The Ultimate Guide to Orifice Plates

An interactive exploration of concentric, eccentric, and segmental orifice plates for industrial flow measurement.

How Does an Orifice Plate Work?

An orifice plate is a simple device used to measure the flow rate of a fluid in a pipe. It's a thin plate with a hole. When fluid passes through this restriction, its pressure drops. By measuring this pressure difference (ΔP) before and after the plate, we can calculate the flow rate (Q).

Key Principle: The pressure drop is proportional to the square of the flow rate.

Q ∝ √ΔP

Explore the Types of Orifice Plates

Which Orifice Plate Do You Need?

Select your process conditions to get a recommendation.

1. Fluid Type

2. Fluid Phase

3. Primary Concern

Concentric

Best for clean, single-phase fluids where accuracy is key.

Eccentric

Ideal for fluids with some solids or entrained gases to prevent buildup.

Segmental

The choice for heavy slurries and fluids with high solid content.

At-a-Glance Comparison

| Feature | Concentric | Eccentric | Segmental |

|---|---|---|---|

| Bore Position | Centered | Offset (Tangent to pipe) | Bottom Segment |

| Suitable Fluids | Clean fluids (gas, liquid) | Fluids with some solids/gas | High solid content, slurries |

| Accuracy | High | Medium | Low to Medium |

| Clogging Risk | Medium | Low | Very Low |

| Common Uses | Steam, natural gas, water | Crude oil, wastewater | Pulp, mining slurries |

Introduction

Flow measurement plays a pivotal role in process industries, especially in sectors like oil and gas, petrochemicals, power generation, water treatment, and pharmaceuticals. Among the various types of flow meters available, orifice plate flow meters stand out due to their simplicity, reliability, and cost-effectiveness. The orifice plate, which is a primary flow element used in differential pressure (DP) type flow meters, comes in multiple configurations to suit different process conditions.

This blog explores the three main types of orifice plates—Concentric, Eccentric, and Segmental—covering their construction, working principle, typical applications, advantages, and selection criteria.

Basic Working Principle of an Orifice Plate

An orifice plate is a thin metal plate with a precision-machined hole (or orifice) in it. When fluid passes through this restriction, it experiences a pressure drop. The pressure is measured before and after the orifice using a DP transmitter. This pressure differential is then used to calculate flow using Bernoulli’s equation.

Key Principle:

The pressure drop (ΔP) across the orifice is proportional to the square of the flow rate.

Q∝ΔP

Orifice plates are standardized according to ISO 5167, ASME, and API standards.

Types of Orifice Plates

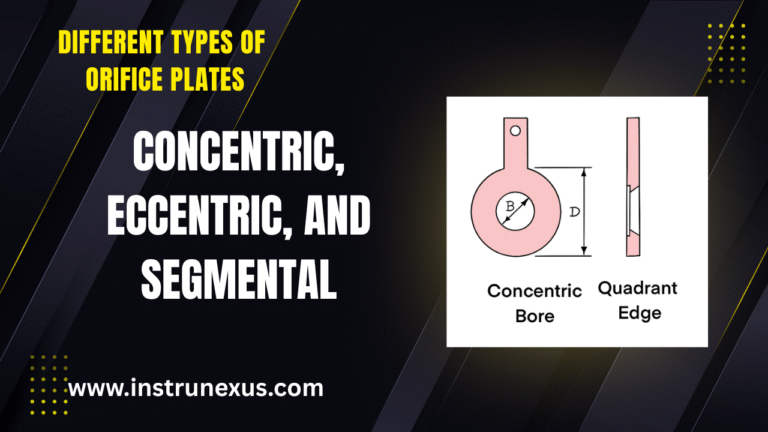

1. Concentric Orifice Plate

Construction:

-

The bore is perfectly circular and located at the center of the plate.

-

The plate itself is usually made of stainless steel, monel, or carbon steel.

-

Thickness varies from 3 mm to 12 mm depending on line size and pressure.

Working:

As the fluid passes through the central hole, a vena contracta is formed downstream where pressure is at its lowest. The pressure drop is measured between the upstream and downstream taps.

Applications:

-

Clean gases and liquids

-

Steam service

-

Water distribution systems

-

Natural gas pipelines

Advantages:

-

Widely standardized (e.g., ISO 5167)

-

Accurate for clean and single-phase fluids

-

Low cost and easy to install

Limitations:

-

Not suitable for dirty or slurry fluids

-

Can clog or erode in particulate-laden flows

2. Eccentric Orifice Plate

Construction:

-

Similar to the concentric type but with the bore offset from the centerline.

-

The edge of the hole is tangent to the inside diameter of the pipe.

-

Available in beveled and square-edged types.

Working:

The eccentric orifice allows solids or entrained gases to pass through without getting trapped. The offset bore helps prevent buildup by aligning with the bottom (for liquids) or top (for gases) of the pipe.

Applications:

-

Fluids containing entrained solids

-

Slurries or viscous fluids

-

Wastewater and sewage

-

Crude oil with sediments

-

Natural gas with condensates

Advantages:

-

Prevents solid settling and clogging

-

Better suited for multiphase or dirty fluids

-

Can be installed in horizontal or vertical lines

Limitations:

-

Requires careful orientation during installation

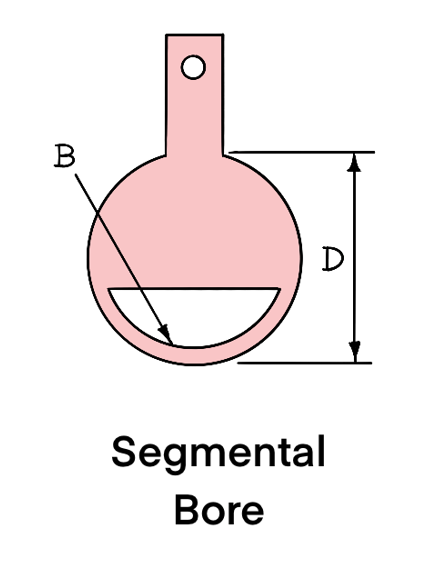

3. Segmental Orifice Plate

Construction:

-

The orifice is a segmental cut or a portion of a circle, often forming a semi-circular or partial arc at the bottom of the plate.

-

Designed to allow flow of large particles without restriction.

Working:

The segmental opening is designed to match the sediment or solid-carrying profile of the fluid. This allows solid particles to flow through easily, minimizing deposition.

Applications:

-

Slurries with high solid content

-

Pulp and paper industry

-

Mining operations

-

Ash or coal slurry in thermal power plants

-

Petrochemical wastewater

Advantages:

-

Handles heavily contaminated or high-viscosity fluids

-

Prevents plugging and erosion damage

-

Ideal for horizontal lines with solid transport

Limitations:

-

Lower accuracy due to irregular flow profile

-

Requires flow conditioning for better results

Comparison Table

| Feature | Concentric | Eccentric | Segmental |

|---|---|---|---|

| Bore Position | Centered | Offset to bottom/top | Bottom segment |

| Suitable Fluids | Clean fluids | Fluids with solids/gas | High solid content |

| Accuracy | High | Medium | Low to Medium |

| Installation Care | Standard | Must be oriented | Must be oriented |

| Clogging Risk | Medium | Low | Very Low |

| Common Uses | Steam, clean water | Crude oil, wastewater | Slurries, pulp |

Orifice Plate Construction Standards

Orifice plates are manufactured according to:

-

ISO 5167 – International Standard for flow measurement by differential pressure devices

-

ASME MFC-3M – Measurement of fluid flow using orifice, nozzle, and venturi

-

API RP 550 / API MPMS – Recommended practices for flow measurement in oil & gas

Common materials include:

-

Stainless steel (SS316/SS304)

-

Monel, Inconel, Hastelloy

-

PTFE-coated plates for corrosive services

Installation Guidelines

-

Tapping Location: Pressure taps can be flange taps, corner taps, D-D/2 taps (upstream and downstream located at 1D and 0.5D), or vena contracta taps.

-

Straight Length Requirement: Orifice plates require straight run lengths upstream and downstream to ensure laminar flow.

-

Typically 10D upstream and 5D downstream for concentric orifices.

-

-

Orientation:

-

Eccentric: Bore at bottom for liquids, top for gases

-

Segmental: Segment cut bottom for liquid-solid, top for gas-solid

-

Selection Criteria

When selecting an orifice plate type, consider the following:

-

Fluid Type:

-

Clean → Concentric

-

Dirty/Slurry → Eccentric/Segmental

-

-

Phase:

-

Single-phase → Concentric

-

Two-phase (gas-liquid or solid-liquid) → Eccentric/Segmental

-

-

Pipe Size and Velocity:

-

Higher velocity = Greater wear risk = Prefer beveled edge

-

-

Installation Location:

-

Horizontal or vertical line

-

Direction of flow and presence of bends or valves

-

-

Maintenance Access:

-

If frequent cleaning is required, eccentric or segmental types are preferred.

-

Advantages of Orifice Plates in General

-

Cost-Effective: One of the cheapest primary flow elements

-

No Moving Parts: Minimal wear and tear

-

Wide Range: Can be used for liquids, gases, and steam

-

Proven Technology: Long-established in industry standards

Conclusion

Choosing the right type of orifice plate—concentric, eccentric, or segmental—depends heavily on the process medium, installation conditions, and required accuracy. While concentric plates are suitable for most clean services, eccentric and segmental plates offer superior performance in dirty, viscous, or slurry-laden environments.

Understanding these differences not only ensures accurate flow measurement but also minimizes downtime, maintenance costs, and process inefficiencies. For critical applications in oil & gas and process industries, always ensure your orifice plate design complies with international standards like ISO 5167 and is installed following proper engineering practices.