Recent Updates

The Unseen Guardian: Why Functional Safety is Non-Negotiable in Process Industries In the heart of sprawling industrial landscapes, where colossal networks of pipes, vessels, and reactors hum with immense energy, a silent, ever-vigilant guardian stands watch. This guardian is not a person in a hard hat, but a deeply embedded...

Understanding Functional Safety: Key Principles and Lifecycle Phases In our increasingly automated world, from the car you drive to the chemical plant down the road, complex systems are at the heart of modern life. But what happens when these systems fail? The consequences can be catastrophic, leading to financial loss...

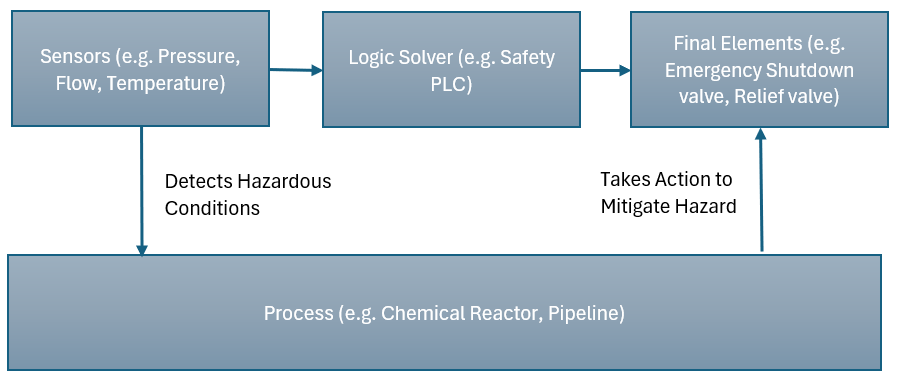

What Is Functional Safety? A Beginner’s Guide to IEC 61511 & IEC 61508 In today’s increasingly complex and interconnected industrial world, safety is paramount. While traditional safety measures focus on preventing accidents through robust design and operational procedures, functional safety takes a more specific approach. It deals with the...

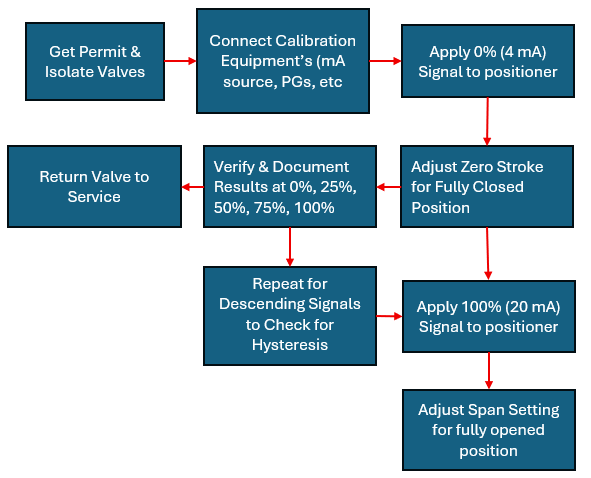

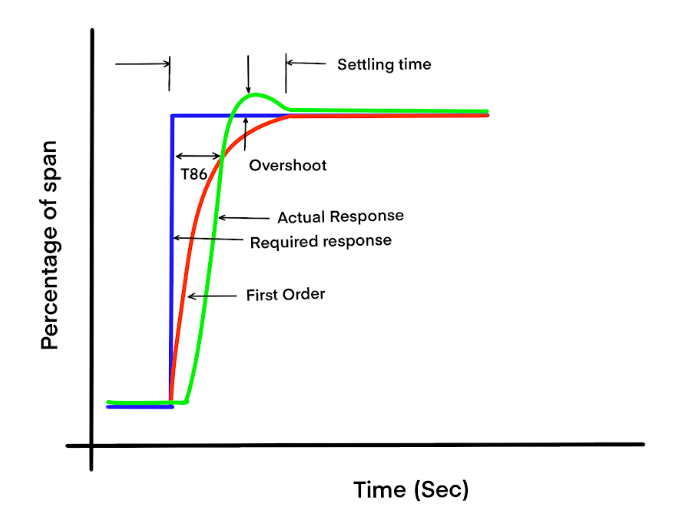

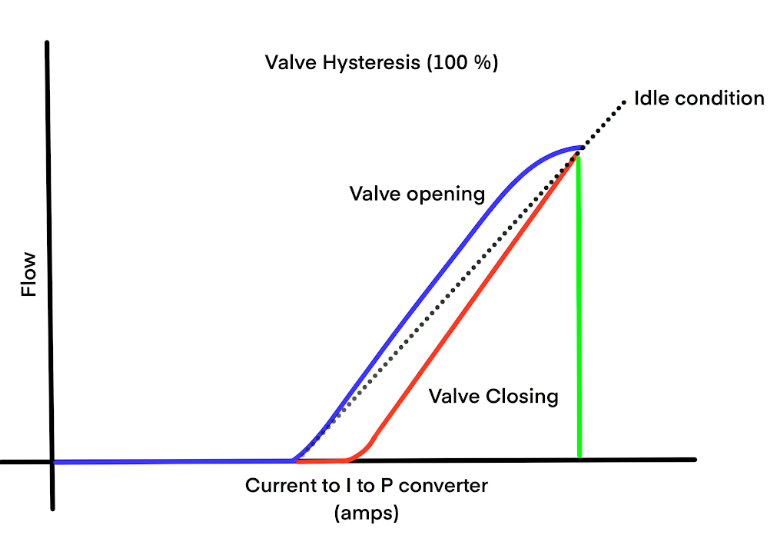

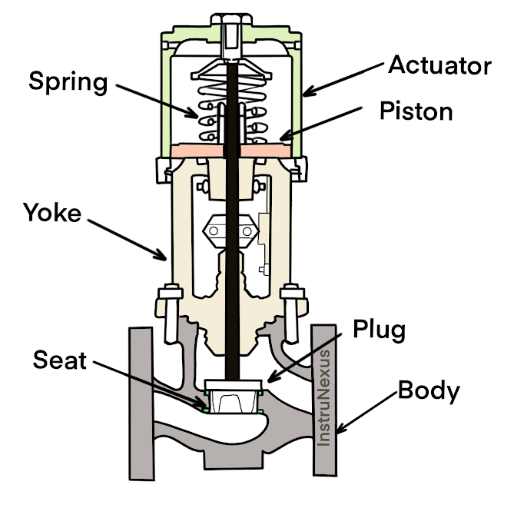

Best Practices for Control Valve Calibration and Stroke Checking In the intricate world of industrial process control, the humble control valve plays a pivotal role. It is the final control element, the muscle that acts on the commands of the brain – the distributed control system (DCS) or programmable logic...

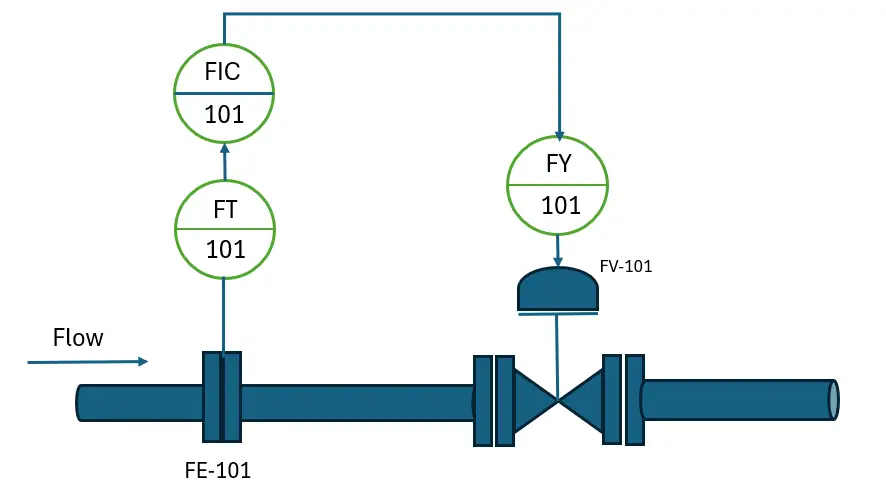

How to Interpret Control Valve Symbols on P&IDs (With Examples) In the intricate world of process industries, Piping and Instrumentation Diagrams (P&IDs) serve as the definitive roadmap. These detailed drawings provide a graphical representation of the piping, equipment, and instrumentation within a processing plant. For engineers, technicians, and operators, the...

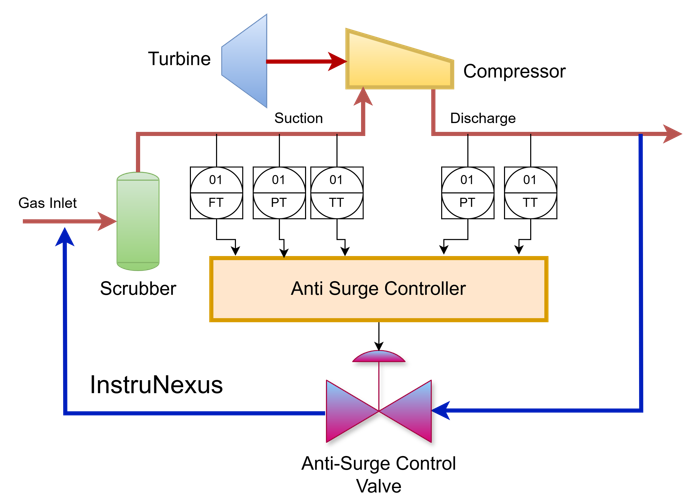

In the heart of many industrial processes, from oil and gas refining to chemical production and power generation, lies a critical piece of rotating equipment: the centrifugal compressor. These machines are the workhorses responsible for increasing the pressure of a gas, a fundamental step in numerous applications. However, lurking within...

In the world of process control, the control valve plays a pivotal role. It is the final control element, the muscle that translates the brain’s (the controller’s) commands into physical action, meticulously regulating the flow of fluids to maintain process variables at their desired setpoints. However, the performance of this...

In the intricate dance of industrial processes, precision is paramount. Whether it’s maintaining a specific temperature in a reactor, regulating pressure in a pipeline, or ensuring a consistent flow rate for a critical ingredient, the ability to maintain a process variable at its desired setpoint is the bedrock of efficiency...

Actuators for Control Valves: A Detailed Comparison of Pneumatic, Electric, and Hydraulic Options In the intricate world of industrial process control, the control valve stands as the final control element, the muscle that ultimately implements the decisions of the plant’s control system. But what gives this muscle its power? The...