Control Valve Phenomena Explained

An interactive guide to Cavitation, Flashing, and Choked Flow in the Oil & Gas and Process Industries.

1. Introduction to Control Valves

Control valves are critical components for regulating fluid flow in industries like oil & gas, chemical processing, and power generation. They act like adjustable gates, precisely controlling the flow rate of liquids, gases, or steam based on signals from a control system (like a DCS or SCADA). However, when high pressure drops or velocities occur across a valve, it can lead to damaging phenomena. This guide explores three of the most common issues: cavitation, flashing, and choked flow.

Interactive Flow Simulator

Normal Flow

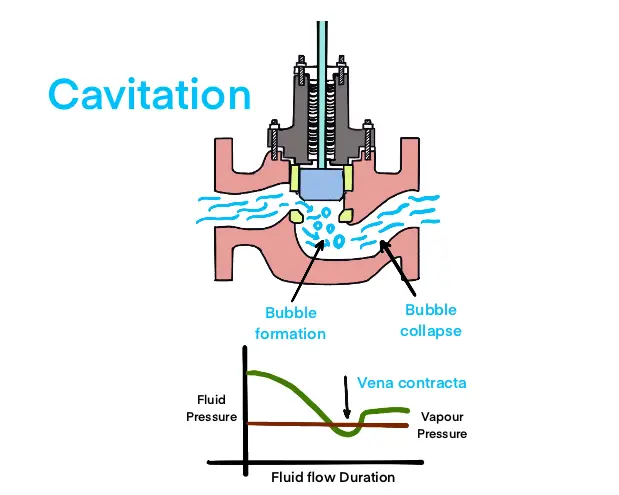

2.1 What is Cavitation?

Cavitation occurs when a liquid's pressure drops below its vapor pressureThe pressure at which a liquid turns into a vapor at a given temperature., causing vapor bubbles to form. As these bubbles move downstream to a higher pressure zone, they collapse violently. This implosion creates micro-jets and shockwaves that are highly destructive to valve components.

Causes

- Large pressure drop across the valve.

- High inlet pressure, low outlet pressure.

- Fluid velocity increases at the valve's narrowest point (vena contracta).

- Using fluids with relatively high vapor pressures (e.g., hot water).

Effects

- Severe Damage: Erosion, pitting, and fatigue on valve trim and body.

- Noise & Vibration: Creates a loud, gravel-like noise and high-frequency vibrations.

- Performance Loss: Unstable flow, reduced valve capacity, and poor process control.

Prevention & Solutions

- Manage Pressure Drop: Use multiple valves in series or pressure-reducing devices.

- Anti-Cavitation Trim: Select valves with multi-stage trims that drop pressure gradually.

- Increase Back Pressure: Ensure outlet pressure remains well above the fluid's vapor pressure.

- Proper Sizing: Avoid oversized valves which can create excessive pressure drops.

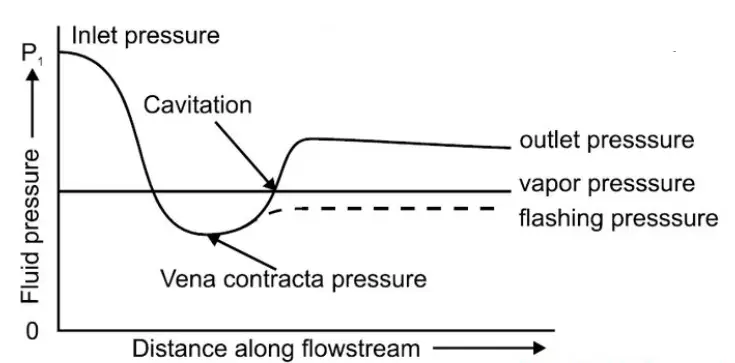

3.1 What is Flashing?

Flashing is similar to cavitation but occurs when the outlet pressure (P2) remains below the fluid's vapor pressure (Pv). Instead of forming and collapsing, the vapor bubbles remain and the fluid exits the valve as a two-phase mixture of liquid and vapor. This high-velocity, two-phase flow is highly erosive.

Causes

- Outlet pressure is significantly lower than the fluid's vapor pressure.

- High fluid temperature, which lowers its vapor pressure.

- Large pressure drops into a low-pressure vessel or line.

Effects

- Erosion: The high-velocity vapor/liquid mix acts like sandblasting, causing smooth, polished wear on valve surfaces.

- Noise: Produces a loud, distinct hissing or rushing sound.

- Reduced Capacity: The large volume of vapor can choke the valve, limiting flow.

- Control Issues: Unpredictable flow control due to the two-phase nature.

Prevention & Solutions

- Increase Outlet Pressure: Raise downstream pressure to stay above the vapor pressure.

- Hardened Trim: Use valves with hardened materials (e.g., Stellite, Tungsten Carbide) to resist erosion.

- Angle Valves: Use angle-style valve bodies that allow the flashing mixture to impinge on the downstream piping, not the valve body itself.

- Correct Sizing: Proper sizing is crucial to manage velocity and pressure drop.

4.1 What is Choked Flow?

Choked flow occurs when the fluid velocity at the valve's narrowest point (the vena contractaThe point in a fluid stream where the diameter of the stream is the least, and fluid velocity is at its maximum.) reaches its sonic velocity (the speed of sound in that fluid). Once this happens, the flow rate cannot be increased further, regardless of how much the upstream pressure is increased or the downstream pressure is lowered. The valve is essentially passing the maximum flow it possibly can under those conditions.

Causes

- High Pressure Ratio: A large pressure drop across the valve, especially in gas or vapor service.

- Low Downstream Pressure: Creates the conditions for fluid to accelerate to sonic velocity.

- Flow Restrictions: Inadequate valve or pipe size for the required flow rate.

Effects

- Flow Limitation: The primary effect is that you lose control. Increasing upstream pressure won't increase flow.

- Energy Loss: The system is operating inefficiently.

- System Instability: Can cause instability in processes that require precise flow modulation.

- Noise & Vibration: Can generate significant noise and vibration.

Prevention & Solutions

- Proper Sizing: The most critical factor. The valve must be sized correctly for the specific gas and flow conditions.

- Pressure Regulators: Use downstream regulators to manage pressure and prevent choking conditions.

- High-Capacity Valves: Select valve designs that are inherently better at handling high flow rates without choking.

- Limit Pressure Drop: If possible, design the system to operate with a lower pressure drop across the control valve.

5. Conclusion

Understanding and mitigating cavitation, flashing, and choked flow is essential for the safety, reliability, and efficiency of any process system. These phenomena are not just minor annoyances; they can lead to catastrophic equipment failure, costly downtime, and unsafe operating conditions.

By focusing on proper system design, careful valve selection and sizing, and managing operating pressures, engineers and operators can prevent these issues. This ensures the long-term health of control valves and the stability of the entire process.

Control valves are essential components in the regulation of fluid flows in the oil, gas, and process industries. They help in adjusting the flow rate of fluids within a system, which is critical for optimizing performance and ensuring safety. However, when flow conditions reach certain critical levels, problems like cavitation, flashing, and choked flow can occur, potentially leading to serious damage to the system, reduced performance, and safety hazards.

In this blog, we will delve deep into cavitation, flashing, and choked flow in control valves, explaining their causes, effects, and solutions for the oil & gas and process industries.

1. Introduction to Control Valves and Flow Control

Control valves are designed to regulate the flow of liquids, gases, and steam through pipelines and systems. They are typically located in systems where precise flow control is required, such as chemical plants, power plants, oil & gas facilities, and water treatment plants. These valves operate by adjusting the valve opening based on signals received from the process control system, typically a Distributed Control System (DCS) or a Supervisory Control and Data Acquisition (SCADA) system.

However, the valve’s ability to perform its job can be compromised if the operating conditions result in high velocity or pressure drop across the valve. This can lead to undesirable phenomena such as cavitation, flashing, and choked flow, which need to be understood and managed properly.

2. Cavitation in Control Valves

2.1 What is Cavitation?

Cavitation occurs when the pressure of a fluid drops below its vapor pressure, causing the formation of vapor bubbles inside the fluid stream. When these vapor bubbles are carried downstream into areas of higher pressure, they collapse violently, leading to localized shockwaves and intense energy release. This sudden collapse can cause damage to the valve components, such as the valve trim, body, and seat.

2.2 Causes of Cavitation

The primary cause of cavitation in control valves is a significant pressure drop across the valve, where the pressure in the flow stream falls below the vapor pressure of the fluid. This condition is most commonly found in systems where:

-

The pressure at the valve inlet is high, and the outlet pressure is low.

-

The flow rate is reduced, increasing the velocity of the fluid through the valve.

-

Fluids with low vapor pressures, such as water or hydrocarbons, are involved.

2.3 Effects of Cavitation

Cavitation can have several negative effects on both the control valve and the entire system:

-

Valve Damage: The implosion of vapor bubbles causes erosion, pitting, and fatigue of the valve trim, leading to premature wear and failure.

-

Flow Instability: Cavitation can cause unstable flow and fluctuations in pressure, negatively affecting the process control.

-

Noise and Vibration: Cavitation can generate high-frequency noise and vibrations, which can cause additional mechanical stresses on the valve and other system components.

2.4 Preventing Cavitation

To avoid cavitation, operators can implement several strategies:

-

Reduce Pressure Drop: Ensure that the pressure drop across the valve does not exceed the vapor pressure of the fluid. This can be achieved by selecting the correct valve size or using pressure-reducing devices.

-

Use Anti-Cavitation Valves: These valves are designed with features such as multi-stage trims or cages that reduce the pressure drop gradually, preventing the conditions that lead to cavitation.

-

Incorporate Back-Pressure Regulators: These devices can maintain a minimum pressure at the valve outlet, ensuring that the fluid pressure does not fall below the vapor pressure.

-

Select Proper Valve Size: Oversized valves may cause excessive pressure drops, leading to cavitation. Proper sizing helps in minimizing cavitation risks.

3. Flashing in Control Valves

3.1 What is Flashing?

Flashing is similar to cavitation, but the difference lies in the nature of the phase change of the fluid. While cavitation involves the formation of vapor bubbles that collapse, flashing occurs when the pressure at the valve outlet is reduced so significantly that the liquid instantly vaporizes, turning into gas or vapor as it passes through the valve. The presence of vapor bubbles can lead to rapid changes in the flow characteristics and can result in significant energy loss.

3.2 Causes of Flashing

Flashing is typically caused by:

-

Excessive Pressure Drop: A large pressure drop from a high-pressure liquid to a low-pressure vapor can induce flashing. This occurs when the outlet pressure is significantly lower than the fluid’s vapor pressure.

-

Temperature Effects: Increased temperature of the fluid can lower its vapor pressure, increasing the likelihood of flashing.

-

High Flow Rates: Fast-moving fluids through a control valve may lead to sudden reductions in pressure, facilitating flashing.

3.3 Effects of Flashing

The effects of flashing on control valves and processes are similar to cavitation but can be more severe:

-

Erosion: The rapid phase change and the resulting formation of vapor bubbles can lead to erosion and pitting on the valve surfaces, particularly on trim components.

-

Noise: Flashing causes loud, distinct noises due to the rapid formation of vapor bubbles and their collapse, similar to cavitation.

-

Pressure Fluctuations: Flashing can result in unstable flow conditions, leading to fluctuations in pressure and flow rate.

-

Reduced Flow Control: The presence of vapor reduces the effective area for fluid flow, which can result in less predictable control and poor performance in the process.

3.4 Preventing Flashing

To mitigate flashing, the following methods can be used:

-

Increasing Outlet Pressure: By increasing the pressure downstream of the valve, the likelihood of flashing can be reduced.

-

Using Flashing-Resistant Valves: Some valves are designed with features that minimize the chances of flashing by allowing the vapor to exit in a controlled manner.

-

Install Pressure-Reducing Valves: These can help maintain the required pressure in the system and prevent flashing conditions.

-

Correct Valve Sizing: As with cavitation, proper valve sizing ensures that the pressure drop is within acceptable limits to prevent flashing.

4. Choked Flow in Control Valves

4.1 What is Choked Flow?

Choked flow occurs when the velocity of the fluid at the valve reaches the speed of sound (sonic velocity). When this happens, any further increase in the flow rate is no longer possible, as the flow becomes constrained by the conditions at the valve. The flow rate becomes limited by the valve’s capacity to pass the fluid, and any increase in pressure drop upstream of the valve does not result in a proportional increase in flow.

4.2 Causes of Choked Flow

Choked flow typically occurs in gas systems, particularly in applications involving natural gas, compressed air, or other gases. The primary causes of choked flow are:

-

High Flow Rates: When the gas is flowing at very high velocities, it may approach the speed of sound, which results in choked flow.

-

Reduced Pressure Downstream: Choked flow occurs when the downstream pressure is low enough to allow the fluid velocity to reach sonic conditions.

-

Valve or Piping Restrictions: Inadequate valve size or narrow pipe diameters may restrict the flow of gas, creating conditions conducive to choked flow.

4.3 Effects of Choked Flow

The effects of choked flow are critical in many gas handling systems:

-

Flow Limitation: Once choked flow is reached, further increases in upstream pressure cannot increase flow, which limits the control over the system.

-

Energy Loss: Choked flow represents a loss of potential energy because the system cannot utilize additional pressure to increase flow.

-

System Instability: Choked flow can cause operational instability, especially in processes requiring precise flow regulation and control.

4.4 Preventing Choked Flow

To avoid choked flow:

-

Proper Valve Sizing: Ensure the valve is sized appropriately for the expected flow conditions. Oversized or undersized valves may lead to choked flow.

-

Use of Pressure Regulators: Installing a downstream pressure regulator can help prevent the system from reaching conditions conducive to choked flow.

-

High-Flow Valves: Some valves are designed specifically to handle high-flow rates without causing choking, thus preventing sonic velocities from being reached.

5. Conclusion

In the oil, gas, and process industries, understanding the causes, effects, and solutions for control valve cavitation, flashing, and choked flow is crucial for maintaining system reliability and performance. These phenomena not only impact valve performance but can also lead to significant damage, energy losses, and operational instability. By implementing proper valve sizing, utilizing anti-cavitation technologies, ensuring stable downstream pressures, and monitoring system conditions, these issues can be mitigated, leading to more efficient and reliable process operations.

Proper training, regular maintenance, and detailed system design are essential in preventing cavitation, flashing, and choked flow, ensuring the long-term health and performance of control valve systems in critical process environments.