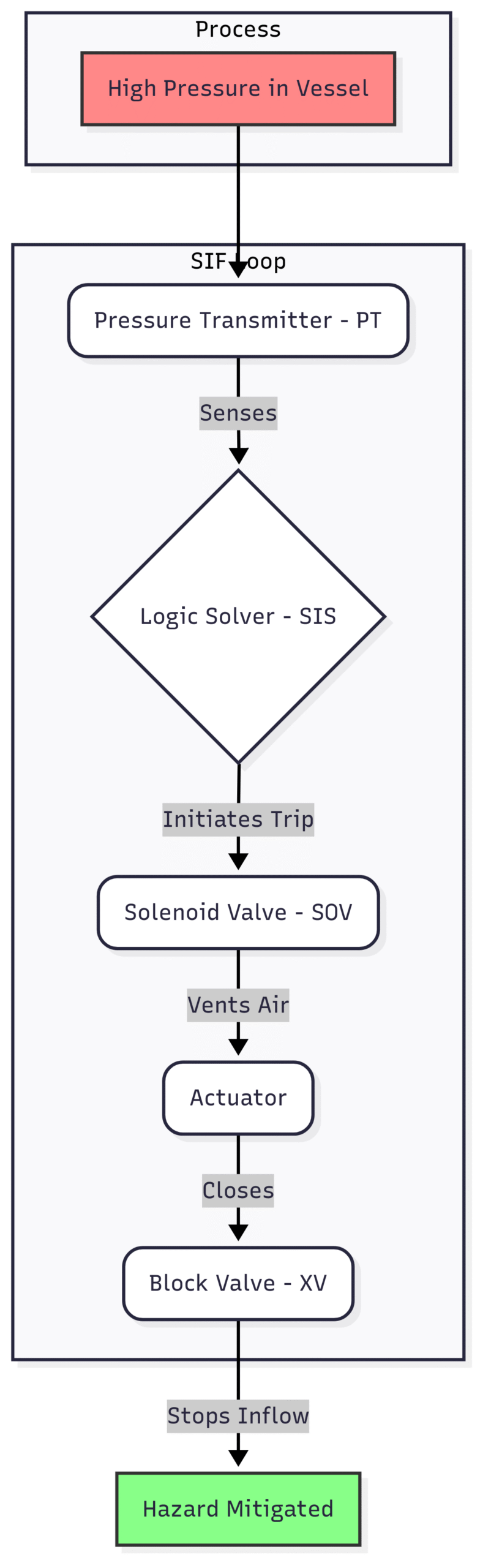

A simplified Safety Instrumented Function (SIF) loop is a good mental model to keep in mind.

Phase 3: Consequence, Safeguarding, and Protection Layers

Now you combine your understanding of the system with a risk-based mindset. In this phase, you anticipate the discussions about consequences and evaluate the strength of the safeguards you are responsible for.

Key Activities Checklist:

Pre-emptively Identify Consequences: For each control loop and interlock, think about what could go wrong if it fails. Don’t wait for the team to ask.

Action: Think through the chain of events. A failed level controller could lead to overfill. What does that mean? A spill? Release of toxic gas? Over-pressurization of a downstream vessel?

Be Prepared to Answer: “If the cooling water control valve fails closed, what is the ultimate consequence? Is it just a loss of production, or could it lead to a runaway reaction?”

Evaluate Existing Safeguards: A safeguard is a device, system, or action that can prevent a hazardous scenario from developing or mitigate its consequences. Your instruments are often the primary safeguards.

Action: For each potential failure, list the safeguards in place. Classify them. Is it part of the Basic Process Control System (BPCS)? Is it an operator alarm? Is it a hard-wired SIF? Is it a mechanical device like a pressure relief valve (PSV)?

Be Prepared to Answer: “The operator has a low-level alarm. Is that a sufficient safeguard against pump damage from running dry? Or do we need an automatic low-level trip?”

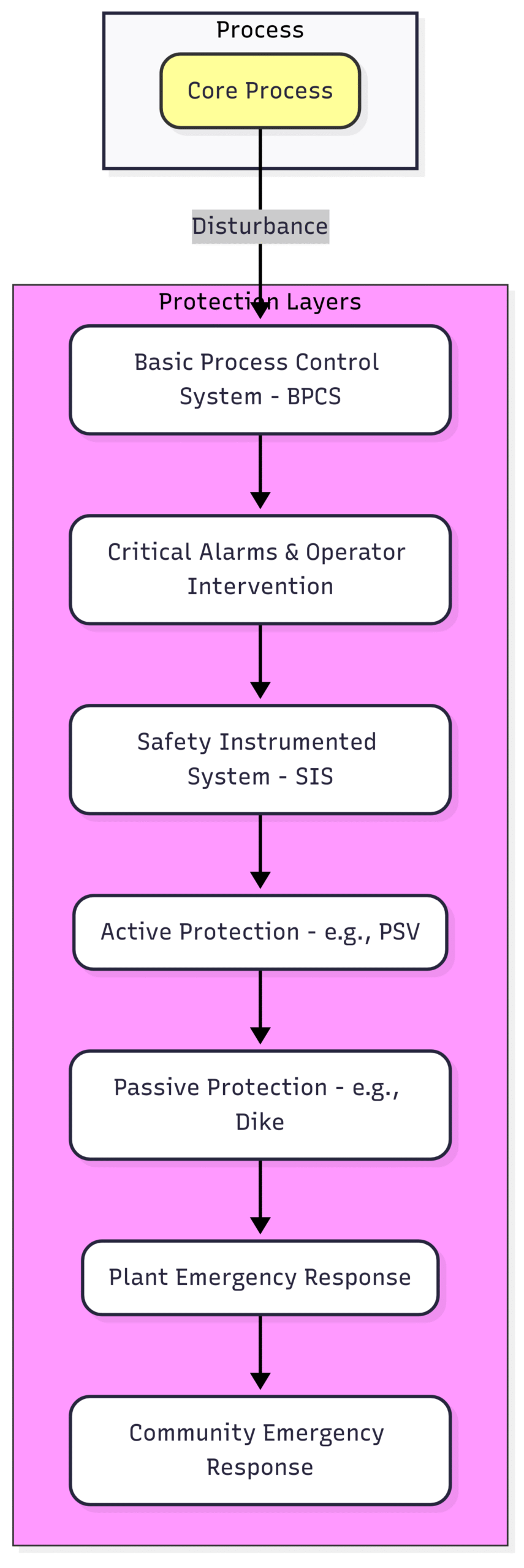

Understand Layers of Protection Analysis (LOPA): While HAZOP is qualitative, it’s often followed by LOPA, which is semi-quantitative. Understanding LOPA principles is crucial. You need to know what constitutes a valid Independent Protection Layer (IPL).

Action: Familiarize yourself with the “onion skin” model of protection layers. An IPL must be:

Specific: It is designed to prevent a specific hazard.

Independent: Its effectiveness doesn’t depend on the initiating event or any other layer of protection.

Dependable: It can be relied upon to work when required.

Auditable: It can be tested and validated.

Be Prepared to Answer: “Is the BPCS control loop that manages pressure a valid IPL against a high-pressure event? (Usually no, as it’s active and its failure could be the cause). Is the high-pressure alarm a valid IPL? Is the high-high pressure SIF trip a valid IPL? Is the PSV a valid IPL?”

The LOPA “onion” is a powerful concept to visualize this.

Phase 4: Collaboration and Final Checks

Safety is a team sport. Your individual preparation is vital, but so is your pre-workshop alignment with other key disciplines.

Final Preparation Checklist:

Talk to the Process Engineer: The Process Engineer owns the process. They understand the chemistry, thermodynamics, and operational risks better than anyone.

Action: Sit down with them before the HAZOP. Walk through the P&IDs together. Ask them: “What are you most worried about in this part of the plant?” “Which parameters are the most critical to control?” This gives you invaluable insight into where to focus your attention.

Clarify Doubts with the HAZOP Facilitator: The facilitator is your guide for the workshop. Don’t be afraid to approach them beforehand.

Action: If you’re unsure about the scope of a specific HAZOP node or have questions about the methodology, ask. It’s better to clarify now than to derail the meeting later.

Prepare a Personal “Query & Action List”: As you go through your preparation, you will inevitably find issues, inconsistencies, or areas of concern.

Action: Keep a running list. It might include things like:

“P&ID rev 3 shows FIC-101 as Fail Close, but C&E rev 2 implies Fail Open. Which is correct?”

“No cause listed on C&E for pump P-101 motor overload. Should this trip the pump?”

“Confirm test frequency for SIF-203 with the SRS.”

This list not only helps you get answers but also demonstrates your diligence and becomes a list of action items to raise during the HAZOP.

Conclusion: Preparation is Protection

Walking into a HAZOP workshop as an Instrument Engineer without this level of preparation is a disservice to your team, your company, and the principles of process safety. By immersing yourself in the documentation, mastering the control logic, thinking like a risk assessor, and collaborating with your peers, you transform from a passive participant into a vital contributor.

Thorough preparation allows you to confidently and accurately answer questions, propose effective safeguards, and challenge assumptions. It ensures that the safety systems you are responsible for are correctly represented, robustly designed, and capable of protecting the plant when it matters most. Your diligence before the workshop is a direct investment in a safer future.

For a final, quick reference, use this checklist:

- The Ultimate HAZOP Preparation Checklist for Instrument Engineers (2025)

- HAZOP Checklist: 25 Essential Preparation Steps for Instrument & Control Engineers

- Don’t Attend a HAZOP Unprepared: Your Essential Instrument Engineer Checklist

- A Complete Guide to HAZOP Preparation for the Instrument Engineer

- Mastering the HAZOP: A Deep Dive for Instrument & Control Engineers

- HAZOP for Instrument Engineers: From P&ID Review to Final Checks

- How to Prepare for a HAZOP Workshop: An Instrument Engineer’s Guide

- Maximizing Your Impact in a HAZOP: A Preparation Guide for I&C Engineers

- The Instrument Engineer’s Role in HAZOP: A Complete Preparation Strategy

10. Process Safety and HAZOP: Key Preparations for Instrumentation Professionals