A Deep Dive into Displacer Technology

Explore the foundational principles, mechanical designs, industrial applications, and lifecycle management of one of process control's most reliable level measurement technologies. This interactive guide translates complex engineering concepts into an easy-to-understand format.

The Principle of Buoyancy

The entire technology is built on Archimedes' Principle. As the liquid level rises, it submerges more of a weighted cylinder (the displacer), increasing the upward buoyant force. The instrument measures the resulting change in the displacer's 'apparent weight' to determine the liquid level. However, this measurement is critically dependent on a stable fluid density. Interact with the diagram below to see this principle in action.

Buoyant Force

Increases as level rises.

Apparent Weight

Decreases as level rises.

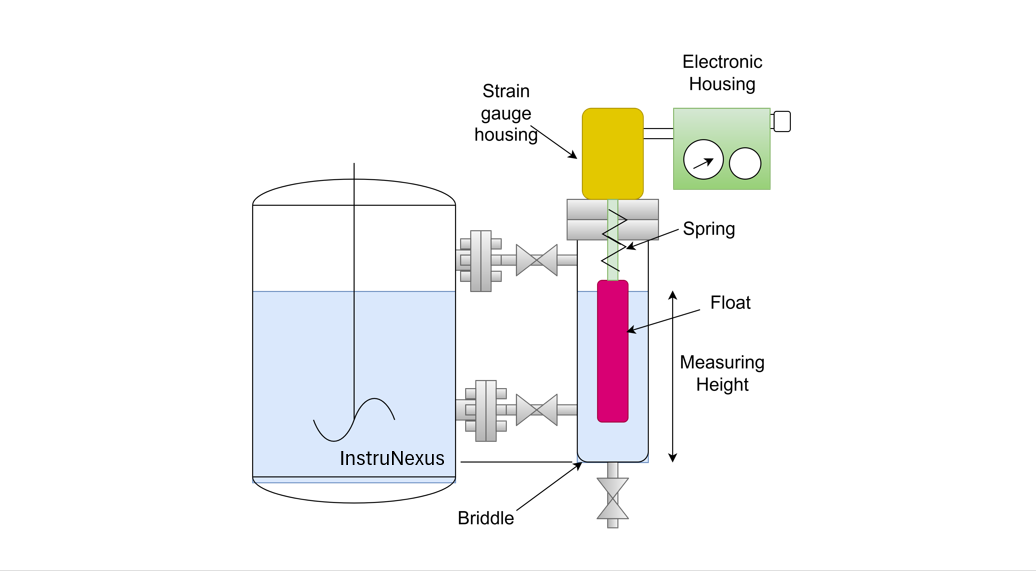

Anatomy of a Displacer Transmitter

A displacer transmitter is an electromechanical device that converts a change in level into a standard electrical signal. It consists of three main parts: the displacer element in contact with the fluid, a mechanism to transmit force, and the transmitter head containing the electronics. This section explores these components and compares the two primary mechanical designs.

A Tale of Two Designs

Traditional Torque Tube

Modern Spring-Operated (LVDT)

Industrial Use Cases

Displacers are not general-purpose tools; they are specialists chosen for their ability to perform reliably in the most challenging industrial environments. Their primary applications involve high temperatures, high pressures, aggressive fluids, and the critical task of measuring the interface between two different liquids.

Oil & Gas / Refining

A core application is measuring the oil-water interface in three-phase separators. Precise control is vital to prevent product loss and contamination. Displacers excel in these high-pressure, high-temperature environments.

Chemical & Petrochemical

Used in reactors with corrosive liquids. When placed in an external cage, they are immune to turbulence from agitators and surface foam, providing a true, stable level reading where non-contact methods fail.

Power Generation

A critical safety application is monitoring water level in boiler steam drums. The extreme pressure and temperature inside a boiler demand the rugged, mechanical reliability that only displacers can provide.

Implementation & Lifecycle

Successful application depends on proper installation, calibration, and maintenance. Due to its mechanical nature, attention to these lifecycle stages is critical for ensuring accurate and reliable performance over the long term.

Installation Strategies

External Cage Mounting: The most common method. The displacer is housed in a chamber mounted to the side of the vessel. This allows the instrument to be isolated, drained, and serviced without shutting down the main process, a major operational benefit.

Internal Mounting: The displacer is suspended directly inside the vessel. This is a simpler installation but requires a full process shutdown for any maintenance on the displacer element itself.

Calibration Procedures

Dry (Bench) Calibration: Performed in a workshop using weights to simulate the displacer's apparent weight at 0% and 100% levels. This is a convenient method that avoids handling process fluids.

Wet (Field) Calibration: The most accurate method. It involves physically adjusting the liquid level in the vessel to the 0% and 100% points and setting the transmitter's output accordingly. This uses the actual process fluid under real conditions.

Technology Showdown

How do displacers stack up against other level measurement technologies? While displacers are robust, they are sensitive to fluid density changes. Modern technologies like Guided Wave Radar (GWR) are often preferred for their immunity to process variations. Use the interactive chart below to compare their performance across key criteria.

Conclusion & Future Outlook

While a mature technology, the displacer transmitter remains a highly relevant tool for specific industrial challenges. Its evolution has enhanced reliability, and its core strength lies in exceptional performance under harsh conditions—high temperatures, pressures, and critical interface measurements. However, its dependence on stable fluid density is a significant limitation.

The Rise of Guided Wave Radar (GWR)

The trend is toward smarter, lower-maintenance solutions. GWR technology, with its immunity to density changes and solid-state design, is increasingly replacing displacers. Despite this, displacers will continue to hold a vital role in niche applications at the extreme edges of process conditions where their long history of reliability provides unmatched operational confidence.

Introduction

The Displacer Type Level Transmitter is a widely used level measurement device in the oil & gas, chemical, and power generation industries. It operates based on the principle of Archimedes’ Law, which states that a body submerged in a fluid experiences a buoyant force equal to the weight of the fluid it displaces. The transmitter senses this force change through a mechanical or electronic system and converts it into a level signal.

This type of level transmitter is especially suitable for applications involving high temperatures, high pressures, or corrosive fluids and is used to measure the level of liquids in tanks, vessels, or columns.

Basic Construction

A typical Displacer Type Level Transmitter consists of the following main components:

-

Displacer Element: A cylindrical or rod-shaped solid body made of stainless steel or other suitable material, suspended in the tank where level measurement is required.

-

Torque Tube Assembly: Connects the displacer to a pivot arm and allows rotational movement in response to buoyant forces.

-

Range Spring and Magnetic Coupling: Balances the force and transmits the motion to the sensing element.

-

Transmitter Housing: Contains the sensor mechanism and electronics that convert mechanical motion into an electrical output (e.g., 4–20 mA).

-

Flange or Cage Mounting: The transmitter may be mounted directly into the vessel or externally through a side-mounted cage.

Working Principle

1. Buoyant Force and Archimedes’ Principle

When the displacer is suspended in the process fluid, it displaces a volume of liquid. According to Archimedes’ Principle:

Buoyant Force (Fb) = Weight of Displaced Liquid

As the liquid level in the tank rises or falls, the volume of liquid displaced by the displacer changes. This changes the net force acting on the displacer, which leads to a mechanical movement.

2. Force Balance and Torque Tube Movement

-

At lower liquid levels, only a small portion of the displacer is submerged, and the buoyant force is less.

-

As the level rises, more of the displacer gets submerged, increasing the buoyant force acting upward.

-

This causes a torque in the torque tube assembly, which is proportional to the change in buoyant force.

The torque tube twists accordingly, and this rotation is directly proportional to the liquid level in the vessel.

3. Signal Transmission

-

The mechanical displacement is either directly transmitted to a pointer (in local indicators) or converted into an electrical signal using electronic sensors and transmitters.

-

Modern displacer level transmitters use Hall-effect sensors or LVDTs (Linear Variable Differential Transformers) to convert the mechanical motion into a 4–20 mA output.

-

The transmitter can also be connected to a DCS or PLC for continuous monitoring and control.

Mathematical Representation

Let:

-

Vd = Volume of displacer submerged

-

ρ = Density of liquid

-

g = Gravitational acceleration

Then,

Buoyant Force:

Fb=ρ⋅g⋅Vd

As the fluid level increases, Vd increases, and so does Fb. This change is what the transmitter senses and translates into a proportional signal.

Application Considerations

Advantages:

-

Suitable for high pressure and high temperature.

-

Can be used in dirty or viscous liquids.

-

Immune to foam and vapor layers.

Limitations:

-

Mechanical parts are prone to wear over time.

-

Calibration required when fluid density changes.

-

Not ideal for rapid level changes or slurry applications.

Installation Types

-

Cage Mounted: For external measurement with isolation valves—ideal for maintenance and safety.

-

In-Tank Mounted: Displacer suspended directly inside the tank—used where cage mounting is not feasible.

Use Cases in Industry

-

Oil & Gas: Level measurement in separators, knock-out drums, or reflux drums.

-

Petrochemical: Interface level detection in multi-phase separators.

-

Power Plants: Condensate and feedwater tank level control.

-

Chemical Plants: Measurement in reactors or solvent tanks.

Displacer vs Other Level Technologies

| Feature | Displacer Type | Radar/Ultrasonic | DP Transmitter |

|---|---|---|---|

| Principle | Buoyancy (Archimedes’) | Time-of-flight/Reflection | Pressure differential |

| Contact/Non-contact | Contact | Non-contact | Contact (via impulse lines) |

| Temperature/Pressure Suitability | High | Moderate to High | High |

| Maintenance | Mechanical parts wear | Low | Impulse line clogging |

| Cost | Medium | High | Low to Medium |

Conclusion

Displacer Type Level Transmitters are reliable and time-tested instruments that provide accurate level measurements, especially under challenging process conditions. While newer technologies like radar and ultrasonic are gaining popularity, displacer transmitters still hold a vital place in process industries due to their ruggedness and versatility. Proper installation and calibration ensure accurate, repeatable performance in a wide range of applications.