Recent Updates

An imperative in the high-stakes world of industrial processing is the uncompromising pursuit of safety. When processes involve hazardous materials or extreme conditions, the consequences of failure can be catastrophic. This is where the concept of Safety Integrity Level (SIL) emerges as a cornerstone of modern risk management. A SIL...

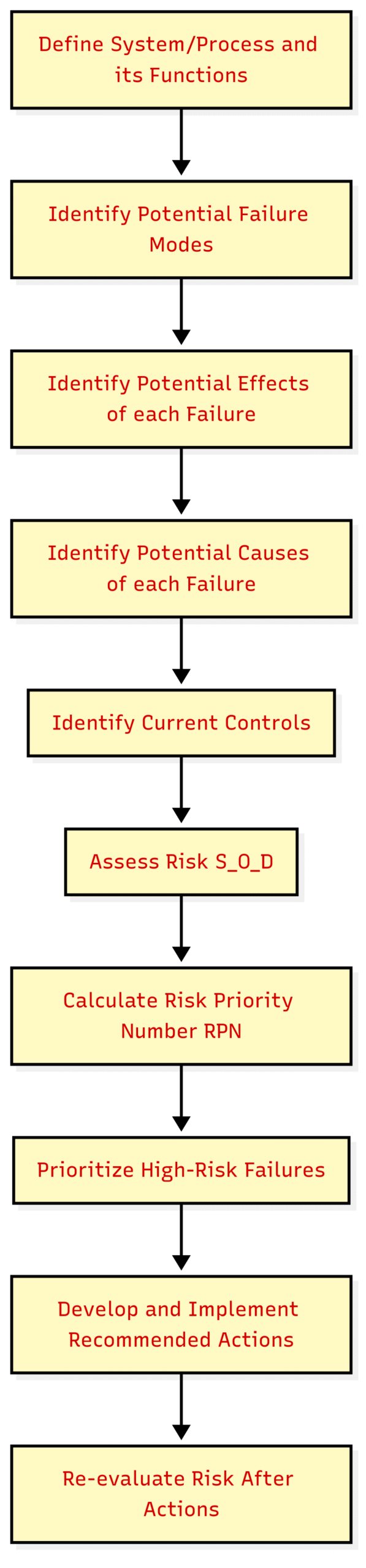

Risk Graph, LOPA, and FMEA: SIL Assessment Methods Compared In the realm of industrial automation and process safety, ensuring the reliability of safety systems is not just a matter of compliance; it’s a critical imperative to protect human lives, the environment, and valuable assets. Central to this endeavor is the...

SIL Determination Explained: IEC 61508 vs. IEC 61511 Approach In the world of industrial automation and process safety, ensuring the reliability of safety systems is not just a matter of good practice; it’s a critical necessity mandated by stringent international standards. Two of the most pivotal standards in this domain...

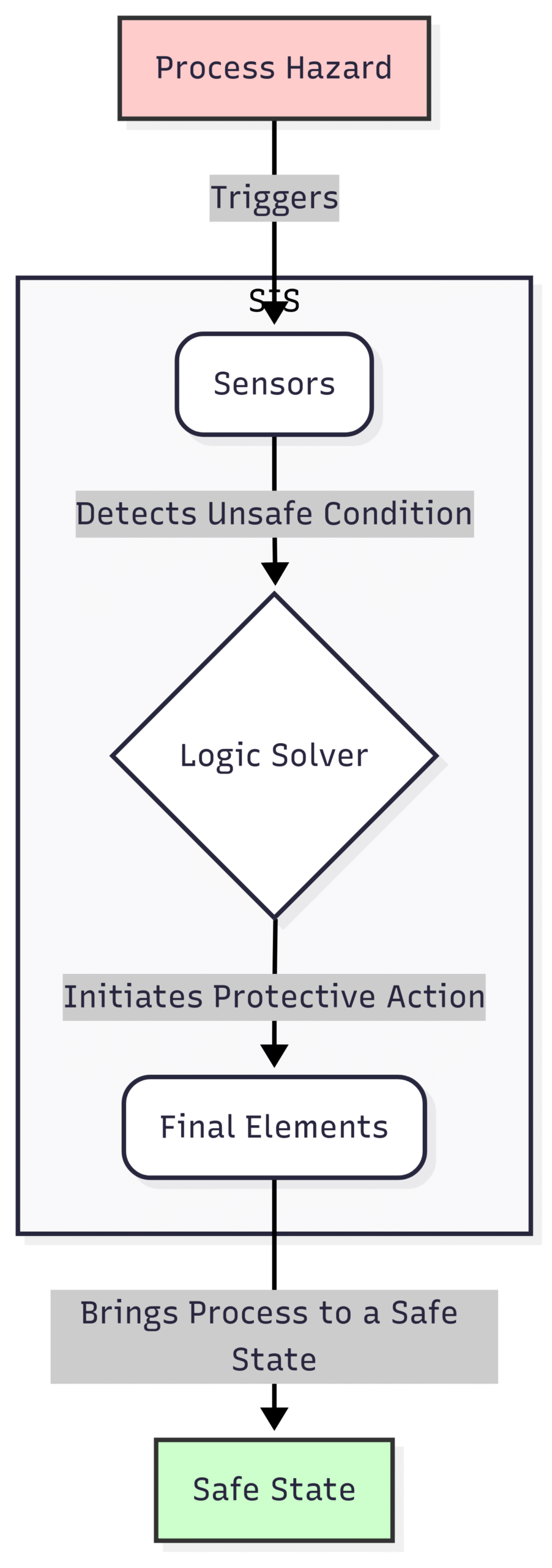

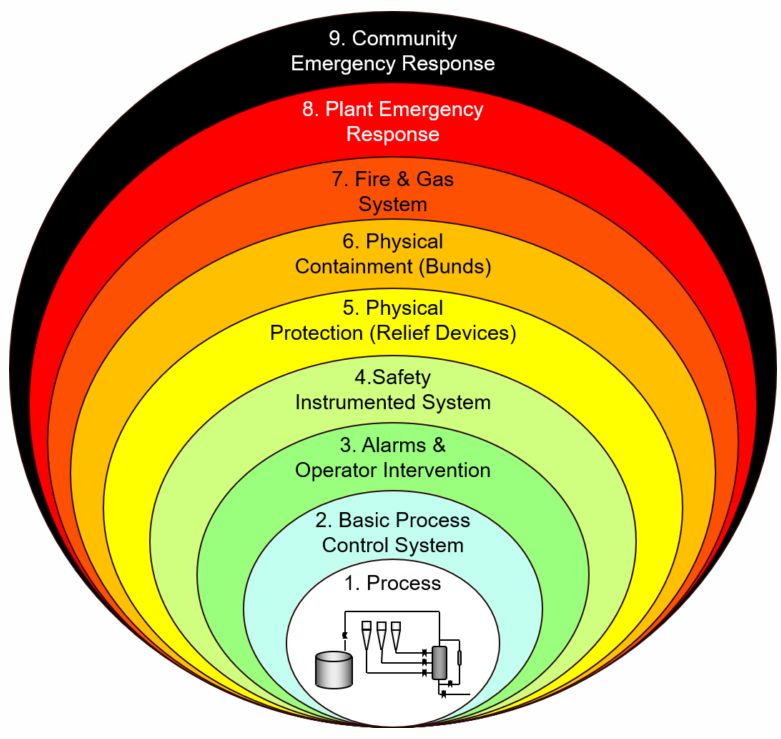

What Is SIL? Safety Integrity Levels In the intricate and often hazardous world of industrial operations, from sprawling chemical plants and offshore oil rigs to complex manufacturing facilities, ensuring safety is not just a priority; it’s a fundamental necessity. As technology advances and processes become more automated, the systems responsible...

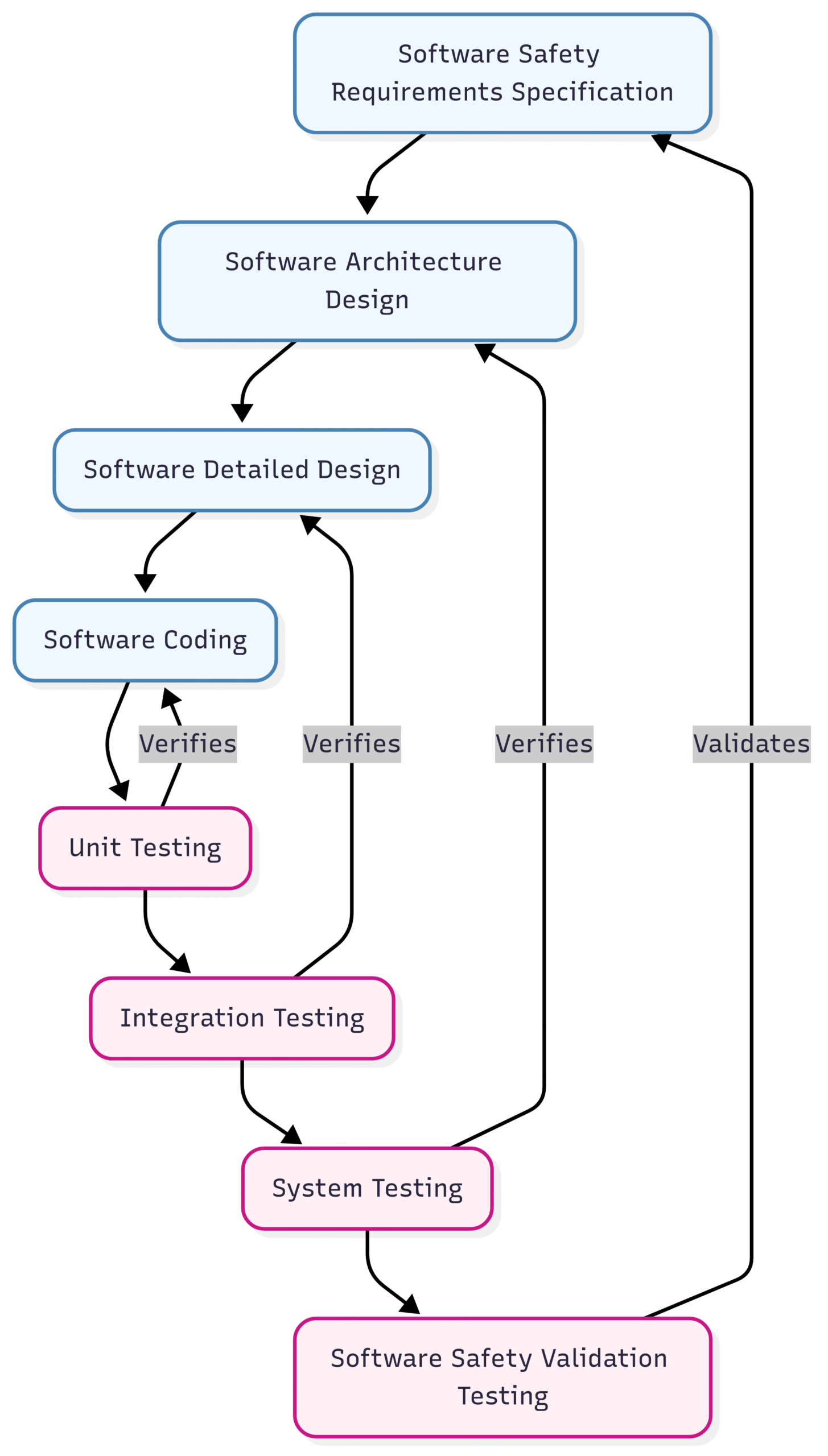

IEC 61508 Part 2 and 3 – Hardware and Software Requirements Explained In the world of industrial automation and safety-critical systems, ensuring that equipment operates safely and reliably is not just a matter of good practice; it’s a fundamental necessity. The international standard IEC 61508 provides a rigorous framework for...

Achieving SIL Certification with IEC 61508 Compliance: A Comprehensive Guide In today’s increasingly automated and complex industrial landscape, ensuring the safety of processes and systems is not just a priority, it’s a necessity. From chemical processing plants to nuclear power stations and complex machinery, the potential for catastrophic failure is...

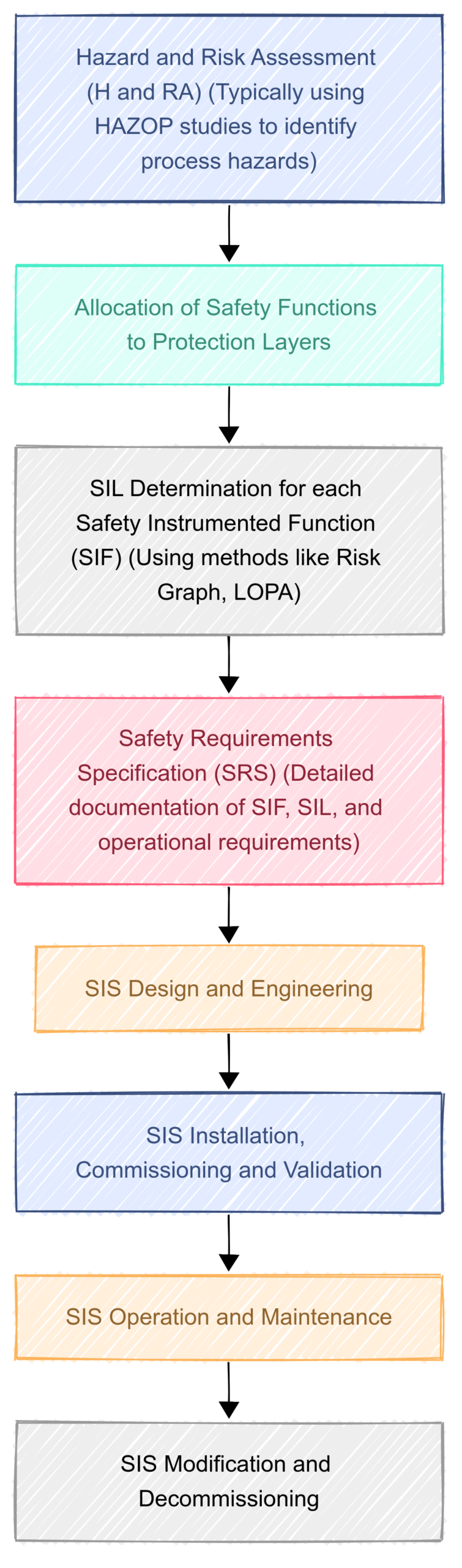

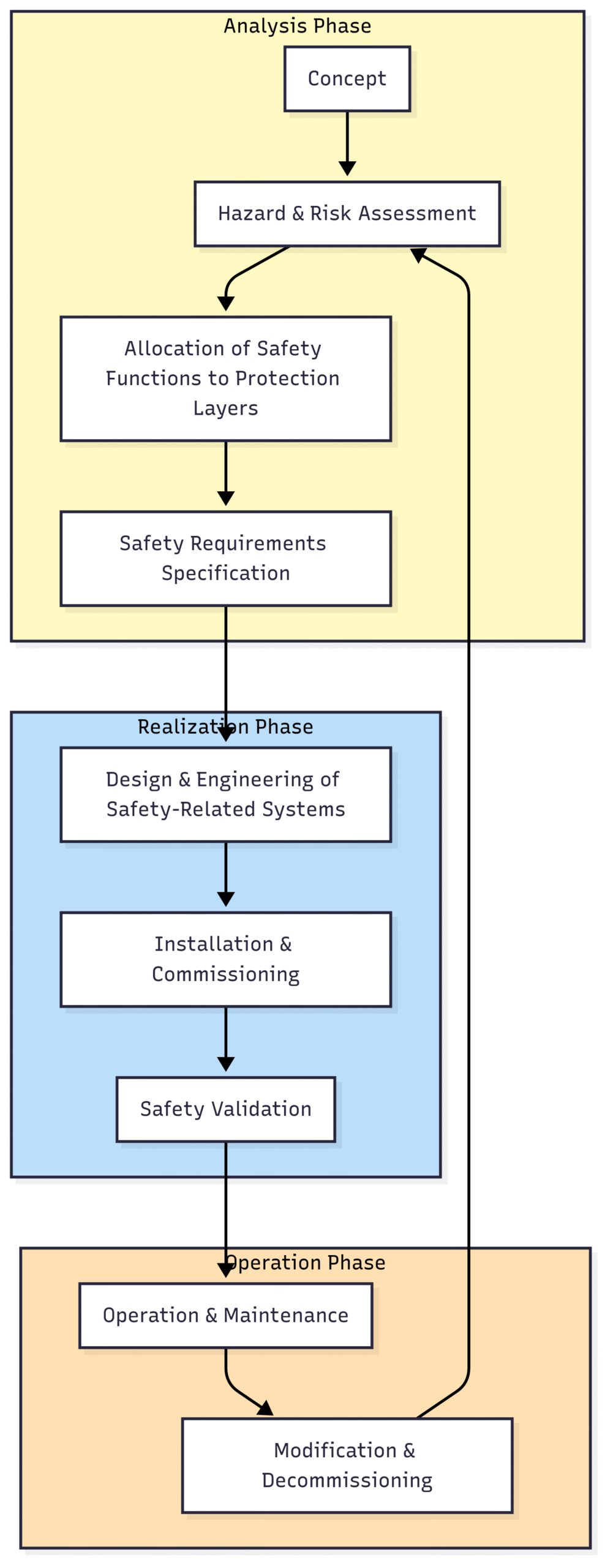

The Safety Lifecycle According to IEC 61508: A Blueprint for Functional Safety In today’s increasingly automated world, the safe operation of industrial processes and systems is paramount. From chemical plants and power stations to complex machinery and transportation systems, the potential for catastrophic failures necessitates a rigorous and systematic...

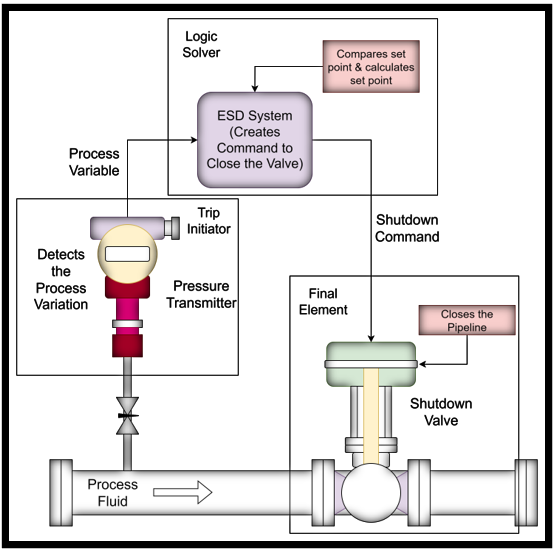

A Deep Dive into Functional Safety: How IEC 61508 Governs Safety Instrumented Systems (SIS) In the world of industrial processes, from chemical plants and oil refineries to power generation and manufacturing, the silent hum of machinery and the steady flow of materials are the sounds of productivity. But beneath this...

IEC 61508 Overview: The Foundation of Functional Safety Standards In our increasingly automated world, the silent sentinels of safety are often complex electronic systems. From the emergency shutdown systems in a chemical plant to the braking control in a modern vehicle, these systems are the invisible guardians that prevent catastrophic...