In the industrial processes, where precision and reliability are paramount, the control valve plays a leading role. This fluid control systems is responsible for regulating the flow, pressure, temperature, and level of liquids and gases, ensuring operational stability, safety, and efficiency. However, with a myriad of options available, selecting the right control valve can be a daunting task. A suboptimal choice can lead to process inefficiencies, increased maintenance costs, and even catastrophic failures.

This comprehensive guide will walk you through the top 10 factors to consider when selecting a control valve, empowering you to make an informed decision that optimizes your process and safeguards your operations. We will delve into the critical aspects, from understanding the fluid’s properties to selecting the appropriate actuator, and provide you with the knowledge to choose a valve that is not just a component, but a cornerstone of your system’s success.

1. Fluid Characteristics: The Heart of the Matter

The first and most fundamental consideration in control valve selection is the nature of the fluid it will be controlling. The properties of the process fluid dictate the required materials of construction, the valve’s design, and its overall suitability for the application.

Key Fluid Properties to Analyze:

- State: Is the fluid a liquid, gas, or a multiphase mixture? The state will significantly influence the valve’s sizing and capacity calculations.

- Corrosivity: An aggressive or corrosive fluid will necessitate the use of specialized materials like stainless steel, exotic alloys (e.g., Hastelloy, Monel), or lined valves to prevent premature failure.

- Erosivity: Fluids containing solid particles, such as slurries, can cause erosion of the valve’s internal components. In such cases, hardened trim materials or valves with a straight-through flow path, like a ball or butterfly valve, may be more suitable than a globe valve.

- Viscosity: Highly viscous fluids require larger port sizes and may necessitate more powerful actuators to overcome the increased operational torque.

- Temperature and Pressure: The operating temperature and pressure ranges are critical for selecting materials that can withstand the process conditions without degradation.

2. Sizing and Flow Coefficient (Cv): Ensuring Optimal Performance

Proper valve sizing is crucial for achieving precise control. An undersized valve will not be able to pass the required flow, creating a bottleneck in the process. Conversely, an oversized valve will be forced to operate at a very low percentage of its opening, leading to poor control, instability, and potential damage from “chattering.”

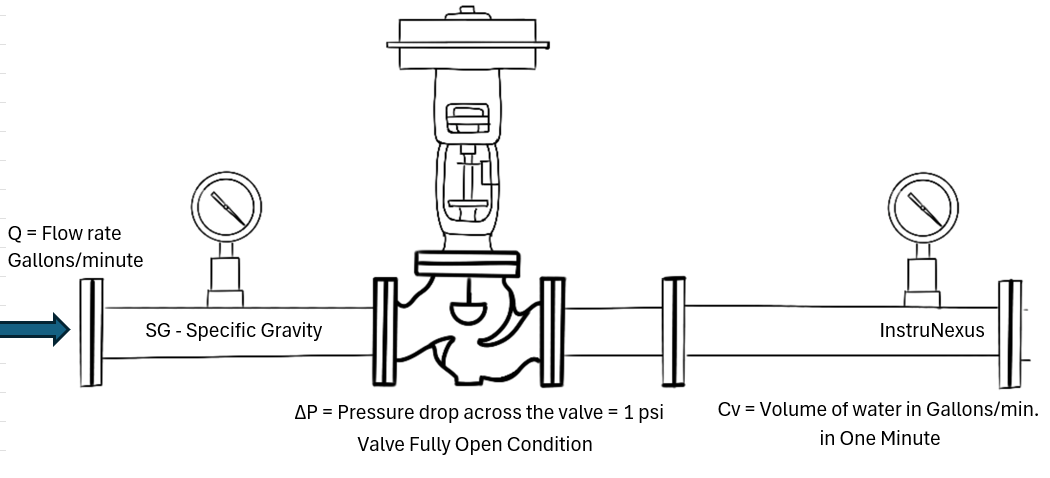

The key parameter in valve sizing is the Flow Coefficient (Cv), which represents the valve’s capacity for fluid to flow through it. It is defined as the number of US gallons of water per minute at 60°F that will pass through a valve with a pressure drop of one psi.

Sizing Considerations:

- Calculate the required Cv for minimum, normal, and maximum flow conditions.

- Select a valve where the calculated Cv falls within the controllable range of the valve, typically between 20% and 80% of its total capacity.

- Avoid the “line size is the right size” fallacy. The control valve is often smaller than the pipeline to ensure adequate pressure drop and control authority.

3. Pressure Drop (Delta P): The Driving Force of Control

The pressure drop across the control valve is the driving force that enables it to regulate the flow. Without an adequate pressure differential between the inlet and outlet, the valve loses its ability to control the process.

Key Aspects of Pressure Drop:

- Sufficient Pressure Drop: Ensure there is enough pressure drop available at all flow conditions to allow the valve to function effectively.

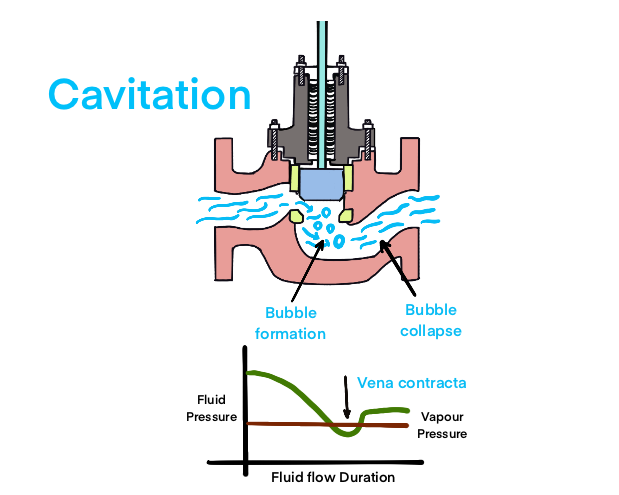

- Flashing and Cavitation: In liquid applications, a high pressure drop can lead to the fluid’s pressure falling below its vapor pressure, causing it to flash into vapor. If the pressure recovers downstream, these vapor bubbles can collapse violently, a phenomenon known as cavitation. Both flashing and cavitation can cause severe damage to the valve and downstream piping.

- Noise: In gas applications, high pressure drops can generate excessive noise, which can be a safety hazard and a sign of inefficient energy dissipation.

4. Flow Characteristic: Tailoring the Response

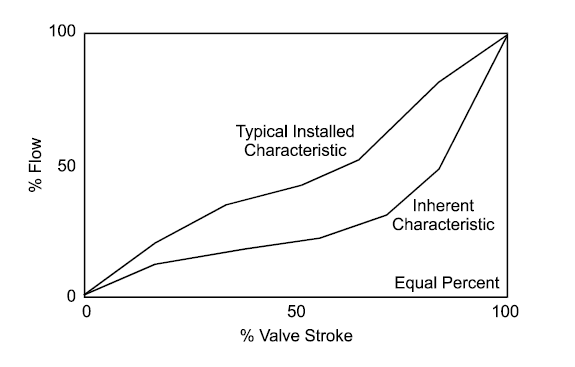

The flow characteristic of a control valve describes the relationship between the valve’s travel (the degree to which it is open) and the flow rate through it, assuming a constant pressure drop. The three primary inherent flow characteristics are:

- Linear: The flow rate is directly proportional to the valve travel. This is ideal for applications where the pressure drop across the valve is relatively constant.

- Equal Percentage: Equal increments of valve travel produce an equal percentage change in the existing flow rate. This characteristic is well-suited for applications with significant variations in pressure drop and provides fine throttling control at low flow rates.

- Quick Opening: A large increase in flow occurs with a small initial opening of the valve. These valves are typically used for on/off or relief services.

The installed flow characteristic considers the interaction of the valve with the entire system, including pumps and piping, which can alter the inherent characteristic.

5. Valve Type and Construction: Form Follows Function

The physical design of the control valve is a critical factor that influences its performance, maintenance requirements, and suitability for a given application. The most common types include:

- Globe Valves: Known for their excellent throttling capabilities and tight shut-off. They are ideal for precise flow control but have a higher pressure drop.

- Ball Valves: Offer a straight-through flow path, resulting in low pressure drop and high capacity. They are well-suited for on/off and throttling applications, particularly with clean fluids.

- Butterfly Valves: A cost-effective option for larger pipe sizes, offering good throttling control and low pressure drop. High-performance butterfly valves can handle a wide range of temperatures and pressures.

- Diaphragm Valves: Ideal for corrosive and erosive fluids as the diaphragm isolates the process fluid from the valve’s operating mechanism.

- Pinch Valves: Excellent for slurries and abrasive fluids, providing a straight-through flow path and tight shut-off.

6. Material Selection: Withstanding the Elements

The choice of materials for the valve body, trim (the internal components in contact with the fluid), and seals is paramount for ensuring longevity and preventing leaks.

Material Selection Considerations:

- Body Material: Must be compatible with the process fluid’s corrosivity, temperature, and pressure. Common materials include carbon steel, stainless steel, and various alloys.

- Trim Material: The trim components (seat, plug, stem) are subject to high velocities and potential erosion and corrosion. Hardened materials like Stellite or ceramics may be necessary for severe service applications.

- Seal Material: The packing and gaskets must be compatible with the fluid and operating temperature to prevent fugitive emissions. Options range from standard elastomers to advanced polymers like PTFE and graphite.

7. Actuator Selection: The Power Behind the Throne

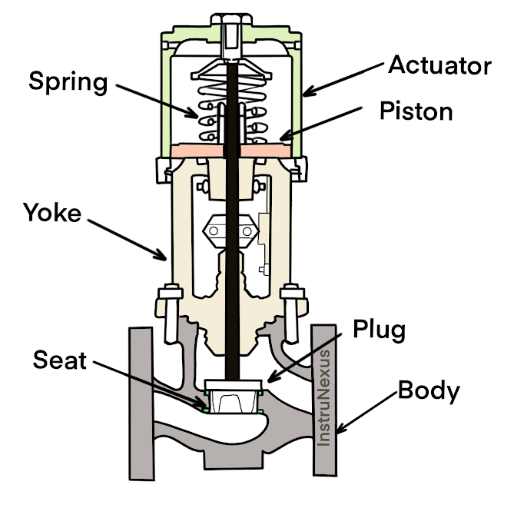

The actuator is the powerhouse of the control valve, providing the force needed to open and close it. The choice of actuator depends on the required thrust, speed of operation, available power source, and fail-safe requirements.

Common Actuator Types:

- Pneumatic Actuators: The most common type, using compressed air to generate motion. They are reliable, cost-effective, and can be easily configured for fail-safe operation (fail-open or fail-close).

- Electric Actuators: Use an electric motor to position the valve. They offer precise positioning and are ideal for remote applications where compressed air is not available.

- Hydraulic Actuators: Utilize hydraulic fluid to generate very high thrust, making them suitable for large valves and high-pressure applications.

Fail-Safe Action: It is critical to determine the desired valve position in the event of a power failure. Should the valve fail open to prevent over-pressurization, or fail close to stop the flow of a hazardous material?

| Feature | Pneumatic Actuators | Electric Actuators |

| Power Source | Compressed Air | Electricity (AC or DC) |

| Speed | 💨 High-speed operation, ideal for quick cycling. | 🐢 Variable and controllable speed, but generally slower than pneumatic. |

| Cost | 💰 Lower initial cost for the actuator itself. | 💸 Higher initial cost, but can offer lower long-term operating costs. |

| Precision | 🎯 Less precise positioning due to the compressibility of air. | 📍 Highly precise and repeatable positioning and velocity control. |

| Fail-Safe Options | ✅ Simple and cost-effective spring-return mechanisms are common. | ⚙️ More complex and costly, often requiring batteries or supercapacitors. |

| Force/Torque | 💪 High force and torque in a compact size. | 🦾 Good force and torque, but larger and heavier for the same output. |

| Energy Efficiency | 📉 Lower energy efficiency due to air leaks and compressor energy consumption. | ⚡️ Higher energy efficiency as they only consume power on demand. |

| Operating Environment | 🌡️ Can operate in a wide range of temperatures and hazardous environments. | ⚠️ More sensitive to high temperatures, moisture, and flammable atmospheres. |

| Maintenance | 🛠️ Requires maintenance of the compressed air system (filters, regulators, lubricators). | 🔌 Lower maintenance requirements, primarily focused on the motor and gearbox. |

| Complexity | Simple design and operation. | More complex with integrated electronics and controls. |

8. End Connections: Ensuring a Secure Fit

The end connections of the control valve determine how it will be integrated into the pipeline. The choice depends on the pressure rating, piping standards, and maintenance requirements.

Common End Connection Types:

- Flanged: The most common type, providing a secure and leak-tight connection that is easy to install and remove for maintenance.

- Screwed (Threaded): Typically used for smaller valves in low-pressure applications.

- Welded: Offer a permanent, leak-proof connection, ideal for high-pressure and high-temperature applications where no leakage can be tolerated.

- Wafer and Lug: Common for butterfly valves, designed to be sandwiched between two pipe flanges.

9. Rangeability and Turndown: Measuring Control Flexibility

Rangeability is an inherent characteristic of the valve that describes the ratio of its maximum controllable flow to its minimum controllable flow. A higher rangeability indicates a wider operating range.

Turndown, on the other hand, is the ratio of the maximum required flow in a specific application to the minimum controllable flow. It is a measure of the installed performance of the valve.

Why are they important?

- A valve with a high rangeability can effectively control the process over a wide range of operating conditions.

- Ensuring the required turndown of the application is within the rangeability of the selected valve is crucial for maintaining control at all process loads.

10. Standards, Certifications, and Maintenance: Long-Term Reliability

Finally, it is essential to consider the applicable industry standards and certifications, as well as the long-term maintenance requirements of the valve.

Key Considerations:

- Industry Standards: Ensure the valve complies with relevant standards such as those from the American National Standards Institute (ANSI), the International Society of Automation (ISA), and the American Petroleum Institute (API).

- Certifications: Depending on the application, certifications for fire safety (API 607), fugitive emissions (ISO 15848), or specific industry requirements (e.g., NACE for sour service) may be necessary.

- Maintenance: Consider the ease of maintenance and the availability of spare parts. A valve that is difficult to service can lead to extended downtime and increased operational costs.

Conclusion: A Strategic Decision for a Stable Process

Selecting the right control valve is not merely a matter of picking a component off a shelf. It is a strategic decision that requires a thorough understanding of your process, a careful evaluation of the available options, and a long-term perspective on performance and reliability. By systematically considering these ten critical factors, you can move beyond a simple purchase and make an investment that will pay dividends in the form of a stable, efficient, and safe process for years to come. Remember, the right control valve is the silent partner in your operational success.