MMSCFD, or Million Standard Cubic Feet per Day, is a unit of measurement used to quantify the flow rate of natural gas. It’s widely used in the oil and gas industry because it provides a standardized, reliable, and universally understood metric for measuring large volumes of gas. The “standard” part of the term is crucial, as it corrects the gas volume to a fixed set of pressure and temperature conditions, ensuring that measurements are accurate and comparable regardless of where or how they are taken. This standardization is essential for production monitoring, processing operations, transportation logistics, and, most importantly, for the commercial buying and selling of natural gas (custody transfer).

What is MMSCFD and Why It’s the Gold Standard in Gas Measurement

In the vast and complex world of energy, precision is everything. From the deep underground reservoirs to the pipelines that crisscross continents, every molecule of natural gas must be accounted for. This brings us to a fundamental question: how do we measure something we can’t see, especially in the colossal quantities required to power our world? The answer lies in a single, ubiquitous acronym: MMSCFD.

If you’ve ever been near the oil and gas industry, you’ve likely heard this term. It’s cited in production reports, financial statements, and engineering plans. But what does it actually mean? Why has this specific unit become the bedrock of natural gas measurement? This guide will demystify MMSCFD, exploring its components, the science behind its necessity, and its indispensable role across the entire natural gas value chain. Whether you’re an industry veteran, a curious investor, or simply someone interested in the mechanics of our energy system, understanding MMSCFD is key to understanding the business of natural gas.

Decoding MMSCFD: Breaking Down the Acronym

At first glance, “MMSCFD” can seem like cryptic industry jargon. However, breaking it down into its individual components reveals a clear and logical system of measurement.

M & MM: Let’s start with the “M”s. In many industries, “M” is an abbreviation for a thousand, derived from the Roman numeral ‘M’. In the oil and gas sector, this convention is taken a step further.

M = 1,000 (Thousand)

MM = 1,000 x 1,000 = 1,000,000 (Million) So, the “MM” in MMSCFD stands for Million. This immediately tells us we are dealing with very large quantities, which is typical for commercial gas wells, pipelines, and processing facilities.

SCF – Standard Cubic Foot: This is the most critical part of the acronym. A cubic foot is a simple measurement of volume—picture a box that is one foot long, one foot wide, and one foot high. However, gases are compressible fluids. Their volume can change dramatically with shifts in temperature and pressure. A cubic foot of gas at the high pressure of an underground reservoir is very different from a cubic foot of gas at the lower pressure in a pipeline. To create a fair and consistent standard for measurement, the industry agrees upon a set of “standard conditions.”

Standard Pressure is typically defined as 14.7 pounds per square inch absolute (psia), which is the average atmospheric pressure at sea level.

Standard Temperature is typically defined as 60°F (15.6°C). A Standard Cubic Foot (SCF) is the amount of gas that would occupy a volume of one cubic foot if it were brought to these standard conditions. By correcting every measurement back to this baseline, we can compare apples to apples, whether the gas is in Texas, Qatar, or Siberia.

D – Day: The final letter, “D,” simply stands for Day. This signifies that the measurement is not a static volume but a flow rate over a 24-hour period. It tells us how many million standard cubic feet of gas are being produced, transported, or sold each day.

Putting it all together, MMSCFD stands for Million Standard Cubic Feet per Day. It is the industry’s standard rate for quantifying the flow of natural gas.

Why Standard Conditions? The Science of Gas Behavior

To truly appreciate the importance of the “S” in MMSCFD, we need to look at the fundamental physics of gas. The behavior of gases is described by the Ideal Gas Law, a cornerstone of chemistry and physics.

The formula is expressed as:

Where:

P is the absolute pressure of the gas.

V is the volume of the gas.

n is the amount of substance of the gas (measured in moles).

R is the ideal, or universal, gas constant.

T is the absolute temperature of the gas.

The law shows a direct relationship between pressure, volume, and temperature. If you change one, at least one of the others must also change.

Effect of Pressure: If you increase the pressure on a fixed amount of gas (while keeping temperature constant), its volume decreases. The molecules are squeezed closer together.

Effect of Temperature: If you increase the temperature of a fixed amount of gas (while keeping pressure constant), its volume increases. The molecules move faster and push outward, occupying more space.

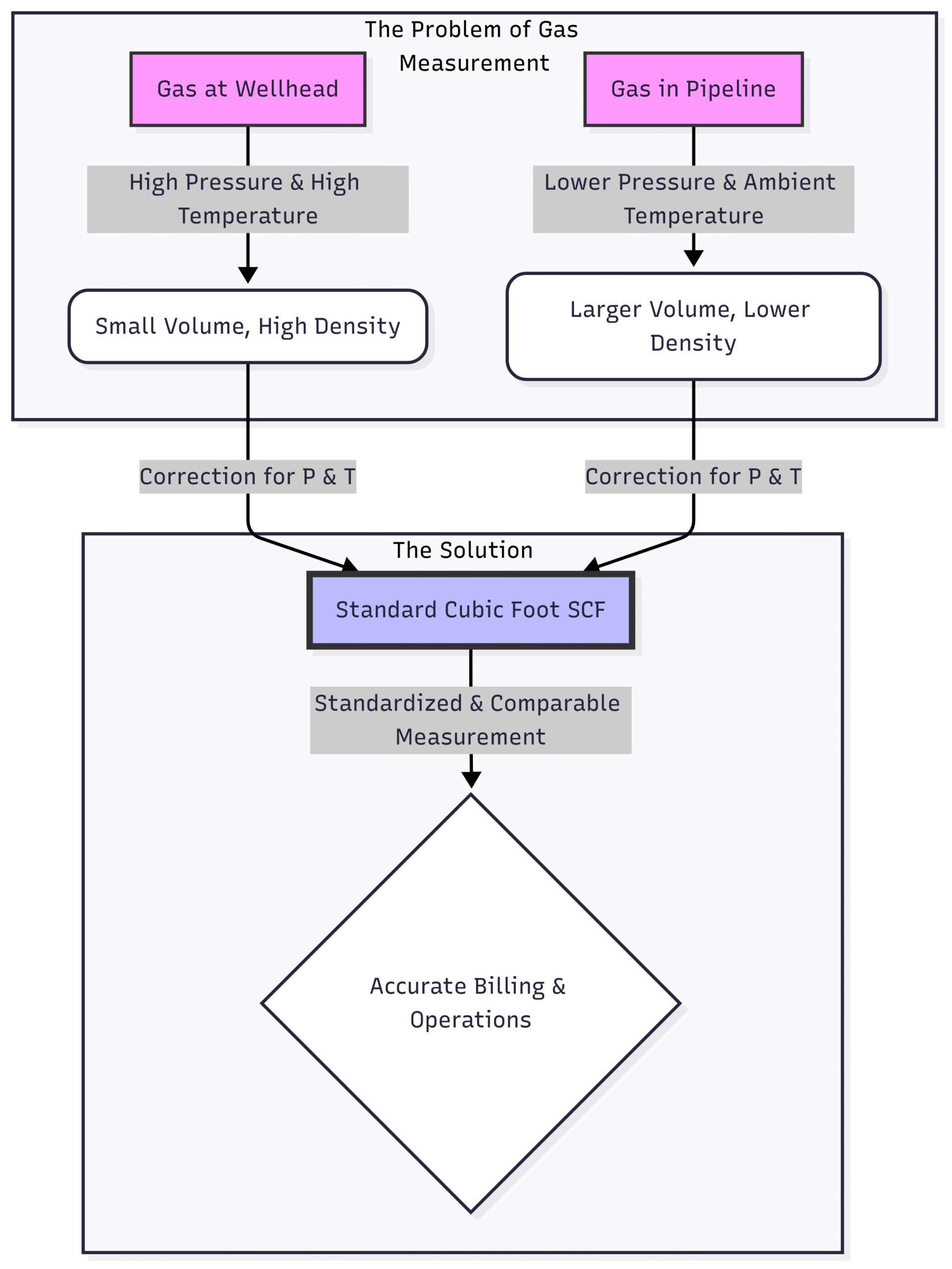

Imagine buying a “cubic foot” of gas directly from a wellhead. At that point, the gas is under immense pressure and is often very hot. That single cubic foot contains a massive number of gas molecules. Now, imagine buying a “cubic foot” of gas after it has been processed and is flowing through a low-pressure distribution line on a cold day. That cubic foot would contain far fewer gas molecules. Without standardization, the term “cubic foot” would be meaningless for commercial purposes.

Standardizing to 60°F and 14.7 psia creates a fixed, universally agreed-upon benchmark. It ensures that one MMSCFD represents the same amount of energy (i.e., the same number of gas molecules) regardless of the actual flowing conditions.

The Indispensable Role of MMSCFD in the Oil & Gas Industry

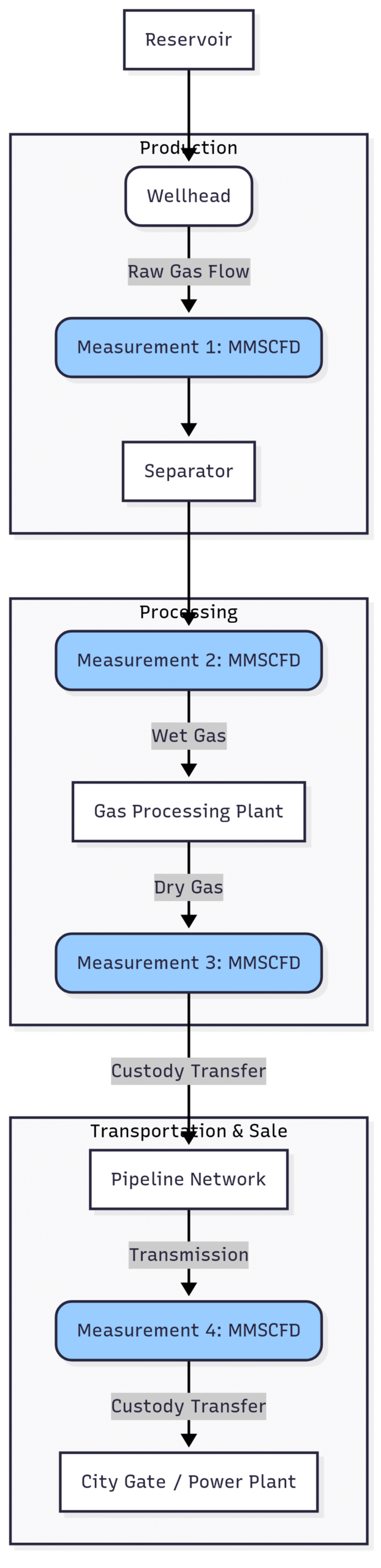

The use of MMSCFD permeates every stage of the natural gas journey, from extraction to consumption. It serves as the common language for engineers, geologists, operators, and accountants.

For Production and Reservoir Management

For a company operating a gas field, MMSCFD is the primary indicator of success. The flow rate of a well, measured in MMSCFD, is its vital sign.

Assessing Well Performance: A new well might initially produce at a high rate, say 50 MMSCFD. Geologists and engineers track this rate daily. A steady rate indicates a healthy, stable well. A rapidly declining rate could signal production issues or a smaller-than-expected reservoir.

Estimating Reserves: By analyzing the production decline curve (a graph of MMSCFD over time), engineers can forecast the total amount of gas a well is likely to produce over its lifetime. This is known as the Estimated Ultimate Recovery (EUR), a critical figure for a company’s valuation and investment planning.

Field Development Strategy: Monitoring the MMSCFD from multiple wells across a field helps operators understand the reservoir’s dynamics. This data informs crucial decisions, such as where to drill new wells, whether to implement artificial lift techniques, or when to invest in compression to maintain flow rates as reservoir pressure naturally declines.

For Processing and Transportation

Raw natural gas from the wellhead is not ready for your home stove. It’s a mixture of methane, other hydrocarbons (like ethane and propane), water vapor, and impurities (like carbon dioxide and hydrogen sulfide). This raw gas must be processed.

Plant Operations: A gas processing plant’s capacity is rated in MMSCFD. For example, a plant might be designed to handle 500 MMSCFD of inlet gas. Operators use MMSCFD measurements to ensure the plant is running efficiently, to track the volume of impurities being removed, and to measure the output of “pipeline-quality” dry gas.

Pipeline Logistics: Major pipelines are the arteries of the gas industry. Their capacity is also measured in MMSCFD or the larger BSCFD (Billion Standard Cubic Feet per Day). Pipeline operators use MMSCFD flow rates to manage nominations (requests for shipping space), ensure they don’t exceed the pipeline’s maximum pressure limits, and track the journey of gas from receipt points (from processors) to delivery points (to utilities).

For Metering and Custody Transfer

This is where MMSCFD becomes a unit of cash. Custody transfer is the point at which the ownership of the gas changes from one party to another. This could be from the producer to the pipeline company, from the pipeline to a power plant, or from a utility to an industrial customer.

Fair & Accurate Billing: All commercial transactions are based on the volume of gas transferred, measured and corrected to standard conditions. Invoices are based on the total volume in MSCF (Thousand Standard Cubic Feet) or MMBtu (Million British Thermal Units), which is directly calculated from the MMSCFD flow rate.

Dispute Prevention: Because both buyer and seller agree on the definition of a “Standard Cubic Foot,” the use of MMSCFD minimizes commercial disputes. The measurement is objective and verifiable, based on sophisticated metering equipment that continuously measures flow, pressure, and temperature and performs the correction calculation in real time.

The following diagram illustrates the journey of natural gas and the critical points where MMSCFD is measured.

MMSCFD in Practice: How It’s Measured

You can’t just stick a bucket under a pipe to measure gas flow. The industry relies on highly accurate, sophisticated meters to determine the flow rate, which is then converted to MMSCFD. The most common types include:

Orifice Meters: These are one of the oldest and most common types. They work by placing a precisely machined plate with a hole (an orifice) inside the pipe. This constriction creates a pressure drop across the plate. By measuring this pressure differential, along with the static pressure and temperature, engineers can calculate the flow rate using well-established fluid dynamics equations.

Turbine Meters: These meters contain a small rotor with blades, similar to a windmill. As gas flows through the pipe, it spins the rotor. The speed at which the rotor spins is directly proportional to the gas velocity and, therefore, the flow rate.

Ultrasonic Meters: These are modern, highly accurate meters that use sound waves. They send ultrasonic pulses diagonally across the pipe, both with and against the direction of the gas flow. The gas flow causes the pulse traveling downstream to arrive slightly faster than the pulse traveling upstream. The meter measures this tiny time difference to calculate the precise velocity of the gas and its volumetric flow rate.

Regardless of the meter type, the raw data (actual volume, pressure, temperature) is fed into a flow computer. This specialized device continuously performs the calculations required by the Ideal Gas Law to correct the measured volume to standard conditions, providing a real-time readout in MMSCFD.

Putting MMSCFD in Perspective: Conversions and Scale

While MMSCFD is the standard in many parts of the world, especially North America, it’s useful to know how it relates to other common units of energy and volume.

Common Conversions

To Metric Units: The most common international unit for gas volume is the cubic meter (m3).

1 Standard Cubic Foot (SCF) ≈ 0.0283 Cubic Meters (m3)

Therefore, 1 MMSCFD ≈ 28,300 m3/day

To Energy Equivalence (BOE): In finance and high-level reporting, companies often want to state their total hydrocarbon production in a single unit. This is done by converting gas to Barrels of Oil Equivalent (BOE). The conversion is based on energy content. A barrel of oil has roughly the same amount of energy as 6,000 standard cubic feet of natural gas.

1 BOE ≈ 6 MSCF (6,000 SCF)

Therefore, 1 MMSCFD ≈ 166.7 BOE/Day

To Energy Content (BTU): Ultimately, gas is sold for its ability to produce heat. This is measured in British Thermal Units (BTU). While the BTU content of natural gas can vary slightly depending on its composition, a common approximation is:

1 SCF ≈ 1,030 BTU

Therefore, 1 MMSCFD ≈ 1.03 Billion BTU/day (or 1,030 MMBtu/day). This is often rounded to 1 Billion BTU/day for simplicity.

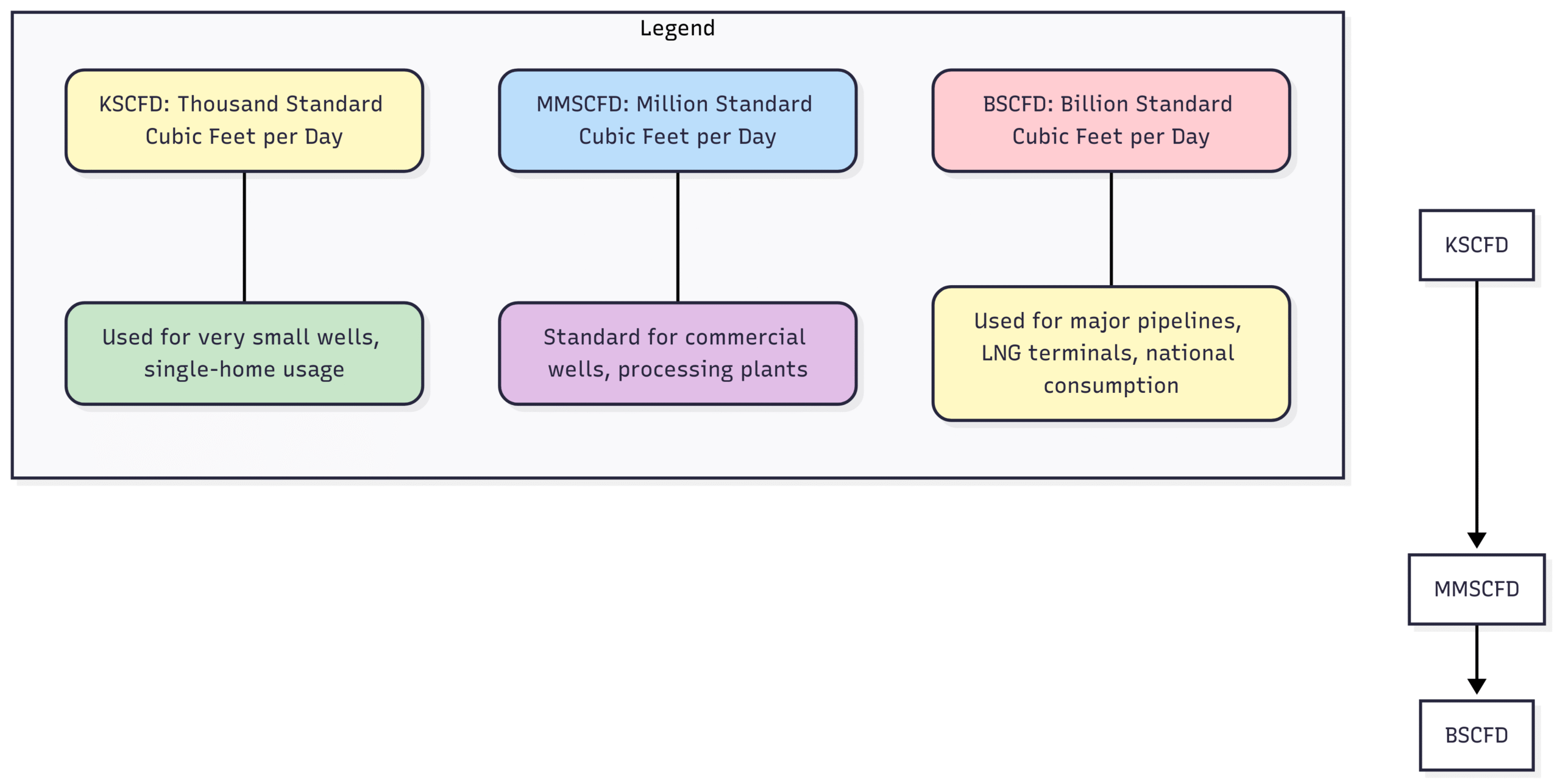

Understanding the Scale

The prefixes used in gas measurement help to contextualize the scale of operations.

A single home might use around 200 SCF per day on a cold day.

A single productive gas well might produce anywhere from 1 to 50 MMSCFD.

A large gas processing plant might handle 500 MMSCFD.

A major interstate pipeline could transport 2 BSCFD (or 2,000 MMSCFD).

A world-scale Liquefied Natural Gas (LNG) plant train can produce over 1,000 MMSCFD.

The Final Word

MMSCFD is far more than a random collection of letters. It is a precisely defined unit that provides a stable, reliable, and universal foundation for the global natural gas industry. By creating a standard for volume corrected to specific conditions of pressure and temperature, MMSCFD ensures fairness in commerce, accuracy in engineering, and clarity in financial reporting. It allows a well operator in Qatar to speak the same quantitative language as a pipeline engineer in Pennsylvania or a trader in London. From quantifying the hidden potential of a reservoir deep underground to ensuring the fair exchange of value in multi-billion dollar contracts, MMSCFD is the unwavering gold standard that keeps the world of natural gas flowing.

The content was very resourceful, educative and enriching.