Understanding Midstream and Downstream Operations in Oil and Gas: A Comprehensive Guide

The oil and gas industry is a colossal and intricate global network that powers our economies and fuels our daily lives. From the initial discovery of raw hydrocarbons deep within the earth to the gasoline in our cars and the plastics in our homes, the journey of oil and gas is a complex one. This journey is traditionally divided into three main sectors: upstream, midstream, and downstream. While upstream activities, focused on exploration and production, often take the spotlight, the midstream and downstream sectors are the vital arteries and refineries of this global energy system.

This comprehensive guide will delve deep into the worlds of midstream and downstream operations, demystifying their processes, exploring their technological advancements, and examining their critical roles in the energy value chain. Whether you’re an industry professional, an aspiring student, or simply a curious consumer, this article will provide you with a thorough understanding of how raw petroleum is transformed into the indispensable products we rely on every day.

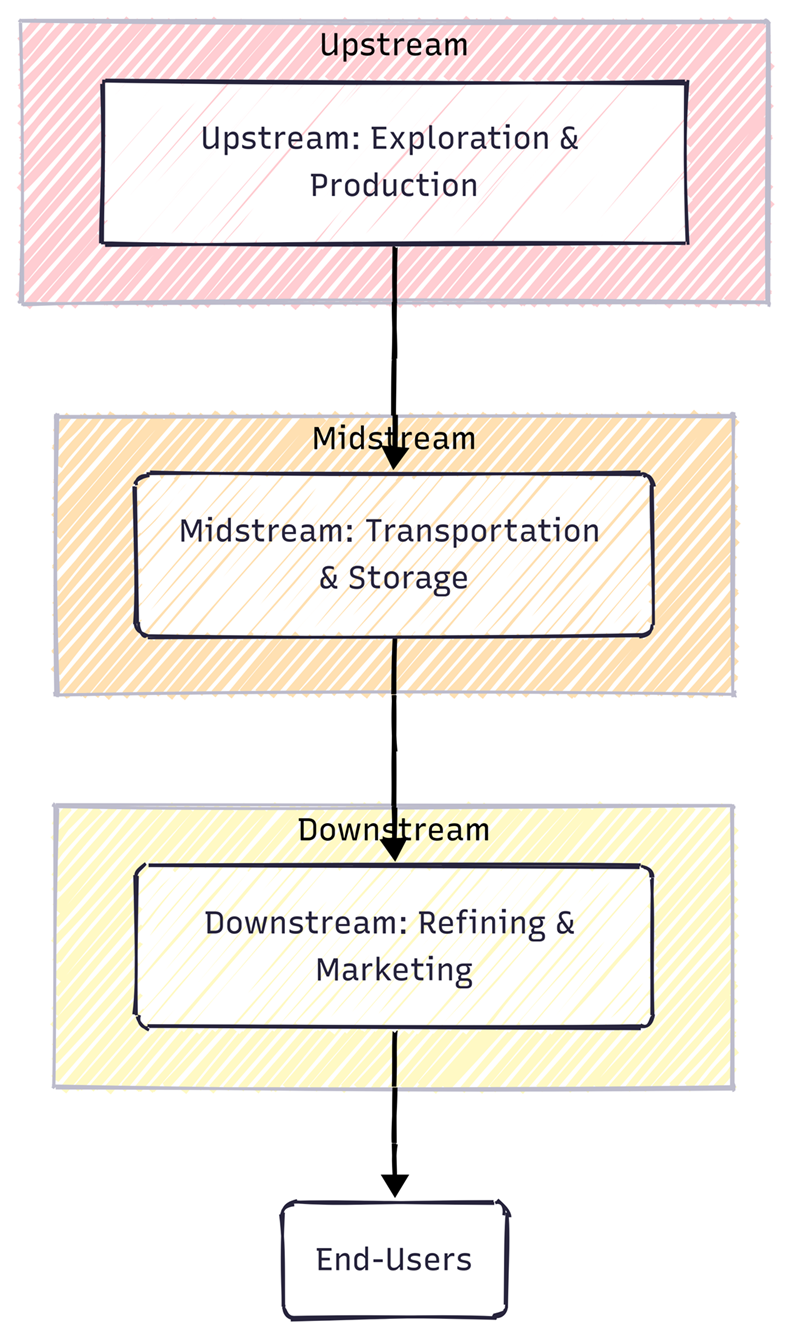

The Oil and Gas Value Chain: A Macro Overview

Before we immerse ourselves in the specifics of midstream and downstream, it’s essential to visualize the entire oil and gas value chain. Each sector represents a distinct yet interconnected stage in the journey of hydrocarbons.

Upstream, often referred to as the exploration and production (E&P) sector, is where the process begins. This involves geological surveys, drilling exploratory wells, and ultimately, the extraction of crude oil and natural gas from the ground. Once these raw materials are brought to the surface, the midstream sector takes over.

Midstream Operations: The Great Connector

The midstream sector acts as the crucial link between the upstream’s production sites and the downstream’s processing facilities. It is the logistical heart of the oil and gas industry, responsible for the safe, efficient, and reliable transportation and storage of raw hydrocarbons. Think of it as the intricate network of highways and warehouses for unrefined energy.

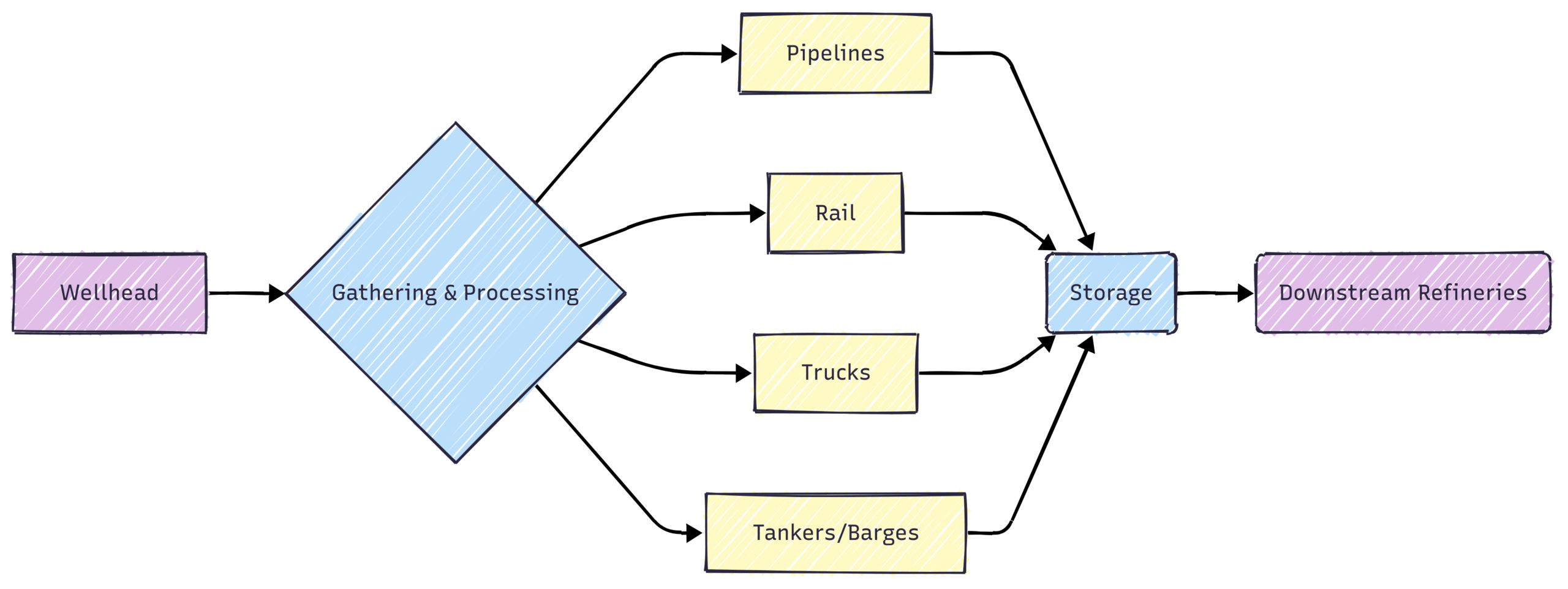

The primary functions of the midstream sector can be broken down into several key areas:

1. Gathering and Processing

Immediately after extraction, crude oil and natural gas are often mixed with water, sand, and other impurities. The initial phase of midstream operations involves “gathering” these raw streams from various wellheads and transporting them to processing facilities.

At these facilities, preliminary processing occurs to separate the oil, gas, and water. For natural gas, this stage is particularly crucial as it involves the removal of impurities like sulfur, carbon dioxide, and water to produce “pipeline-quality” natural gas. This processed gas is then ready for long-haul transportation.

2. Transportation: A Multi-Modal Approach

Transporting vast quantities of oil and gas over long distances is a monumental task. The midstream sector employs a variety of methods, each with its own advantages and applications:

Pipelines: The backbone of midstream transportation, pipelines are the most efficient and cost-effective way to move large volumes of crude oil, natural gas, and refined products over land. This extensive network of steel pipes can span thousands of miles, crossing diverse terrains and international borders.

Tankers and Barges: For transoceanic and inter-coastal transportation, massive tankers and smaller barges are indispensable. These vessels can carry enormous quantities of crude oil and liquefied natural gas (LNG) between continents, connecting global markets.

Rail: Rail transport offers a flexible alternative to pipelines, especially for accessing remote areas or for transporting smaller volumes of hydrocarbons. It is also a key mode of transport for products like propane and butane.

Trucks: Trucks are the go-to solution for short-haul transportation and for delivering products to end-users in regions not serviced by pipelines or rail. They offer unparalleled flexibility and are essential for the final leg of the distribution journey.

3. Storage: Ensuring a Stable Supply

Storage is another critical function of the midstream sector. Large storage facilities, such as tank farms for crude oil and underground salt caverns for natural gas, act as buffers in the supply chain. This storage capacity allows for a continuous and reliable supply of energy, even during periods of fluctuating production or demand. It also plays a vital role in energy security, providing a strategic reserve in case of supply disruptions.

Downstream Operations: From Raw to Refined

The downstream sector is where the magic of transformation happens. It takes the raw crude oil and natural gas delivered by the midstream sector and refines them into a vast array of finished products that power our world. This is the most consumer-facing segment of the industry, and its operations are complex and technologically intensive.

The core of downstream operations is the refinery, a sprawling industrial complex where crude oil is broken down and reconfigured into valuable products.

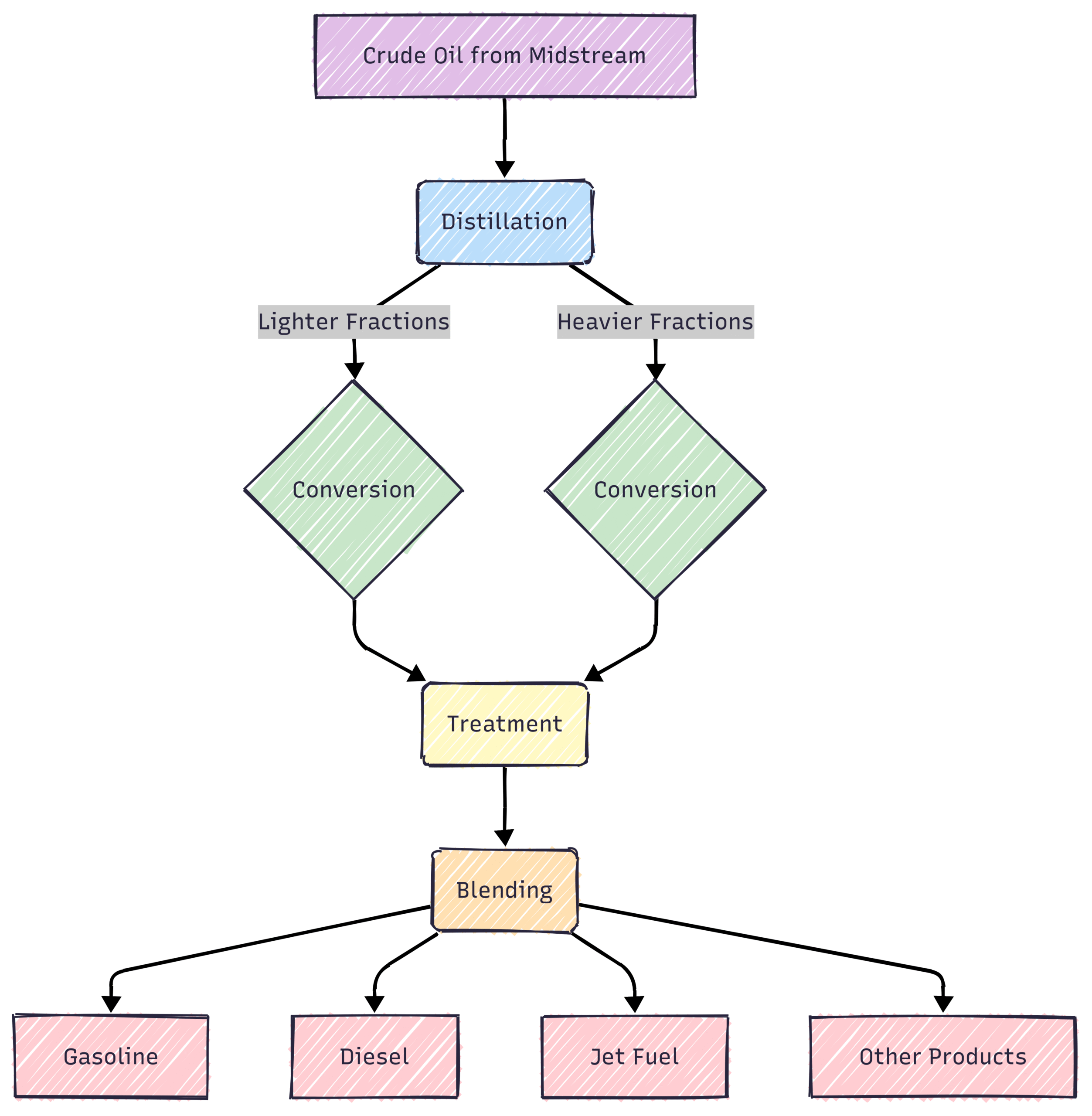

The Refining Process: A Symphony of Chemistry and Engineering

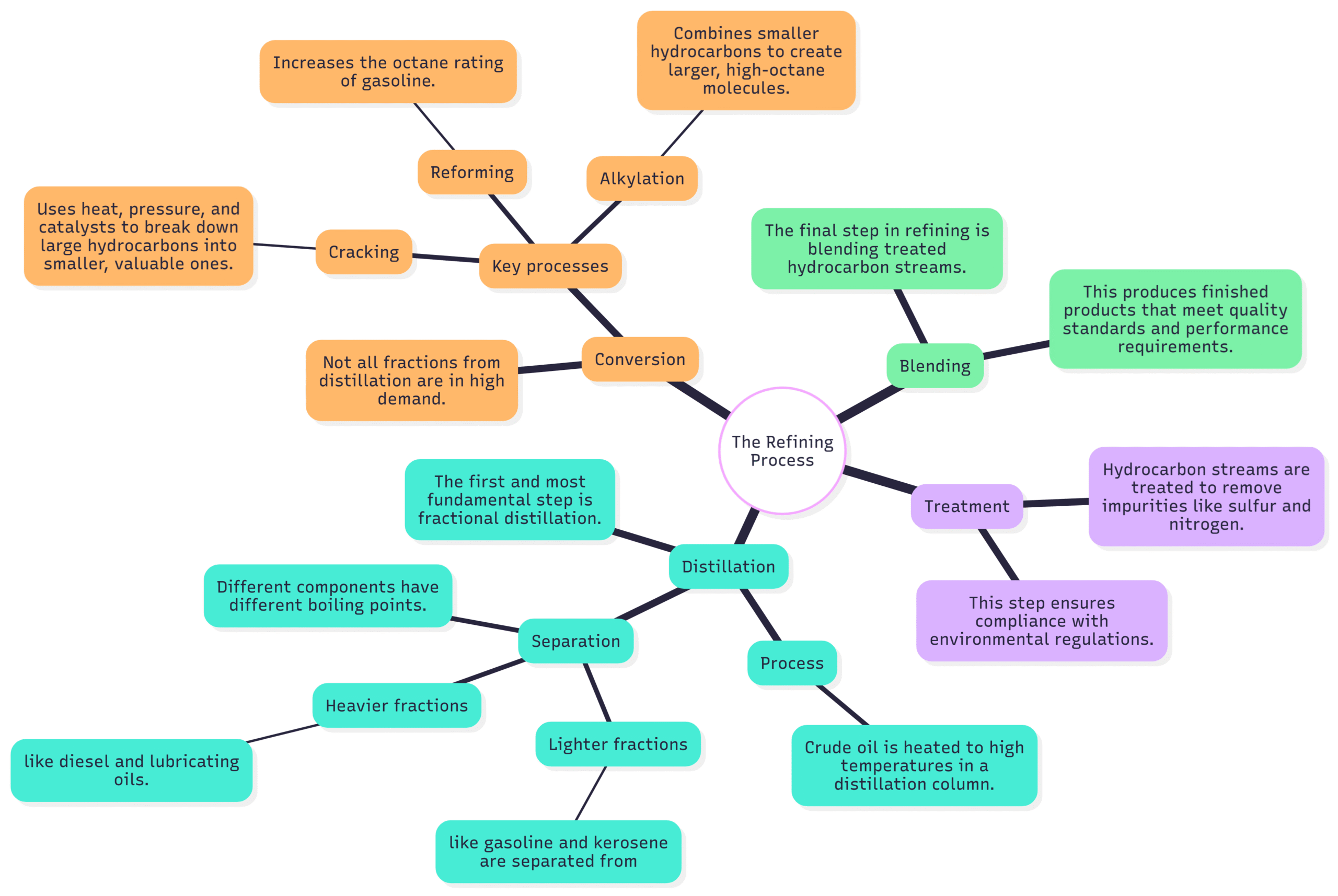

The refining process is a multi-stage endeavor that uses heat, pressure, and catalysts to separate and convert hydrocarbons. While the specific configuration of each refinery varies, the fundamental processes remain consistent.

Distillation (Separation): The first and most fundamental step is fractional distillation. Crude oil is heated to high temperatures in a distillation column. The different components, or “fractions,” of the crude oil have different boiling points and will vaporize at different temperatures. As the vapors rise through the column, they cool and condense at different levels, allowing for the separation of lighter fractions (like gasoline and kerosene) from heavier fractions (like diesel and lubricating oils).

Conversion: Not all fractions from distillation are in high demand. To maximize the output of valuable products, refineries use various conversion processes to break down or rearrange the molecular structure of the hydrocarbons. Key conversion processes include:

Cracking: This process uses heat, pressure, and catalysts to break down large, heavy hydrocarbon molecules into smaller, more valuable ones, such as gasoline.

Reforming: This process is used to increase the octane rating of gasoline by rearranging the molecular structure of the hydrocarbons.

Alkylation: This process combines smaller hydrocarbon molecules to create larger ones that are high in octane, a key component of high-performance gasoline.

Treatment: After separation and conversion, the various hydrocarbon streams are treated to remove impurities like sulfur, nitrogen, and heavy metals. This is a critical step to meet environmental regulations and to ensure the quality and performance of the final products.

Blending: The final step in the refining process is blending. The various treated hydrocarbon streams are carefully blended together to create finished products that meet specific quality standards and performance requirements. This is where different grades of gasoline, diesel, and other fuels are formulated.

Beyond the Refinery: Marketing and Distribution

Once the refining process is complete, the downstream sector is responsible for the marketing and distribution of these finished products to consumers and businesses. This involves a complex logistics network that includes pipelines, tankers, rail, and trucks to transport products to terminals, bulk storage facilities, and ultimately, to retail outlets like gas stations.

The downstream sector also encompasses the petrochemical industry, which uses byproducts from the refining process as feedstock to produce a vast array of chemicals, plastics, synthetic rubbers, and other materials that are fundamental to modern life.

Midstream vs. Downstream: A Tale of Two Sectors

While both midstream and downstream are integral to the oil and gas value chain, they have distinct characteristics, business models, and career opportunities.

Feature | Midstream | Downstream |

Primary Focus | Transportation and storage of raw hydrocarbons | Refining of crude oil and marketing of finished products |

Key Assets | Pipelines, storage tanks, LNG terminals, rail cars, trucks | Refineries, petrochemical plants, distribution terminals, retail stations |

Business Model | Primarily fee-based; revenue generated from tariffs for transportation and storage | Margin-based; profit is the spread between the cost of crude oil and the price of refined products |

Risk Profile | Generally lower risk, with more stable cash flows due to long-term contracts | Higher risk, as profits are exposed to volatile commodity prices and refining margins |

Career Paths | Pipeline engineers, logistics and operations managers, terminal operators, commercial analysts | Chemical engineers, process engineers, refinery operators, marketing and trading professionals |

The Future of Midstream and Downstream: Navigating the Energy Transition

The global energy landscape is undergoing a profound transformation, driven by concerns about climate change, the rise of renewable energy sources, and evolving consumer demands. Both the midstream and downstream sectors are at the forefront of this transition, facing both challenges and opportunities.

Key Trends Shaping the Future:

Decarbonization and Sustainability: There is increasing pressure on the oil and gas industry to reduce its carbon footprint. Both sectors are investing in technologies to improve energy efficiency, reduce methane emissions, and explore carbon capture, utilization, and storage (CCUS) solutions. Downstream is also seeing a growing demand for lower-carbon fuels, such as biofuels and hydrogen.

Digitalization and Automation: The adoption of digital technologies like artificial intelligence (AI), machine learning, and the Internet of Things (IoT) is revolutionizing operations in both sectors. Predictive analytics is being used to optimize pipeline integrity and prevent leaks in the midstream, while AI is helping to optimize refinery operations and improve safety in the downstream.

Shifting Demand Patterns: The rise of electric vehicles (EVs) is expected to impact long-term demand for gasoline. However, demand for other refined products, such as petrochemicals and jet fuel, is projected to remain strong. This is driving a shift in refinery configurations to produce more chemicals and fewer transportation fuels.

Infrastructure Adaptation: The midstream sector is exploring ways to adapt its vast infrastructure to transport new energy sources like hydrogen and captured carbon dioxide. This will be crucial for enabling a low-carbon energy system.

Conclusion: The Enduring Importance of Midstream and Downstream

The midstream and downstream sectors of the oil and gas industry are often the unsung heroes of our modern energy system. They are the intricate and powerful engines that transform raw hydrocarbons into the fuels and products that have shaped our world. While the energy transition presents significant challenges, the ingenuity and adaptability that have defined these sectors for over a century will be crucial in navigating the path to a more sustainable energy future. Understanding their complex operations is key to appreciating the immense scale and importance of the global energy landscape.