Wireless Pressure Transmitters: IIoT Revolution

In the ever-evolving landscape of the Industrial Internet of Things (IIoT), a silent yet powerful transformation is underway. This revolution is fueled by the seamless flow of data, enabling smarter decisions, optimized processes, and unprecedented efficiency. At the heart of this data-driven ecosystem are the unsung heroes: wireless pressure transmitters. For instrumentation professionals and students aspiring to excel in this new era, a deep understanding of these devices is no longer optional, but essential.

This comprehensive blog post will delve into the world of wireless pressure transmitters in IIoT systems. We will explore their working principles, architectural integration, the immense benefits they bring, the challenges to consider, and a glimpse into their exciting future.

Deconstructing the Wireless Pressure Transmitter: More Than Just a Sensor

At its core, a pressure transmitter is a device that measures the pressure of a fluid or gas and converts it into a standardized electrical signal. However, a wireless pressure transmitter takes this a leap further by eliminating the need for cumbersome and expensive signal wiring.

So, how do they work? The process begins with a pressure sensing element. The most common types include:

- Piezoresistive Sensors: These sensors utilize the principle that the electrical resistance of a material changes when it’s subjected to mechanical stress. As process pressure deforms a diaphragm, the resistance of embedded strain gauges changes, providing a measure of the pressure.

- Capacitive Sensors: In these sensors, pressure applied to a diaphragm alters the distance between two parallel plates of a capacitor. This change in capacitance is then converted into an electrical signal corresponding to the pressure.

- Piezoelectric Sensors: Certain crystalline materials generate an electrical charge in response to applied mechanical stress. This piezoelectric effect is harnessed to measure dynamic pressure changes.

This raw electrical signal is then conditioned, amplified, and digitized by the transmitter’s internal electronics. The real innovation lies in the final stage: a low-power radio transceiver broadcasts this data to a central gateway or receiver.

Here’s a simplified block diagram illustrating the key components of a wireless pressure transmitter:

Block Diagram 1: Internal Components of a Wireless Pressure Transmitter

The Architectural Symphony: Integrating Wireless Transmitters into IIoT Systems

Wireless pressure transmitters don’t operate in a vacuum. They are integral components of a larger, interconnected IIoT architecture. The data they collect embarks on a journey from the plant floor to the cloud, enabling powerful analytics and actionable insights.

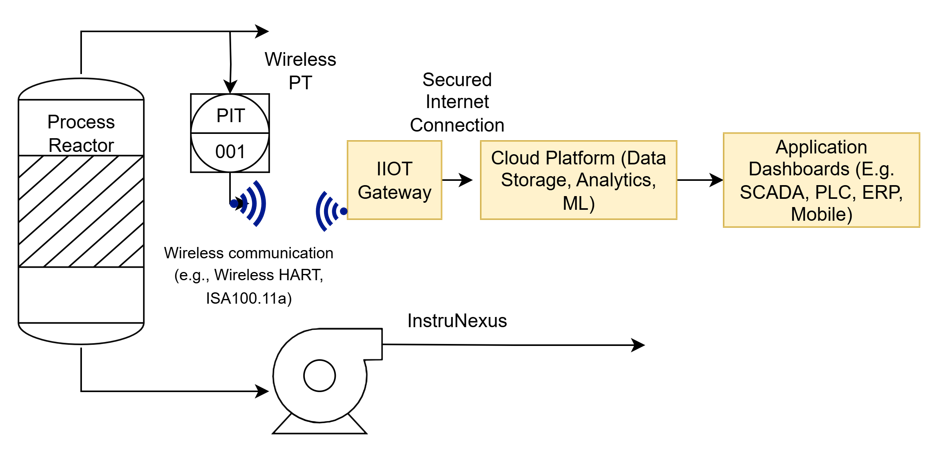

A typical IIoT system architecture incorporating wireless pressure transmitters can be visualized as follows:

Block Diagram 2: Wireless Pressure Transmitter in an IIoT Ecosystem

Let’s break down the key elements of this architecture:

- Field Devices: These are the wireless pressure transmitters themselves, deployed directly at the point of measurement.

- Wireless Network: This is the communication backbone. Two prominent standards dominate the industrial wireless space:

- WirelessHART (IEC 62591): An extension of the well-established HART communication protocol, it operates on a robust mesh network topology, ensuring high reliability and self-healing capabilities.

- ISA100.11a: A flexible and scalable standard that also supports mesh networking and is designed for a wide range of industrial applications. Both standards utilize the 2.4 GHz ISM band and employ techniques like frequency hopping to mitigate interference.

- Gateway: The gateway acts as a bridge between the wireless sensor network and the higher-level systems. It collects data from multiple transmitters, aggregates it, and securely transmits it to the cloud or local servers.

- Cloud Platform: This is where the real power of IIoT is unlocked. Cloud platforms provide scalable storage for vast amounts of sensor data. More importantly, they host advanced analytics engines, machine learning algorithms, and artificial intelligence models that can uncover hidden patterns, predict failures, and optimize processes.

- Applications and Control Systems: The insights generated in the cloud are then visualized on dashboards accessible to operators, engineers, and managers. This data can also be fed back into local control systems like Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems to enable automated control actions.

The Unmistakable Advantages: Why Go Wireless?

The adoption of wireless pressure transmitters is not just a trend; it’s a strategic move that offers a multitude of benefits:

- Reduced Installation Costs and Time: The most significant advantage is the elimination of extensive and costly cabling. This is particularly beneficial in remote, hazardous, or difficult-to-reach locations. Installation time is drastically reduced from days to mere hours.

- Enhanced Flexibility and Scalability: Need to add a new measurement point? With wireless, it’s as simple as mounting a new transmitter and configuring it on the network. This unparalleled flexibility allows for easy expansion and reconfiguration of monitoring systems as process needs evolve.

- Improved Asset Monitoring and Predictive Maintenance: Wireless transmitters make it economically viable to monitor a wider range of assets, including those that were previously deemed too expensive to wire. The continuous stream of data from these sensors is the lifeblood of predictive maintenance strategies. By analyzing pressure trends, anomalies, and deviations, potential equipment failures can be predicted well in advance, minimizing unplanned downtime and extending asset life.

- Increased Safety: In hazardous environments, wireless technology minimizes the need for personnel to enter potentially dangerous areas for installation and maintenance. Furthermore, the continuous monitoring of critical pressure points can provide early warnings of leaks or overpressure situations, preventing accidents.

- Data-Driven Decision Making: By providing a wealth of previously unavailable data, wireless pressure transmitters empower engineers and managers to make more informed decisions, leading to process optimization, improved product quality, and increased overall equipment effectiveness (OEE).

Navigating the Challenges: A Realistic Perspective

While the benefits are compelling, it’s crucial to be aware of the challenges associated with implementing wireless pressure transmitters:

- Power Management: Most wireless transmitters are battery-powered. While battery life has significantly improved, it remains a key consideration. Careful planning and the use of energy-efficient protocols are essential to minimize maintenance interventions for battery replacement. The advent of energy harvesting technologies holds promise for a battery-less future.

- Network Reliability and Interference: Industrial environments are often rife with electromagnetic interference. While standards like WirelessHART and ISA100.11a are designed to be robust, careful network planning, including site surveys, is necessary to ensure reliable communication.

- Cybersecurity: As with any connected system, security is paramount. The wireless transmission of process data introduces potential vulnerabilities. A multi-layered security approach is essential, encompassing:

- Device-level security: Authentication and encryption of data at the transmitter itself.

- Network security: Secure gateways, firewalls, and intrusion detection systems.

- Data security: Encryption of data both in transit and at rest in the cloud.

- Integration with Legacy Systems: Integrating new wireless systems with existing wired infrastructure and legacy control systems can sometimes be complex. The use of standardized protocols and gateways with multiple communication capabilities is key to a smooth integration.

- Initial Investment: While the long-term return on investment is often significant, the initial cost of wireless transmitters and gateway infrastructure can be a consideration.

The Future is Wireless: What’s Next for Pressure Measurement?

The evolution of wireless pressure transmitters is far from over. Several exciting trends are shaping their future:

- Miniaturization and Lower Power Consumption: Advancements in micro-electro-mechanical systems (MEMS) technology are leading to smaller, more energy-efficient sensors.

- Energy Harvesting: The ultimate goal is to create self-powered transmitters that can harvest energy from their environment, such as vibrations, thermal gradients, or ambient light. This will eliminate the need for batteries entirely.

- Edge Computing: More intelligence will be embedded directly into the transmitters and gateways. This “edge computing” will allow for localized data processing and analysis, reducing the amount of data that needs to be transmitted to the cloud and enabling faster response times for critical applications.

- Artificial Intelligence and Machine Learning at the Edge: Future transmitters may incorporate AI and ML algorithms to perform real-time diagnostics on the data they collect, providing not just raw pressure readings but also actionable insights directly from the device.

- Enhanced Security Protocols: As cyber threats evolve, so too will the security features embedded in wireless devices and networks, ensuring the integrity and confidentiality of industrial data.

Conclusion: Embracing the Wireless Paradigm

Wireless pressure transmitters are more than just a technological novelty; they are a cornerstone of the Industrial Internet of Things. They are empowering industries to break free from the constraints of traditional wired infrastructure, unlocking a new realm of possibilities for process optimization, predictive maintenance, and enhanced safety.

For instrumentation professionals, mastering the principles and applications of these devices is crucial for staying relevant in a rapidly changing industry. For students, a solid understanding of wireless sensor technology will open doors to exciting career opportunities at the forefront of industrial innovation.

The journey to a fully connected and intelligent industrial landscape is well underway, and wireless pressure transmitters are leading the charge, one data point at a time. The message is clear: the future of industrial instrumentation is wireless, and it’s happening now.